Treatment device for treating waste gas containing dichloroethane

A processing device, dichloroethane technology, applied in the direction of gas treatment, organic chemistry, transportation and packaging, etc., can solve the problem of low work efficiency, to achieve the effect of ensuring work efficiency and desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

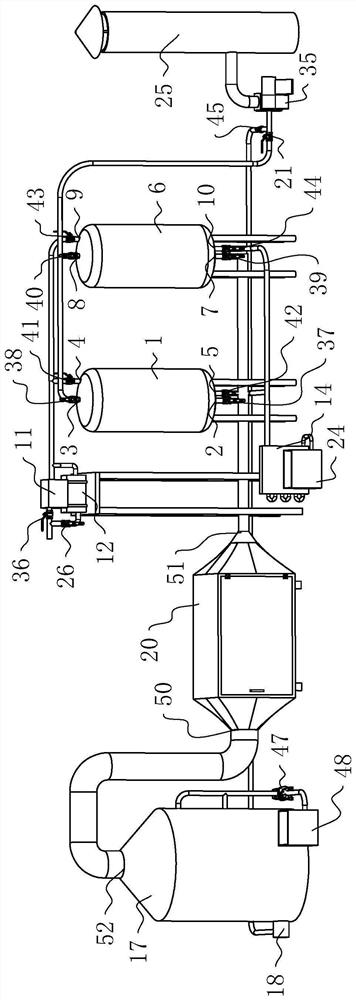

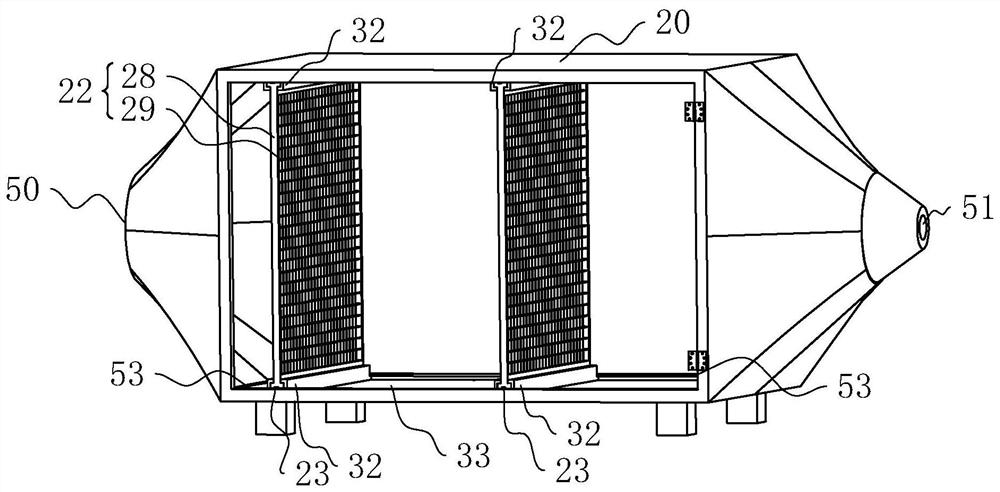

[0042] refer to figure 1 , the treatment device used to treat waste gas containing dichloroethane includes a washing tower 17, a dry filter 20, an adsorption tower 1, a second adsorption tower 6 and an exhaust tube 25, and the adsorption tower 1 and the second adsorption tower 6 pass through a pipeline A condenser 14 is connected. The outlet of the condenser 14 is connected with a recovery pool 24 . The washing tower 17 is provided with a washing inlet 18. After the waste gas enters through the washing inlet 18, it undergoes washing, filtering, adsorption and other operations, and finally enters the atmosphere from the exhaust pipe 25. The dichloroethane in the exhaust gas passes through the adsorption tower 1 and the second adsorption tower 6, and finally condenses into a liquid state through the condenser 14, and flows into the recovery pool 24, which is convenient for the staff to recycle.

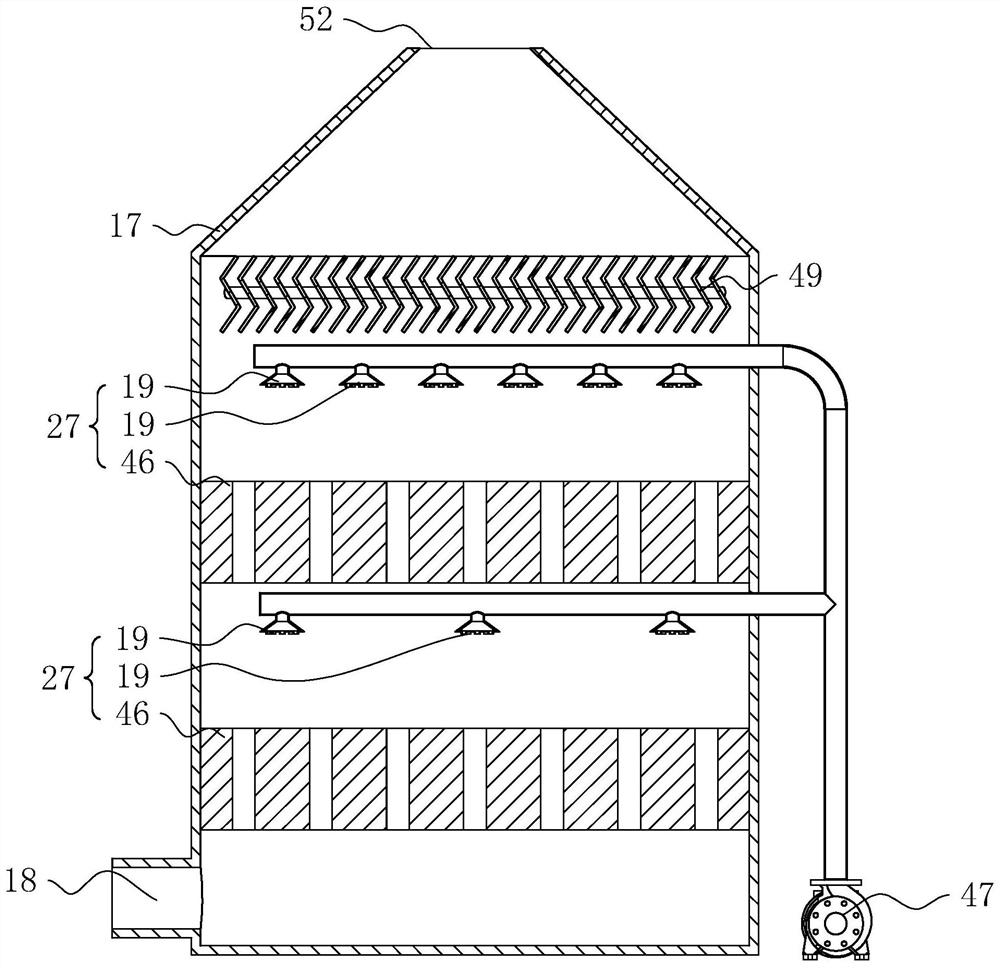

[0043] refer to figure 2The washing inlet 18 is located on the side wall of the...

Embodiment 2

[0063] refer to Figure 8 The difference between embodiment 2 and embodiment 1 is that the discharge port 5 and the feed port 4 of the adsorption tower 1 form a closed loop, and the second discharge port 10 and the second feed port 9 of the second adsorption tower 6 Also form closed loop, two closed loops are connected with vacuum pump 13 jointly by pipeline, and the outlet of vacuum pump 13 is connected with condenser 14, and vacuum pump 13 can reduce the pressure drop in adsorption tower 1 and the second adsorption tower 6, utilizes step-down desorption The principle of further improving the desorption effect.

[0064] refer to Figure 8 , the closed circuit formed by the discharge port 5 and the feed port 4, and the closed circuit formed by the second discharge port 10 and the second feed port 9 are jointly connected with an emergency pipeline 15, and the emergency pipeline 15 communicates with the inlet of the blower fan 35, An emergency valve 16 is connected to the emer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com