Lamination production line system of battery pole pieces

A battery pole piece and production line technology, applied in the field of battery pole piece lamination production line system, can solve the problems of production equipment stop working, high maintenance cost, low use flexibility, etc., so as to reduce equipment cost, reduce maintenance cost, use Highly flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

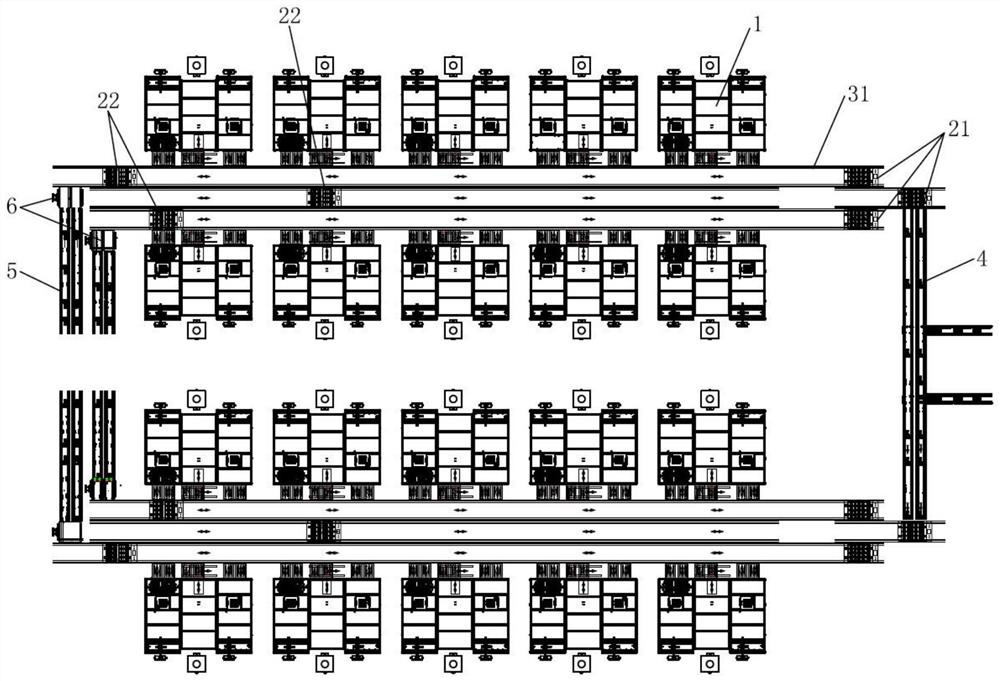

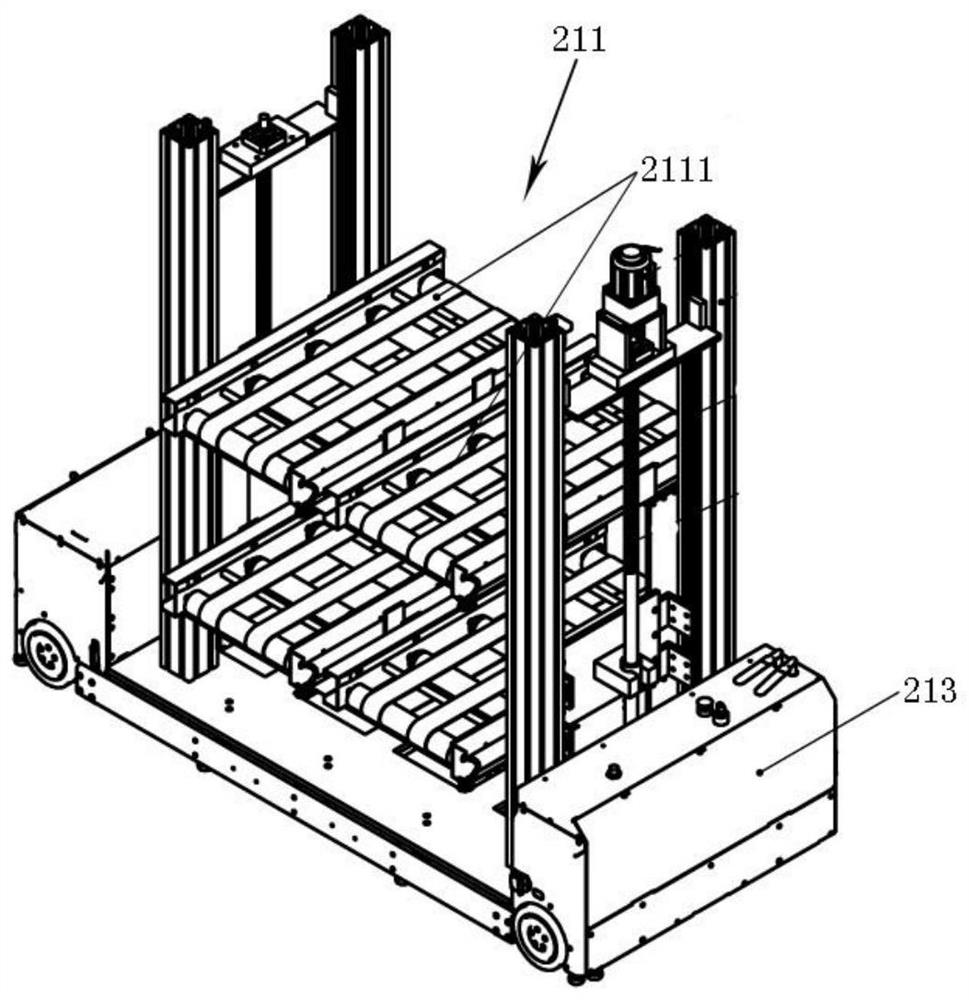

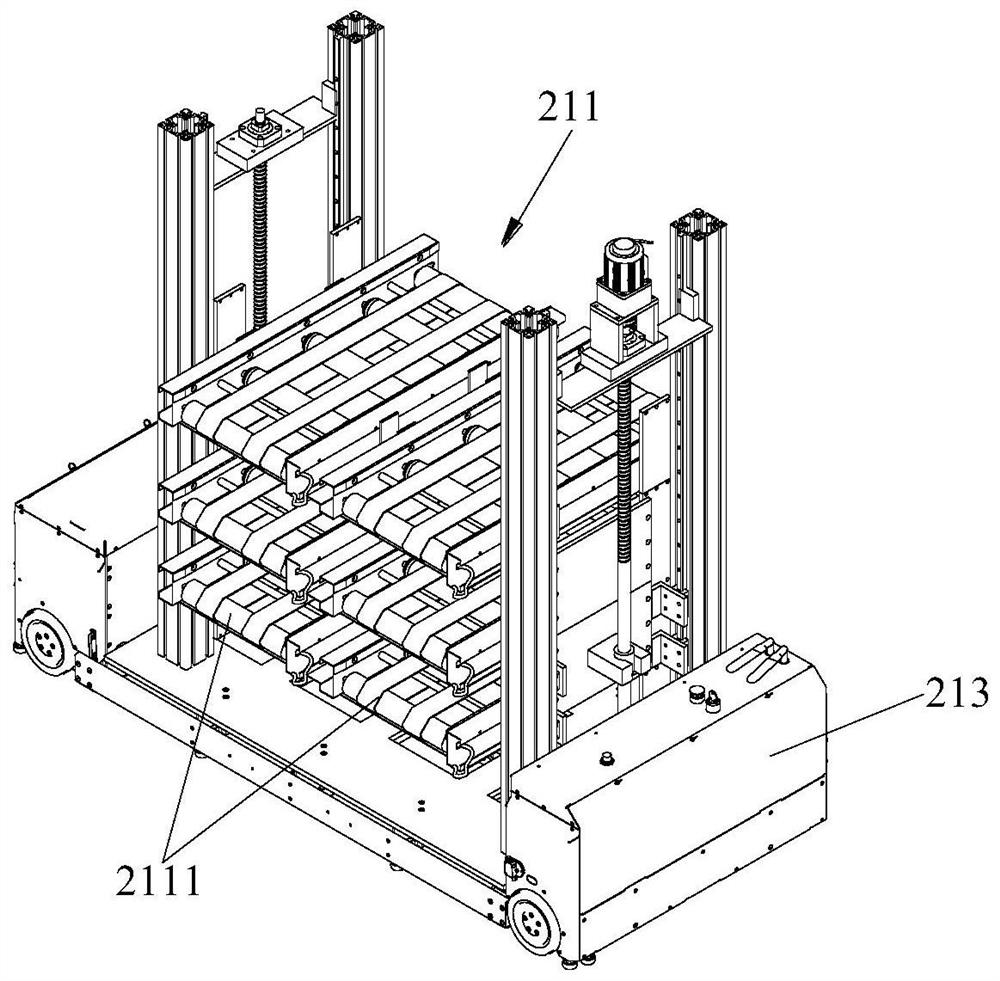

[0038] Such as figure 1 As shown, the stacking production line system of battery pole pieces provided in this embodiment includes a conveying track, a stacking machine 1 and a shuttle car. There are multiple stacking machines 1, and the stacking machines 1 are arranged on the side of the transporting track. A stacking machine 1 is distributed along the length direction of the conveying track. The shuttle car can run on the conveying track, and the shuttle car can transport the pole piece to the material inlet of the stacker 1 and / or the finished battery cell at the output port of the stacker 1 to a designated location.

[0039] A shuttle car is arranged on the conveying track, and a plurality of stacking machines 1 are distributed along the length direction of the conveying track. The shuttle car can transport the pole piece and / or the finished battery cell, which replaces the jacking and transferring mechanism in the prior art, and does not require every Each lamination mach...

Embodiment 2

[0060] Such as Figure 5 As shown, the stacking production line system of battery pole pieces provided in this embodiment includes a conveying track, a stacking machine 1 and a shuttle car. There are multiple stacking machines 1, and the stacking machines 1 are arranged on the side of the transporting track. A stacking machine 1 is distributed along the length direction of the conveying track. The shuttle car can run on the conveying track, and the shuttle car can transport the pole piece to the material inlet of the stacker 1 and / or the finished battery cell at the output port of the stacker 1 to a designated location.

[0061] A shuttle car is arranged on the conveying track, and a plurality of stacking machines 1 are distributed along the length direction of the conveying track. The shuttle car can transport the pole piece and / or the finished battery cell, replacing the jacking and transferring mechanism in the prior art, without the need for each Each stacker 1 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com