Power module thermal impedance modeling method based on Fourier analysis spread angle

A technology for power modules and modeling methods, applied in special data processing applications, computer-aided design, design optimization/simulation, etc. Accuracy and versatility, accurate description, the effect of improving computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

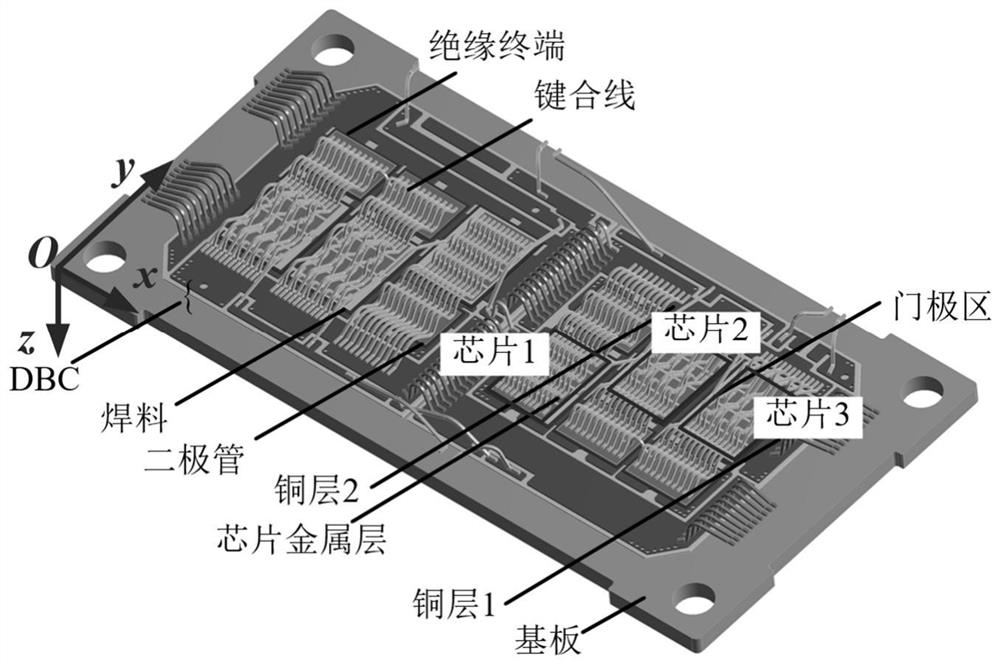

[0036] In order to explain the present invention in more detail, the present invention will be further described in detail below in conjunction with the accompanying drawings, taking the SEMiKron power semiconductor module SEMiX603GB12E4p as an example.

[0037] The present invention proposes a power module thermal impedance modeling method based on Fourier analytical diffusion angle, which specifically includes the following steps:

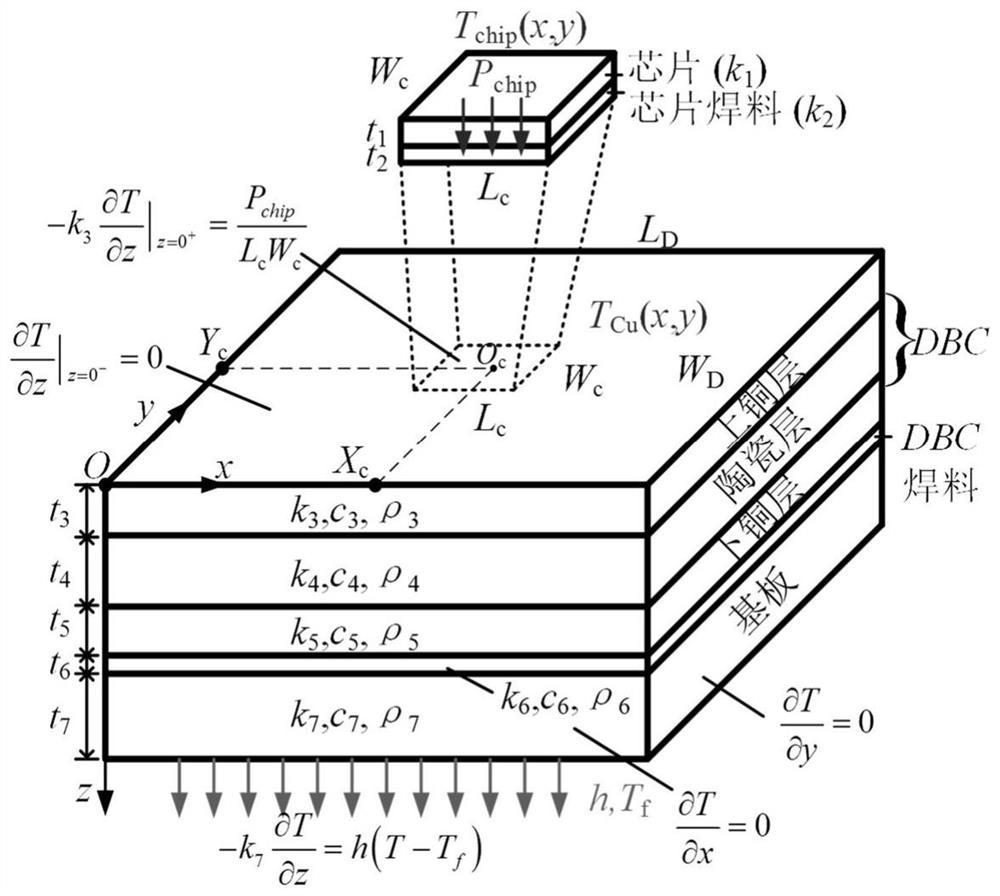

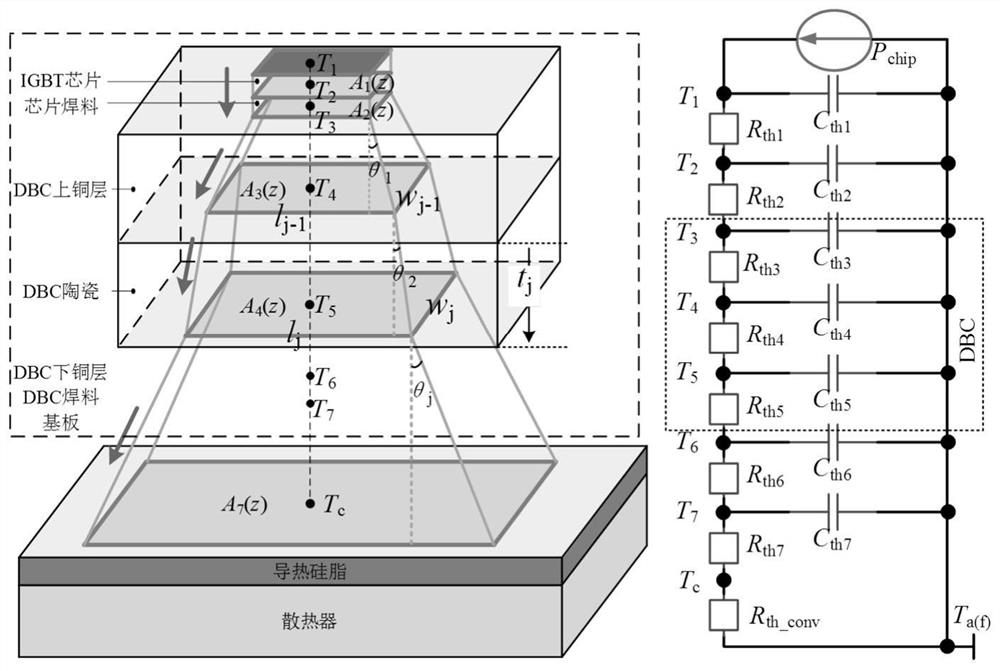

[0038] S1. Write the Fourier series expression of the vertical axis heat flux of each layer in the power module with undetermined coefficients;

[0039] S2. Based on the material parameters and boundary conditions, combined with the heat diffusion function between the inner layers of the power module, recursively solve the undetermined coefficients of the Fourier series expression of the vertical axis heat flux of each layer;

[0040] S3. Based on the size parameters and chip position coordinates, based on the Fourier series expression of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com