Method for efficiently preparing raw material medicine icodextrin

A technology for testing dextrin and raw materials, which is applied in the field of high-efficiency preparation of raw material icodextrin, which can solve problems such as complex process, high cost, and unsuitability for industrial production, and achieve optimized ultrafiltration process, mild reaction, and reduction of insoluble starch particles the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

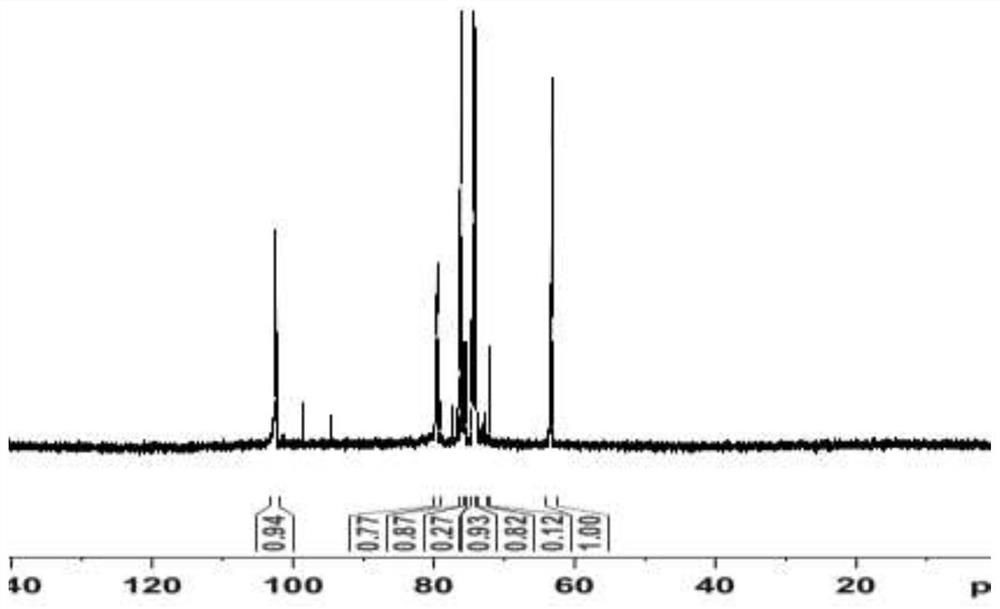

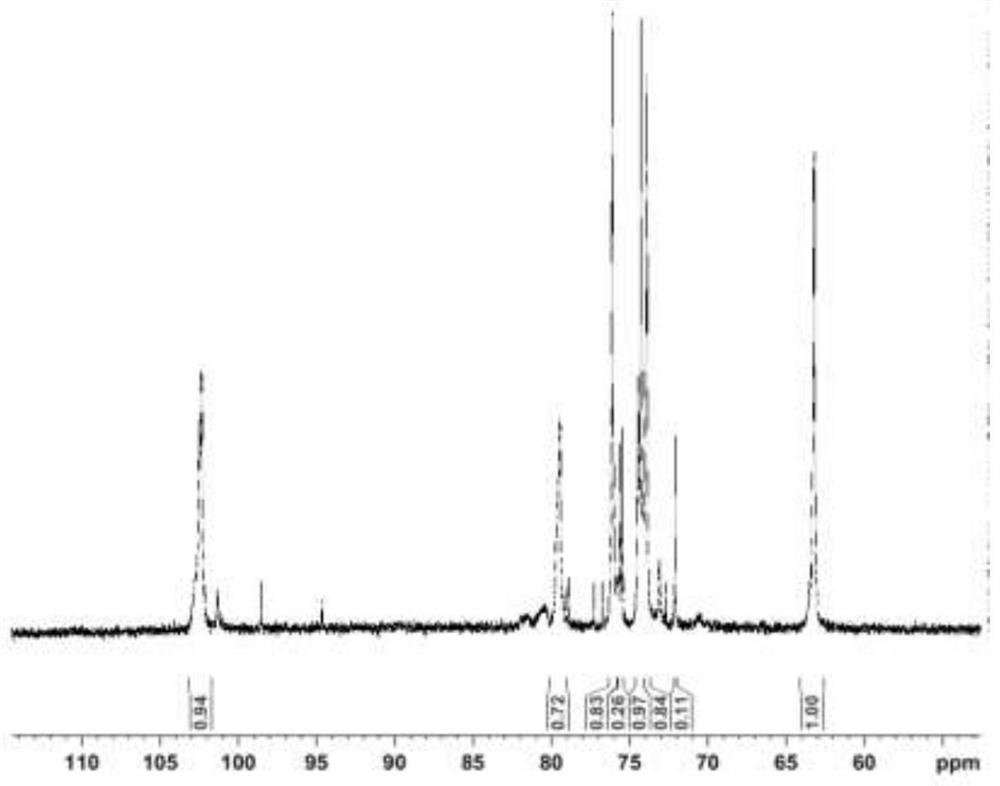

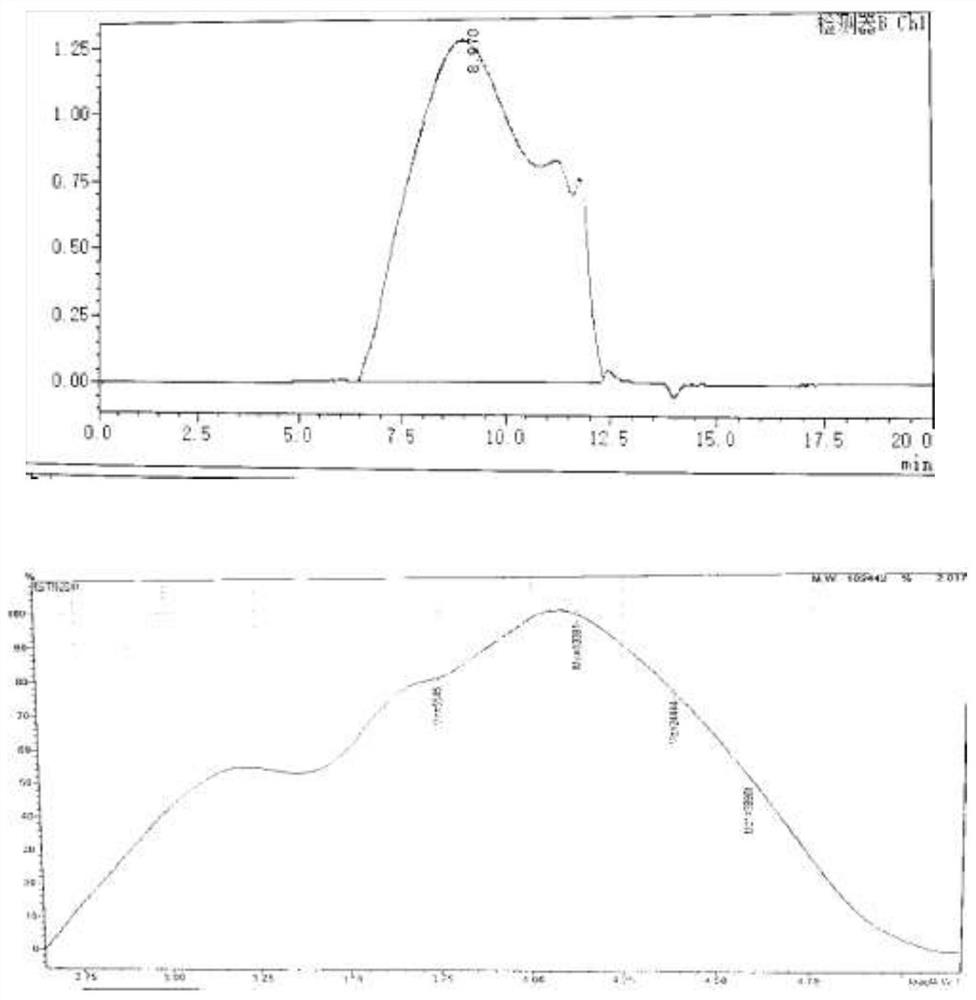

Image

Examples

Embodiment 1

[0039] 1) Sizing and liquefaction: mix 100g of starch, 300g of water and 1-2g of polystyrene microspheres at room temperature for slurrying, place in a water bath at 100°C and stir for gelatinization for 20 minutes;

[0040] 2) Lower the gelatinized starch to 90°C, slowly drop 100g of hydrochloric acid solution with a mass concentration of 0.27% into the reaction solution, and control the dropwise addition within 30min; heat preservation reaction for 2h;

[0041] 3) Adjust the pH to between 3 and 4, terminate the reaction, add 0.3g of activated carbon and 0.015g of chitosan to decolorize at room temperature, use 100KDa and 5000Da ultrafiltration membranes for molecular weight screening respectively, and control the ultrafiltration pressure to 300KPa, 5000Da for ultrafiltration When the polarimeter tracks the value of the optical rotation of the discharged liquid to 0.200, the ultrafiltration is completed, and the liquid is spray-dried to obtain the finished product. Yield 67.4...

Embodiment 2

[0044] 1) Sizing and liquefaction: Mix 100g of starch, 800g of water and 1-2g of insoluble cellulose particles at room temperature for slurrying, place in a water bath at 95°C and stir for 30 minutes to gelatinize.

[0045] 2) Control the gelatinized starch at 95°C, slowly drop 100 g of nitric acid solution with a mass concentration of 0.4% into the reaction solution, and control the dropping within 40 minutes; keep warm for 3 hours;

[0046] 3) Adjust the pH to between 3 and 4, terminate the reaction, add 0.55g of activated carbon, 0.033g of chitosan to decolorize at room temperature, use 100KDa and 5000Da ultrafiltration membranes for molecular weight screening, ultrafiltration pressure 300KPa, 5000Da ultrafiltration process with optical rotation The ultrafiltration is completed when the optical rotation value of the effluent liquid is tracked by the instrument to 0.350, and the material liquid is spray-dried to obtain the finished product. Yield 68.2% (starch dry product).

...

Embodiment 3

[0049] 1) Sizing and liquefaction: Mix 100g of starch, 200g of water and 1-2g of poly(N-isopropylacrylamide) microgel particles at room temperature for slurrying, place in a 95°C water bath and stir for gelatinization for 50min;

[0050] 2) Lower the gelatinized starch to 85°C, slowly drop 100 g of sulfuric acid solution with a mass concentration of 0.4% into the reaction solution, and control the addition within 30 minutes; heat preservation reaction for 2.5 hours;

[0051] 3) Adjust the pH to between 3 and 4, terminate the reaction, add 0.36g of activated carbon, 0.025g of chitosan to decolorize at room temperature, use 100KDa and 5000Da ultrafiltration membranes for molecular weight screening, ultrafiltration pressure 400KPa, 5000Da ultrafiltration process with optical rotation The ultrafiltration is completed when the optical rotation value of the effluent liquid is tracked by the instrument to 0.250, and the material liquid is spray-dried to obtain the finished product. Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com