Heat-preservation and cold-proof waterborne clothing leather and preparation method thereof

A kind of clothing leather and water-based technology, which is applied in the direction of textiles and paper making, can solve the problems of poor wearing comfort, coldness, water vapor is not easy to volatilize, etc., and achieve the effect of compactness and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

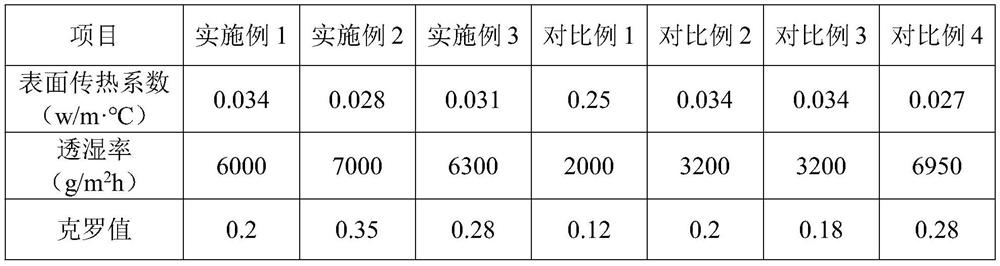

Examples

Embodiment 1

[0029] S1. Select anionic water-based polyurethane with a solid content of 30wt%, a 100% modulus of 60MPa, and add 30 parts of hollow microsphere filler, 0.1 part of defoamer, 0.3 part of wetting agent, and 0.1 part of thickener in every 100 parts of water-based polyurethane agent to prepare hollow microsphere water-based polyurethane fabric;

[0030] S2, choose solid content to be 40wt% anionic water-based polyurethane, add polymerization degree in every 100 parts of anionic water-based polyurethane to be 3 parts of PVA resin, 2 parts of ethylene glycol dicarboxylate, 1 part of blowing agent, disperse evenly, Prepare the water vapor absorbing layer slurry;

[0031] S3, choosing the water-based polyurethane with a solid content of 30wt% as a film-forming substance, adding 0.3 part of defoamer, 1 part of wetting agent, 0.6 part of thickener and 30 parts of far-infrared ceramic powder in every 100 parts of water-based polyurethane, obtained Bottom adhesive layer slurry;

[003...

Embodiment 2

[0036] S1. Select anionic water-based polyurethane with a solid content of 30wt%, 100% modulus of 60MPa, and add 70 parts of hollow microsphere filler, 0.2 part of defoamer, 1 part of wetting agent, and 0.5 part of thickener to every 100 parts of water-based polyurethane agent to prepare hollow microsphere water-based polyurethane fabric;

[0037] S2, choose solid content to be 50wt% anionic water-based polyurethane, every 100 parts of anionic water-based polyurethanes, adding polymerization degree is 6 parts of PVA resins of 1700, 4 parts of ethylene glycol dicarboxylates, 3 parts of foaming agents, disperse evenly, Prepare the water vapor absorbing layer slurry;

[0038] S3, choosing the water-based polyurethane with a solid content of 30wt% as a film-forming substance, adding 0.3 part of defoamer, 1 part of wetting agent, 0.6 part of thickener and 30 parts of far-infrared ceramic powder in every 100 parts of water-based polyurethane, obtained Bottom adhesive layer slurry; ...

Embodiment 3

[0043] S1. Select anionic water-based polyurethane with a solid content of 30wt%, a 100% modulus of 60MPa, and add 50 parts of hollow microsphere filler, 0.2 parts of defoamer, 1.5 parts of wetting agent, and 0.3 parts of thickener to every 100 parts of water-based polyurethane agent to prepare hollow microsphere water-based polyurethane fabric;

[0044] S2, choose solid content to be 45wt% anionic water-based polyurethane, every 100 parts of anionic water-based polyurethanes, adding polymerization degree is 5 parts of PVA resin, 3 parts of ethylene glycol dicarboxylates, 2 parts of blowing agent in the anionic water-based polyurethane, disperse evenly, Prepare the water vapor absorbing layer slurry;

[0045] S3, choosing the water-based polyurethane with a solid content of 30wt% as a film-forming substance, adding 0.3 part of defoamer, 1 part of wetting agent, 0.6 part of thickener and 30 parts of far-infrared ceramic powder in every 100 parts of water-based polyurethane, obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com