Roll-to-roll continuous coating equipment for vacuum evaporation of liquid raw materials

A liquid raw material, vacuum evaporation technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating and other directions, can solve the problems of expensive raw materials, uneven spraying, high cost, and achieve stable product quality and process repeatability Excellent, high equipment stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

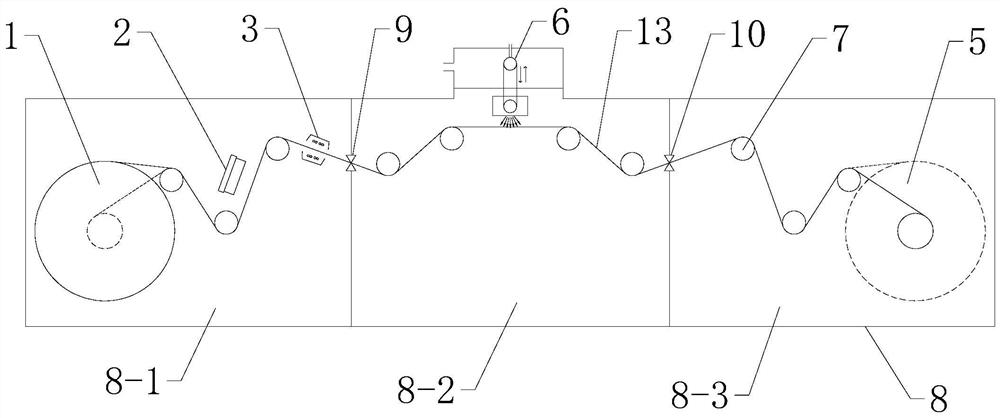

[0033] Such as figure 1 As shown, a roll-to-roll continuous coating equipment for vacuum evaporation of liquid raw materials, including a vacuum chamber, in which an unwinding mechanism, a coating mechanism, and a winding mechanism are sequentially arranged along the running path of the substrate, and the unwinding mechanism includes an unwinding roller , the winding mechanism includes a winding roller, the coating mechanism includes a liquid raw material evaporation device, and an ion cleaning device, a heater and a plurality of guide rollers are also arranged on the path of the substrate, and the substrate coming out of the unwinding roller passes through multiple A guide roller, a winding roller, the ion cleaning device is used to ion clean the substrate, the heater is used to heat the substrate, and the spraying direction of the liquid raw material evaporation device faces the substrate.

[0034] Such as figure 1 As shown, the vacuum chamber includes an unwinding chamber,...

Embodiment 2

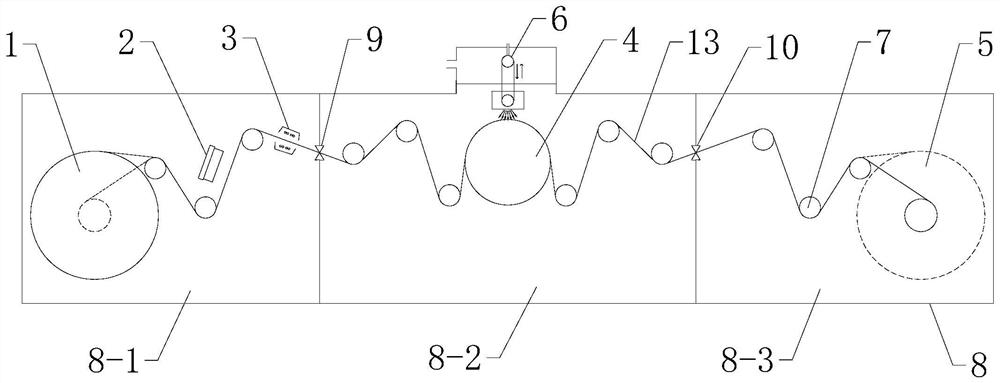

[0044] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the coating mechanism further includes a first coating roller, and the liquid raw material evaporation device is located at the first coating roller. The substrate coming out of the unwinding roller passes through the first diaphragm valve, the first coating roller, the second diaphragm valve, and the winding roller in sequence. During the operation of the substrate, the substrate is also guided by multiple guide rollers, and the liquid raw material The evaporating device coats the substrate on the first coating roller.

Embodiment 3

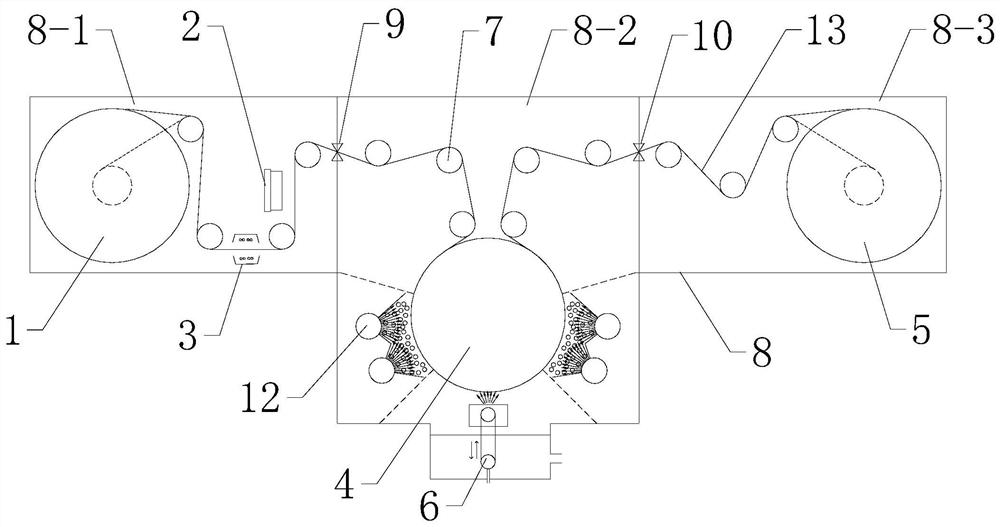

[0046] Such as image 3 As shown, the difference between this embodiment and the second embodiment is that, in this embodiment, a coating source is also provided at the first coating roller. The coating source is magnetron sputtering cathode, evaporation source, arc source or PECVD source. Metal film, dielectric film and other film layers can be plated through the coating source, and the hydrophobic and oil-repellent film and other film layers can be continuously plated on the substrate, which is convenient for coating multi-layer films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com