A method for measuring electron energy distribution curve at collector inlet of traveling wave tube

A technology of electron energy and distribution curve, which is applied in the direction of vacuum tube testing, etc., can solve the problems of long design cycle for collector efficiency improvement, high design cost, and constraints on traveling wave tubes, so as to reduce the number of iterative development times and design cycle, and reduce development costs , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

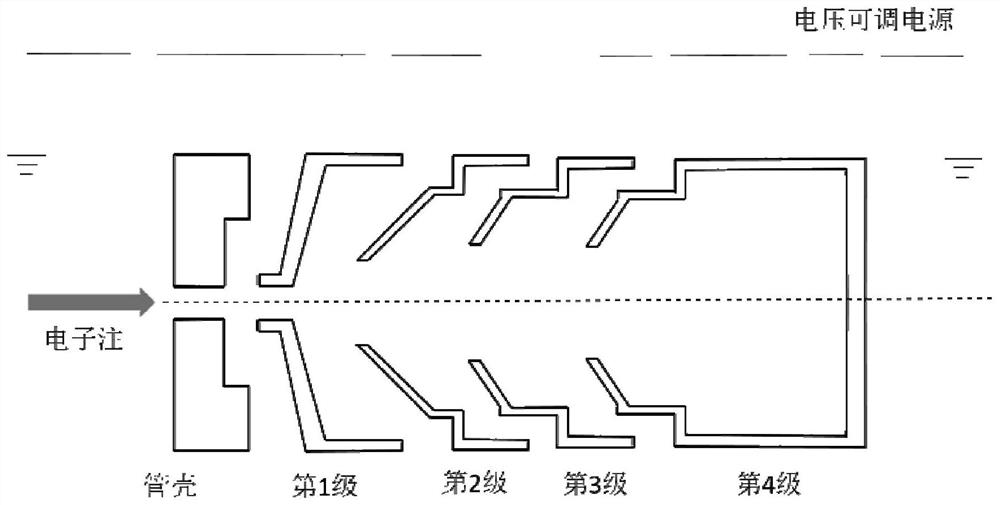

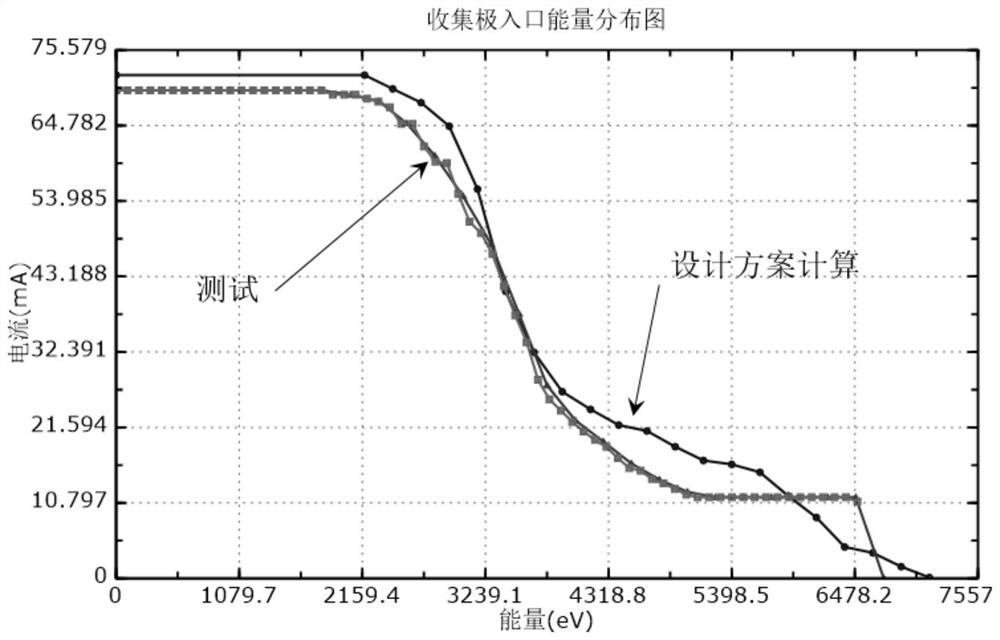

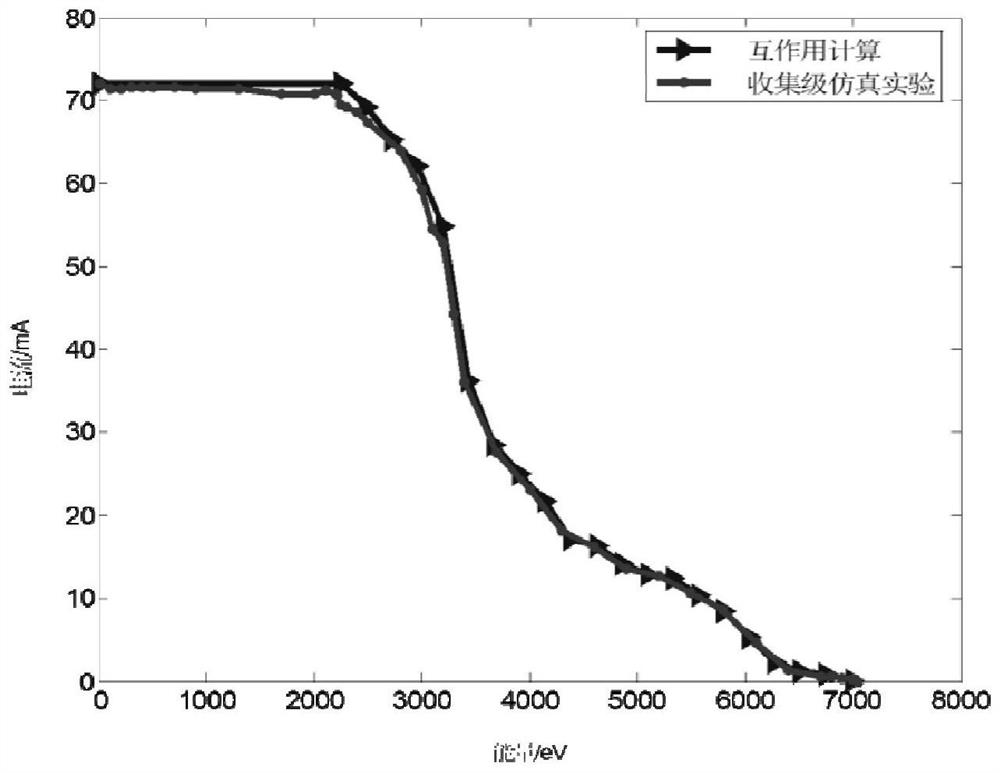

[0032] The present invention will be further described in detail below in conjunction with a space traveling wave tube four-stage step-down collector.

[0033] Step 1 Description:

[0034] Connect the traveling wave tube power supply, the input signal input device and the output signal receiving device, set the working ratio of the traveling wave tube electron injection modulation power supply to 1%-5%, and set the traveling wave tube spiral flow safety threshold I h , given the recovery current indication value I of the stop voltage step-down sweep R .

[0035] For the measurement data of the traveling wave tube, the first step is to add power to the traveling wave tube and input signal input device and output signal receiving device. Make sure the TWT is working properly. In order to ensure safety, the TWT electronic injection modulation power supply is tested from a low duty ratio, and the duty ratio range of 1%-5% is selected here; the initial duty ratio is set to 5% in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com