Sampling device for regularly detecting microorganisms

A sampling device and microbial technology, applied in the direction of biological material sampling methods, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of non-reusable, waste of resources, etc., to reduce the risk of pollution, high work efficiency, improve The effect of sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

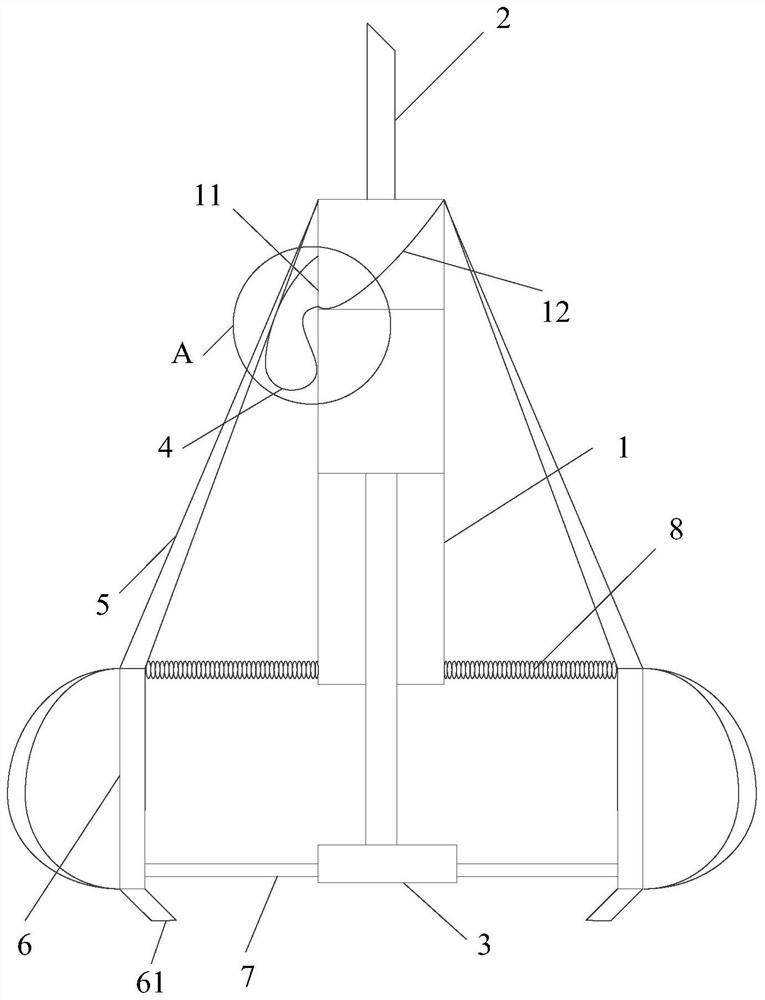

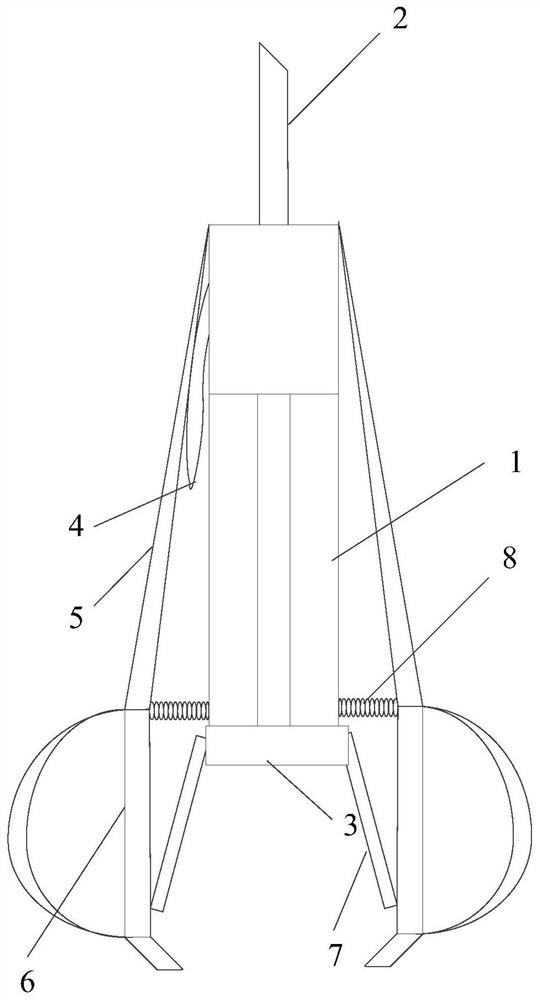

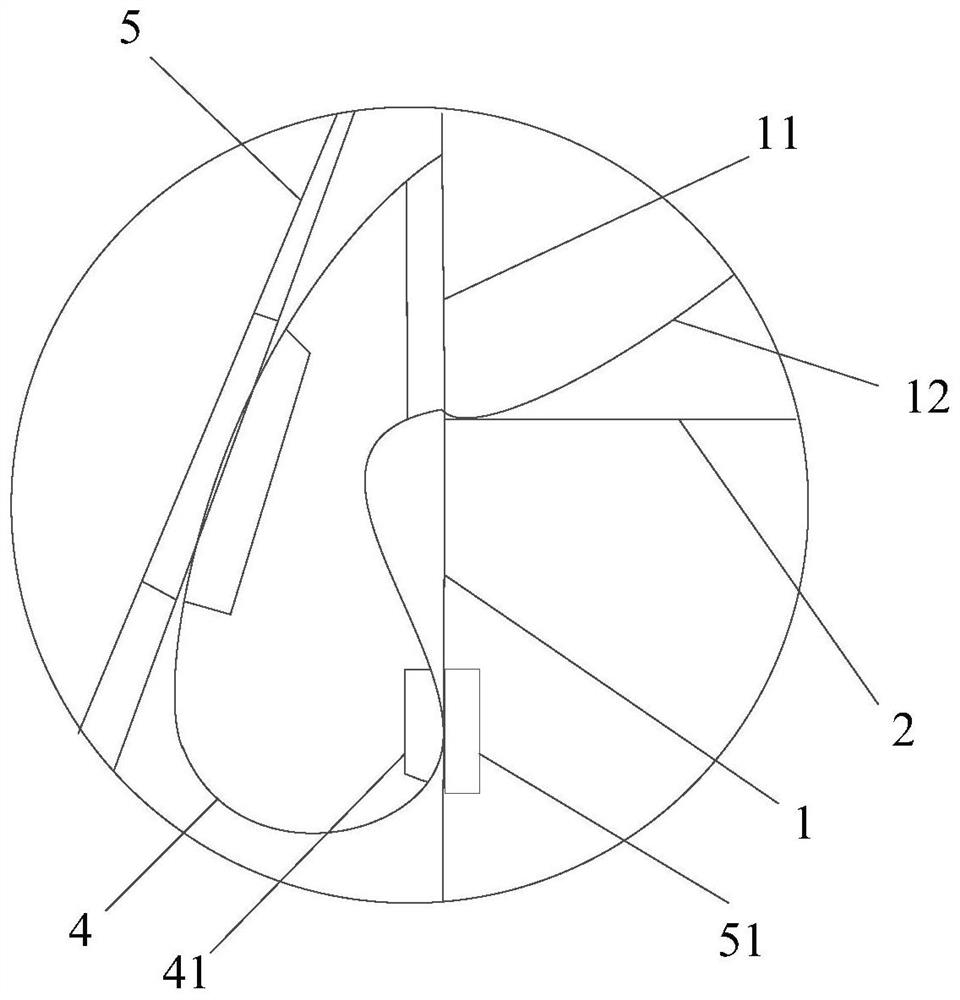

[0036] This embodiment provides a sampling device for periodic detection of microorganisms, including an injection tube 1, the head end of the injection tube 1 is connected with a detachable needle 2, and the injection tube 1 is made of a steel pipe, a ceramic tube or a transparent glass tube. The needle 2 is used for direct contact with the microbial sample liquid. There is a push rod 3 inside the injection tube 1. Push the push rod 3 in the direction of the needle 2 to discharge the air in the injection tube 1, and then pull the push rod 3 to the outside of the injection tube 1. , the microbial sample liquid enters the interior of the injection tube 1, and the side wall of the injection tube 1 is provided with a liquid separation hole 11 at 1-4 cm from the tail end of the needle 2, and a sampling bag 4 is detachably connected to the liquid separation hole 11. 4 is located outside the injection tube 1, and the outside of the injection tube 1 is provided with a extrusion assemb...

Embodiment 2

[0044] A sampling device for periodic detection of microorganisms, basically the same structure as in Example 1, the difference is that see Figure 5 , in order to reduce the work of cleaning the instrument and improve the utilization rate of the instrument, the present invention also includes a head end installation sleeve 9 and a tail end installation sleeve 91. Externally, one end of the pressure plate 5 is rotatably connected to the head-end mounting sleeve 9 instead of being mounted on the injection tube 1, the tail-end mounting sleeve 91 is sleeved and clamped on the tail end of the push rod 3, and the other end of the pressure plate 5 is rotatably connected to the The tail end is installed on the sleeve 91, but not on the push rod 3. Before sampling, install the head end installation sleeve 9 and the tail end installation sleeve 91 according to Figure 5 The shown structure is installed in the corresponding position, and then samples are taken according to the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com