A kind of polishing process of indium phosphide substrate

An indium phosphide and substrate technology, which is applied in the field of indium phosphide polishing, can solve the problems of high environmental requirements, unsatisfactory polishing uniformity, unstable polishing effect and the like, and achieves the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

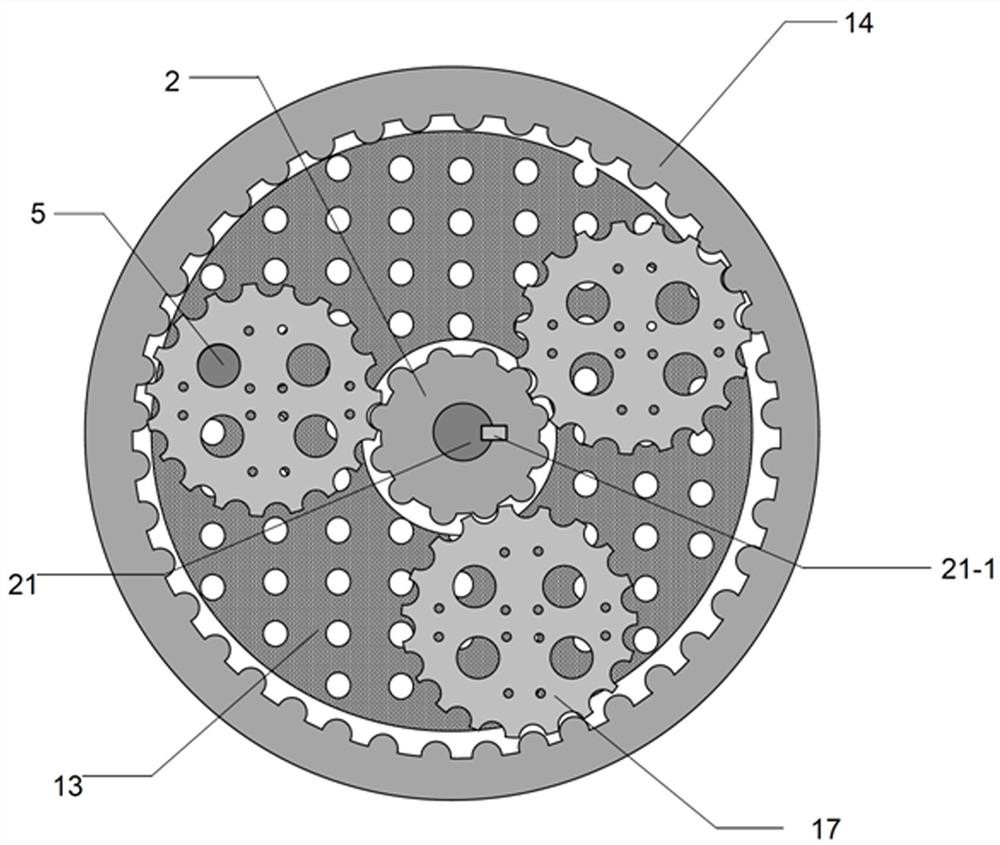

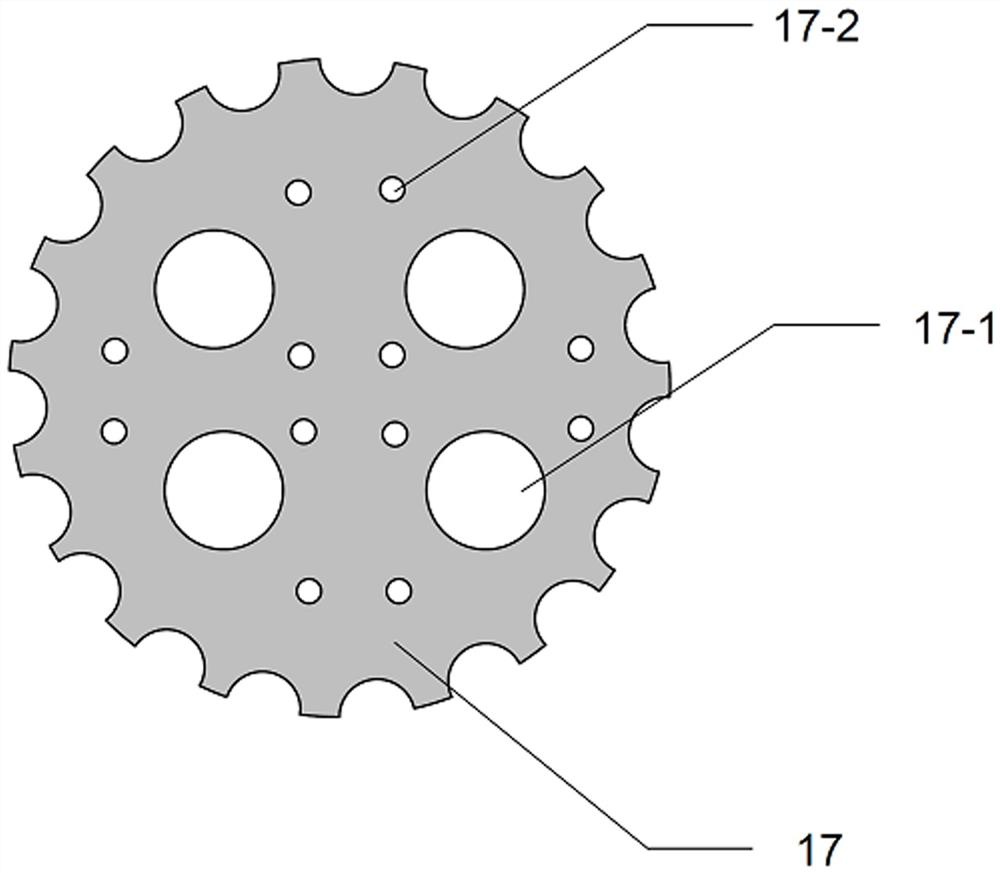

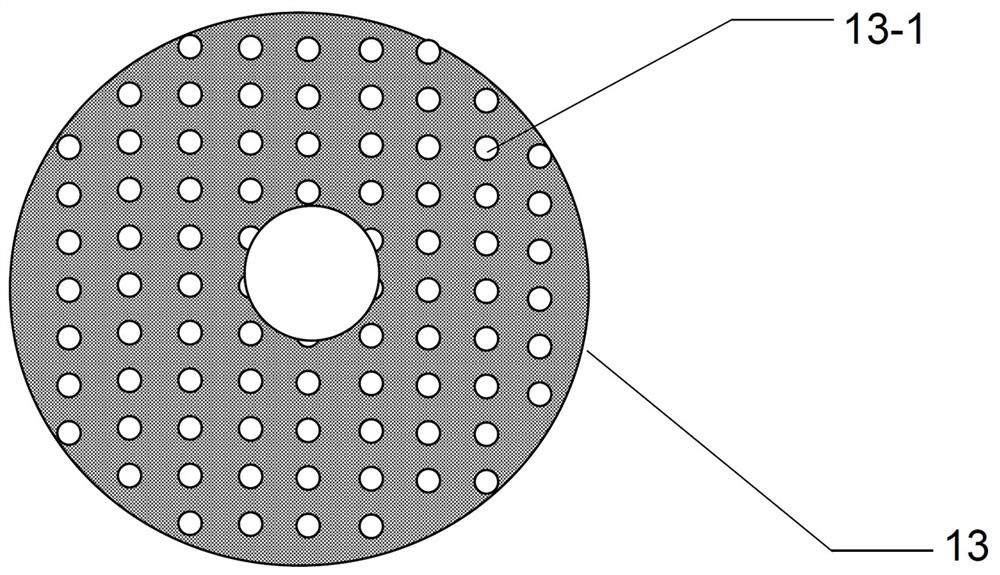

[0028] Take figure 1 , The polishing apparatus of the indium phosphide of the present invention includes an electrolytic cell 3, and the anode disk support rod 8 is positioned at the bottom of the bottom of the electrolytic cell 3 by the anode elevator mechanism, which is hinged on the upper end of the anode disk support rod 8, by means of a cathode. The lifting mechanism is positioned on the cathode disk support rod 16 above the anode disk 7, and is disposed at the cathode disk 1 at the lower end of the cathode disk support rod 16, by means of the cathode polishing cloth 6, the polishing cloth 13 at the lower end surface of the cathode disk 1, by means of the connecting mechanism The graphite electrode plate 9 is disposed on the anode disk 7, and the intermediate drive mechanism is disposed on the end face of the graphite electrode plate 9, and is positioned in the graphite electrode plate 9 and the star meter 17 by means of anode polishing cloth. The polishing cloth 13, the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com