Automatic powder scattering and disinfecting platform for silkworm body and silkworm rearing bed

A silkworm seat and automatic technology, applied in the field of sericulture machinery, can solve the problems of silkworm farmers' physical injuries, harsh working environment, and low work efficiency, and achieve the effects of reducing dust hazards, improving operating efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

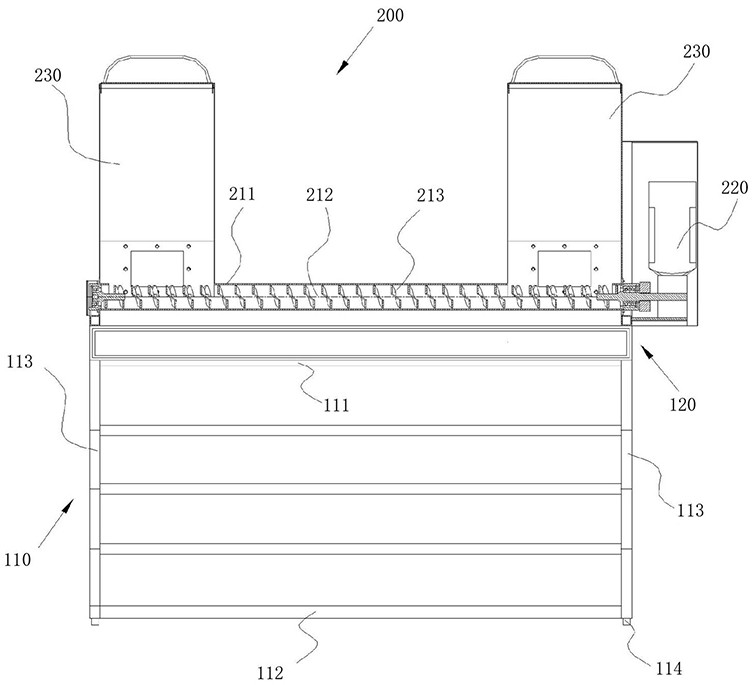

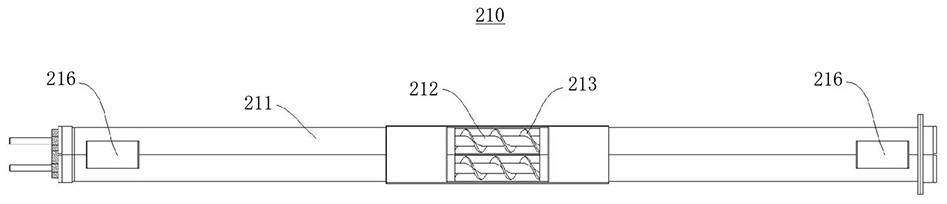

[0040] Such as Figure 1-5 As shown, a silkworm body and silkworm seat automatic powdering and disinfection platform includes a supporting part 100 and a powdering mechanism 200, the powdering mechanism 200 is connected to the supporting part 100, and the supporting part 100 is used to support the dusting Powder body 200. The powder spreading mechanism 200 comprises a powder spreading device 210 and a driving device 220, and the powder spreading device 210 comprises a powder spreading pipe 211 and at least one screw shaft, such as figure 2 As shown, this embodiment only exemplifies that the powder spreading device 210 includes two screw shafts. All the screw shafts are arranged in the powder spreading pipe 211, and all the screw shafts are arranged side by side laterally, each of the screw shafts includes a main shaft 212 and a helical blade 213, and each of the helical blades 213 is arranged along the corresponding The main shaft 212 is arranged axially, and all the main s...

Embodiment 2

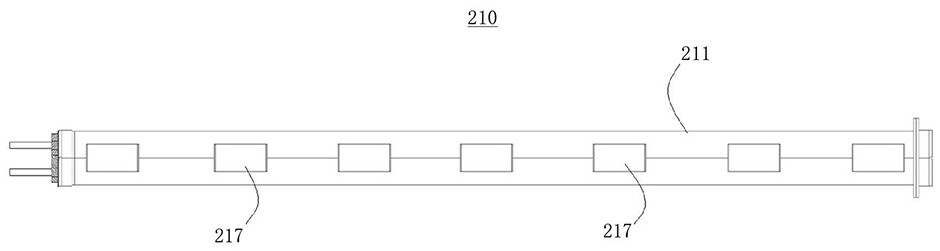

[0052] Such as Figure 6 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1. The difference is that each of the main shafts 212 is connected with a gear 218, and each of the gears 218 is fixedly connected to the end of the corresponding main shaft 212. Two adjacent gears 218 are meshed and connected, and the driving device 220 is connected to one of the main shafts 212 . When the main shaft 212 rotates under the action of the driving device 220 , it can drive the other main shafts 212 to rotate due to the meshing relationship. The driving device 220 is connected to one of the main shafts 212 , or connected to the gear 218 through the corresponding gear 218 .

[0053] The powder spreading device 210 includes at least two helical shafts, and two adjacent helical blades 213 rotate in the same direction. Such as Figure 7 As shown, this embodiment only exemplifies that the powder spreading device 210 includes two screw shafts. Due to t...

Embodiment 3

[0055] Such as Figure 8 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, the difference is that the powder spreading pipe 211 is provided with a powder inlet 216, and the powder spreading mechanism 200 includes a powder storage box 230, so The powder storage box 230 is provided with the powder outlet, and the powder inlet 216 is connected and communicated with the powder outlet. The powder storage box 230 is arranged in the middle part of the powder spreading pipe 211, and the powder storage box 230 is funnel-shaped, which is convenient for powdery substances to be packed into the powder storage box 230. The top of the powder storage box 230 A cover plate is connected to prevent the powdery substance from getting damp in the air and losing the ability to kill viruses. Further, the cover plate is hinged on the top of the powder storage box 230 .

[0056] Such as Figure 9As shown, the powder spreading device 210 includes a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com