Cobalt-rich crusting thickness measuring method based on multi-beam receiving technology

A cobalt-rich crust and measurement method technology, applied in the field of geological exploration, can solve problems such as measurement errors, and achieve the effects of high efficiency, high thickness measurement accuracy, and large measurement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

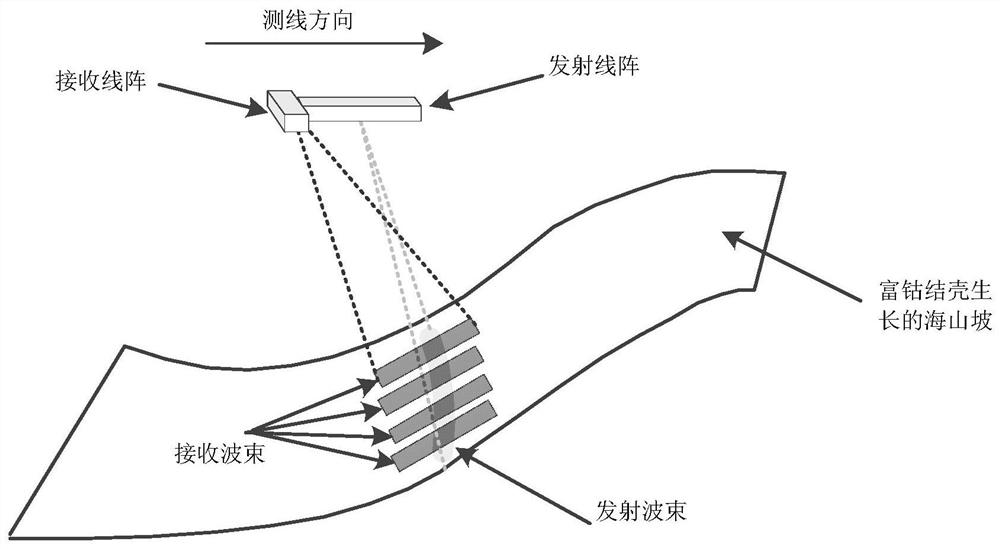

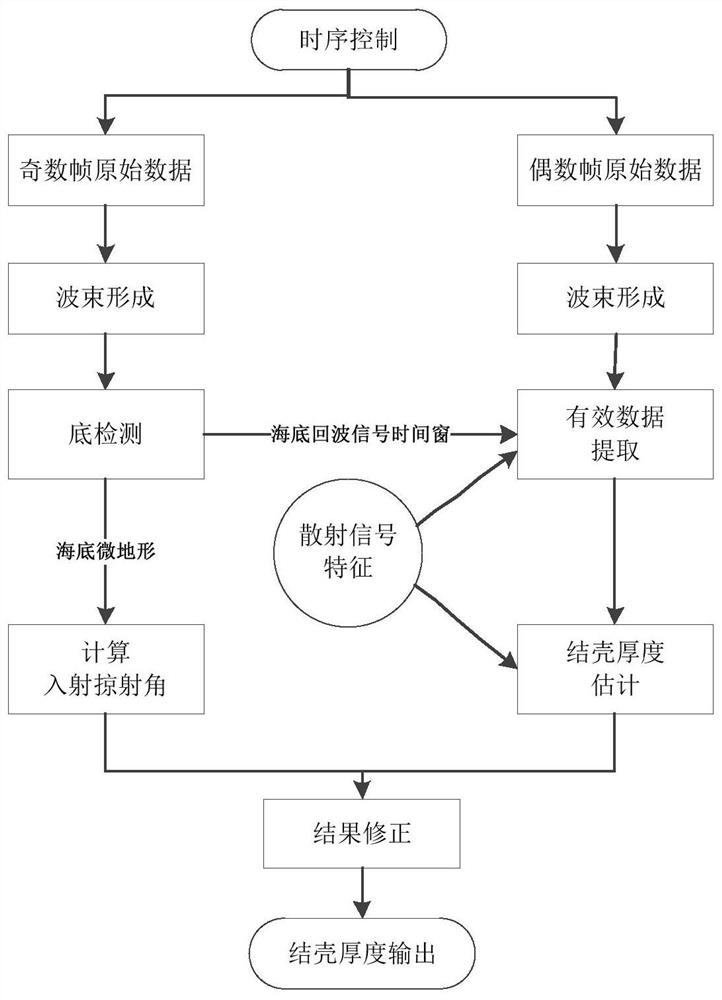

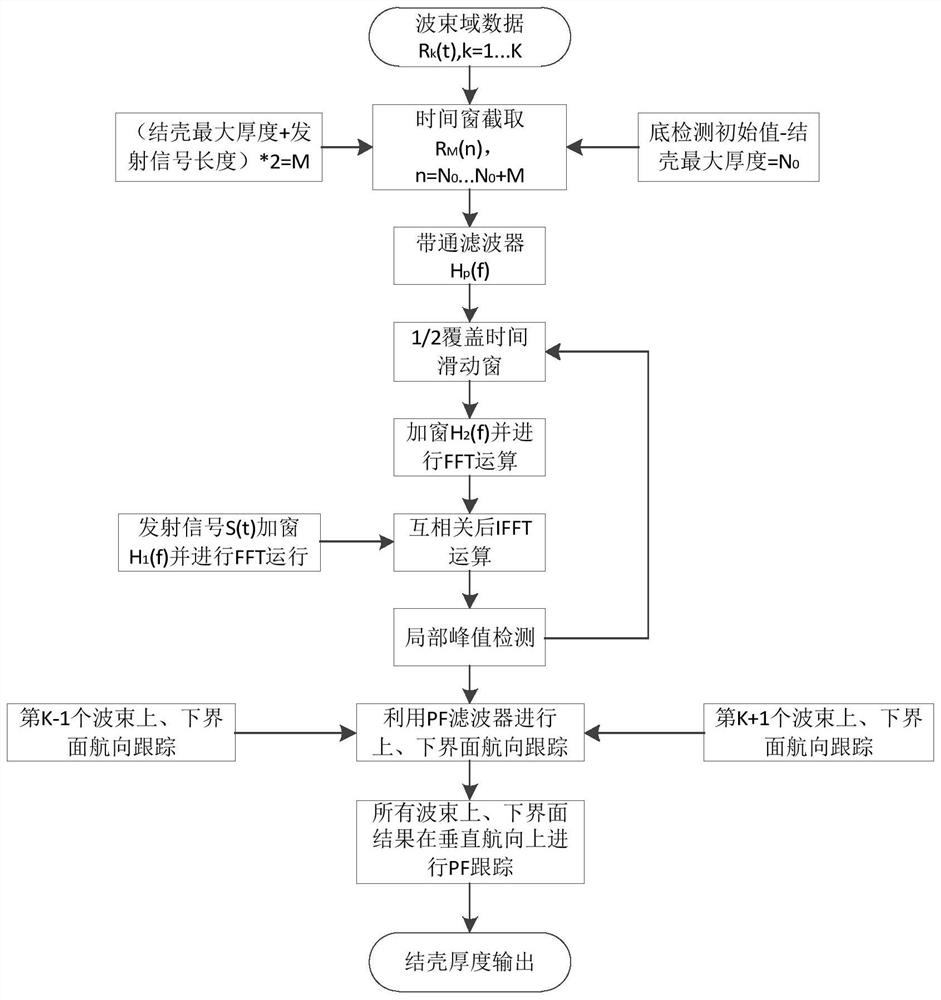

[0017] The method of the present invention utilizes the multi-beam receiving technology, and the transmitting line array and the receiving line array adopt a T-shaped arrangement, such as figure 1 As shown, the transmitting line array is parallel to the direction of the survey line (the heading of the submersible carrier on which the crust thickness measurement equipment is installed), and the receiving line array is perpendicular to the direction of the survey line. Data processing flow such as figure 2 As shown, the narrowband high-frequency PCW signal is first transmitted (here, the number of narrowband high-frequency signal transmissions is defined as an odd number of frames), and multiple receiving strips can be obtained by using the receiving beamforming technology, and then multiple The seabed echo signal at the measurement point and the backscattering signal at the interface between the seawater and the seabed are strong. The bottom detection algorithm is used to calc...

Embodiment 2

[0020] In this embodiment, the laboratory measurement and verification is carried out on the imitation crust sample mounted on the plate. The thickness of the imitation sample is 100mm, and the area is 500*500mm. Firstly, place the transmitting transducer at a height of 1100mm directly above the imitation sample, the transmitting beam of the transducer is in a 90° state with the imitation sample, the pulse width of the transmitting signal is 0.1ms, the center frequency is 100kHz, 100 consecutive transmissions, and the echo signal is received Finally, the method is used to calculate the thickness of the imitation sample, and the calculation results are statistically analyzed. The average value of the calculated thickness of the imitation sample is 98.8mm, and the variance is 1.4*10 -17. Adjust the angle of the imitation sample so that it is in the state of 80° with the beam emitted by the transducer, simulate the undulating and inclined state of the seabed, transmit the same s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com