Preparation process of novel catalyst for isobutylbenzene synthesis process

A technology for the synthesis of isobutylbenzene and isobutylbenzene, applied in the directions of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as expensive metal potassium, unfavorable industrial application, and reduced production costs, and achieve Facilitate procurement, improve market competitiveness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

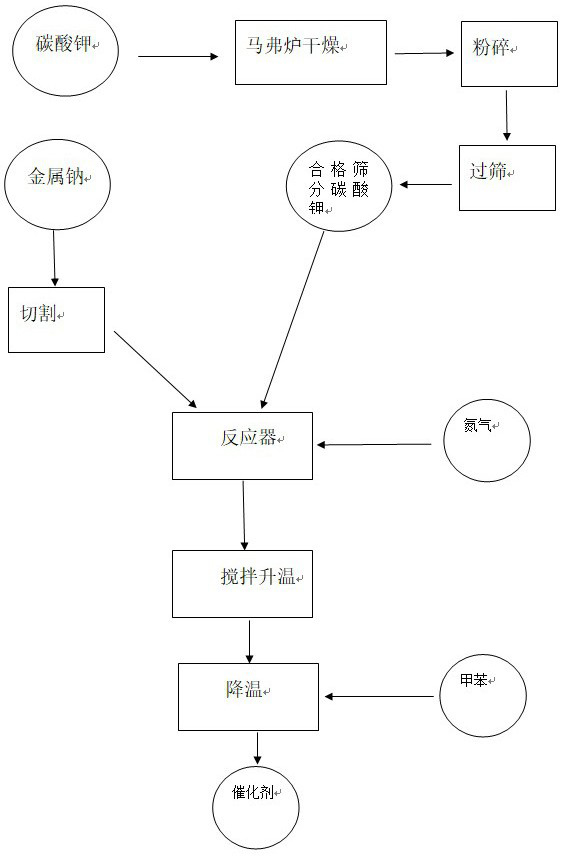

Image

Examples

Embodiment 1

[0020] Example 1: Potassium carbonate is placed in a stainless steel tray, placed in a muffle furnace to heat up and dry, the temperature is controlled at 200°C, and the drying time is 1 hour. After drying, it is pulverized with a pulverizer, sieved with a sieve, and a 100-mesh sieve is taken. 30 grams of sieved and added to the flask, remove the oxide layer of sodium metal with a wallpaper knife, cut into small pieces, add 12 grams of sodium metal to the flask, turn on nitrogen protection, heat with an oil bath, set the temperature at 240°C, and stir at a speed of 1000 revolutions, observe the internal state of the flask, the internal material changes from a loose type to an alloy state and then maintains the temperature for 0.5 hours. Cool down to 40°C and add toluene for protection. The catalyst was used to carry out the synthesis test of isobutylbenzene, and the conversion rate was determined to be 45.2%.

Embodiment 2

[0021] Example 2: Put potassium carbonate in a stainless steel tray, place it in a muffle furnace to heat up and dry, control the temperature at 250°C, and dry for 1 hour. After drying, grind it with a pulverizer, sieve it with a sieve, and take a 100-mesh sieve. Sieve 30 grams of sodium metal, add it to the flask, turn on the nitrogen protection, remove the oxide layer of the metal sodium with a wallpaper knife, cut it into small pieces, add 9 grams of metal sodium to the flask, heat with an oil bath, set the temperature at 220 ° C, and stir at a speed of 1100 revolutions, observe the internal state of the flask, the internal material changes from a loose type to an alloy state and then maintains the temperature for 0.5 hours. Cool down to 45°C and add toluene for protection. The catalyst was used to carry out the synthesis test of isobutylbenzene, and the conversion rate was determined to be 43.5%.

Embodiment 3

[0022] Embodiment 3: Embodiment 2: Potassium carbonate is filled in the stainless steel tray, is placed in the muffle furnace and is heated and dried, and the temperature is controlled at 250 ℃, and the drying time is 1 hour. After drying, pulverize with a pulverizer, sieve with a sieve, and take Sieve 30 grams of 150-mesh sieve, add to the flask, remove the oxide layer of metal sodium with a wallpaper knife, cut into small pieces, add 12 grams of metal sodium to the flask, turn on nitrogen protection, heat with an oil bath, set the temperature to 240 ℃, the stirring speed is 1300 rpm, and the internal state of the flask is observed. The internal material changes from a loose type to an alloy state and then maintains the temperature for 0.5 hours. Cool down to 40°C and add toluene for protection. The catalyst was used to carry out the synthesis test of isobutylbenzene, and the conversion rate was determined to be 52.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com