Multifunctional ash removal equipment for coal ash warehouse

A multi-functional, fly ash technology, used in cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low ash cleaning efficiency, inability to achieve automatic ash cleaning, etc., and achieves a large working range and rigidity. Large, high-precision control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

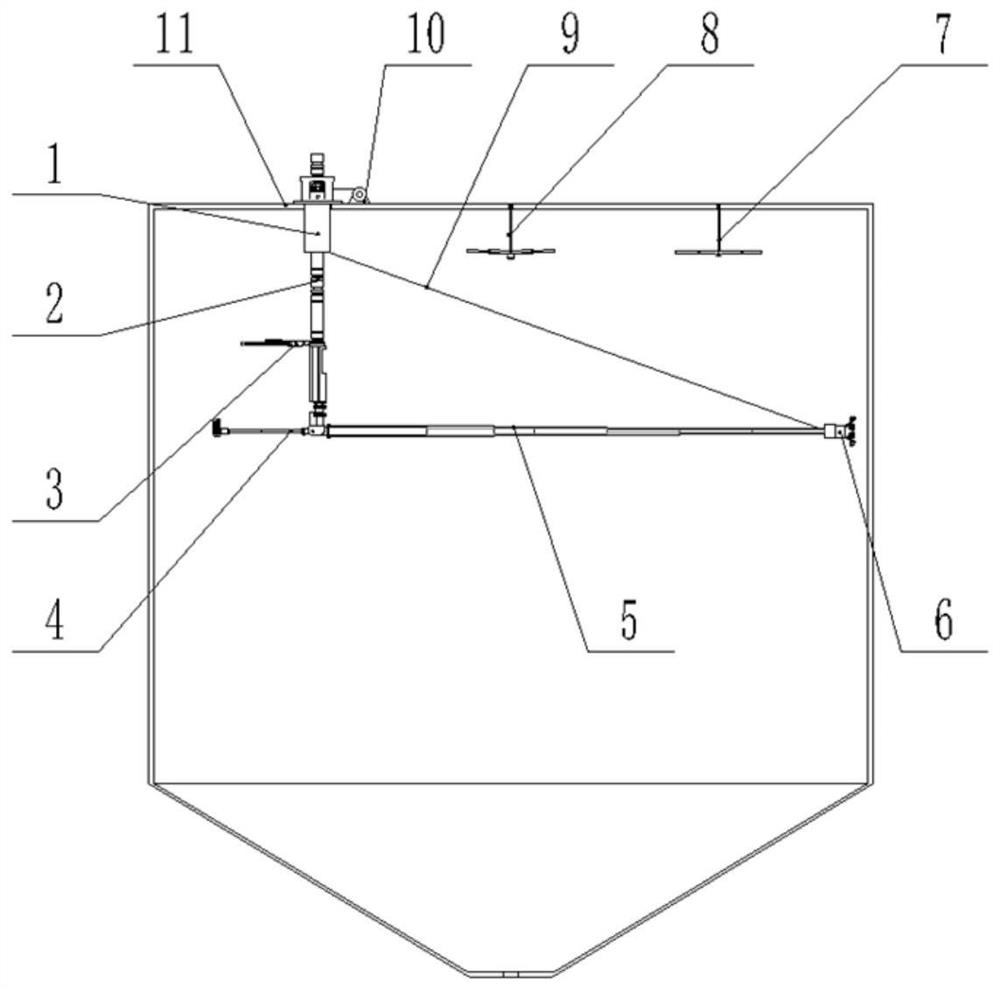

[0070] A kind of fly ash multifunctional dust removal device of the present invention (abbreviation dust removal device, such as figure 1 shown), including a clamping module 1 (composed of a clamping mechanism and a clamping mechanism), an auxiliary bracket 3, a secondary cantilever 4, a high-rigidity mechanical telescopic arm 5, a flexible cleaning robot 6, and a sensory monitoring device, etc., which are mainly used for Clean up the inner wall of the fly ash storehouse 11.

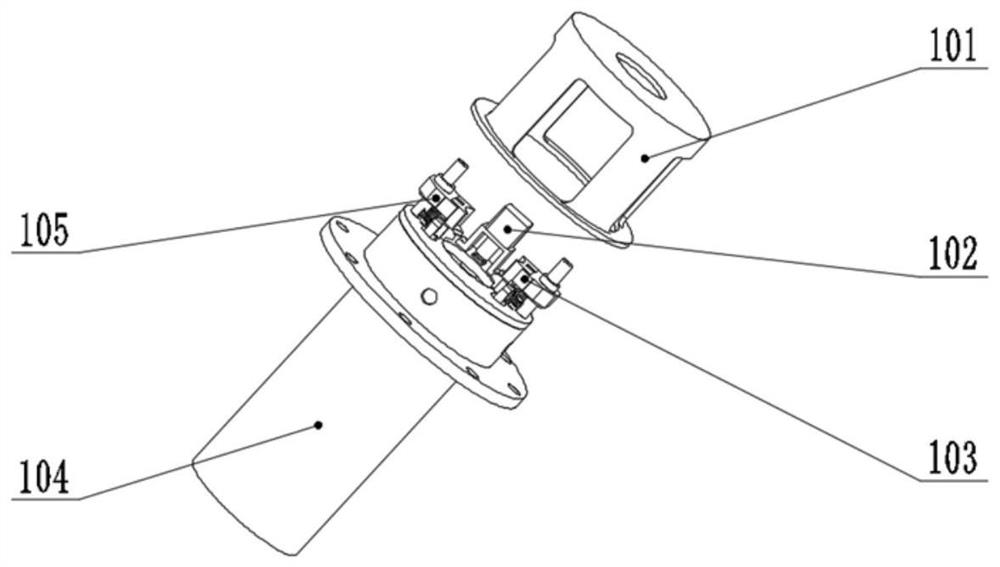

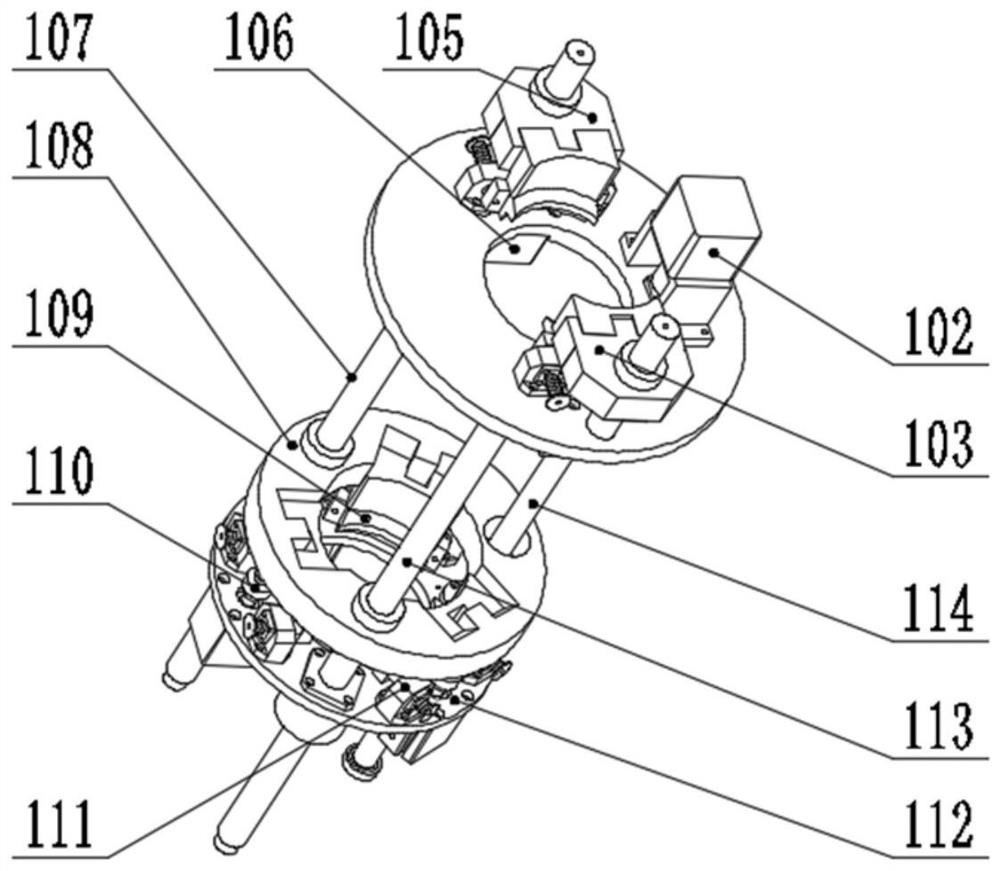

[0071] The structure of the clamping mechanism is as figure 2 As shown, it includes a lifting link guide part 101, a servo feed motor 102, an outer oblique slider 103, an entrance fixing device 104, and an outer oblique slider holder 105; the structure of the holding mechanism is as follows image 3 As shown, it includes a clamping motor 106, a first guide light rod 107, an inner inclined block holder 108, an inner inclined slide block 109, an inner fixed cylinder 110, an inclined slide block feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com