Automatic quantitative evaporation concentration device and corresponding concentration method

An evaporative concentration and quantitative concentration technology, applied in the field of evaporative concentration chemical analysis, can solve the problems of impact measurement, labor cost, inaccurate concentration ratio, etc., and achieve the effect of reducing impact and saving labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

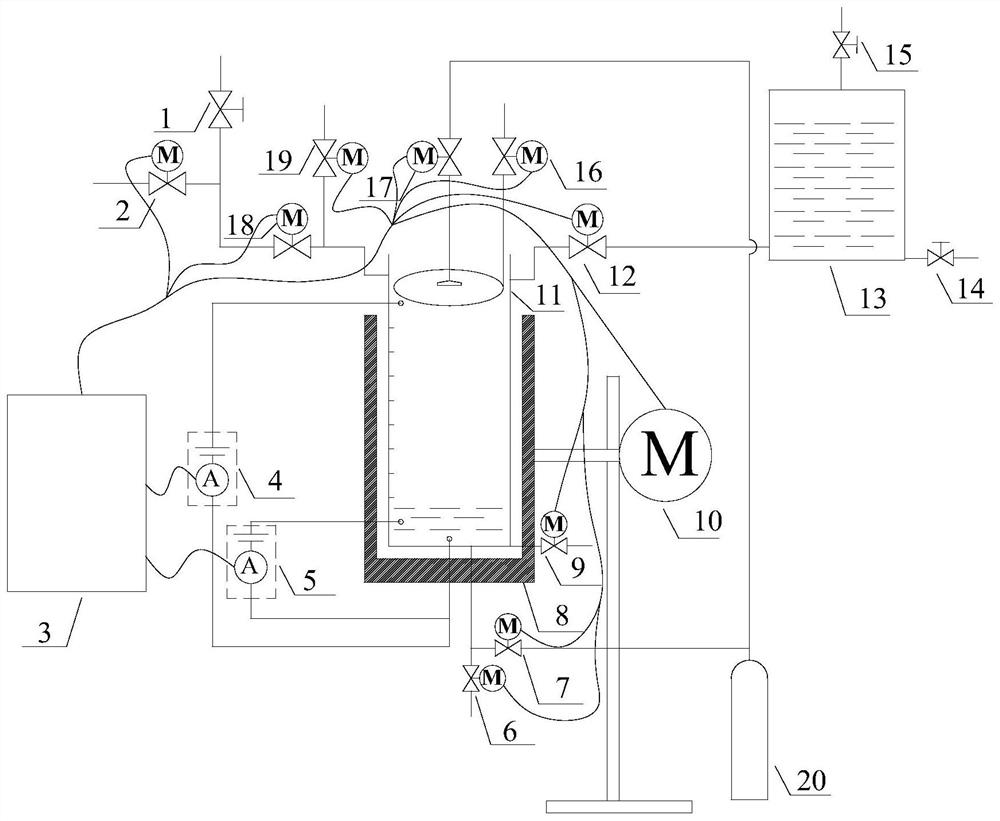

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Take water vapor sampling and concentrated iron measurement as an example, such as figure 1 As shown, open the sampling cut-off valve 1 connected to the sample water, the quantitative evaporation concentration control box 3 collects the quantitative sampling induction circuit 4 in the open circuit state, controls the sampling electric valve 18 to open, controls the sampling bypass electric valve 2 to close, and the water sample automatically Enter in the evaporating and concentrating cup 11, the total amount of sampling is 200ml, and the sampling flow rate is 50ml / min, open the dosing electric valve 19 and add concentrated hydrochloric acid 1ml in the sampling process, prevent iron corrosion product from being adsorbed on the cup wall of the evaporating and concentrating cup, and then Close the dosing electric valve 19, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com