Super wear-resistant rubber, preparation method and crawler belt

A super wear-resistant, production method technology, applied in the preparation method and track, super wear-resistant rubber field, can solve the problems of short life, etc., to achieve the effect of prolonging the service life, improving the wear resistance of rubber, and fully vulcanized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

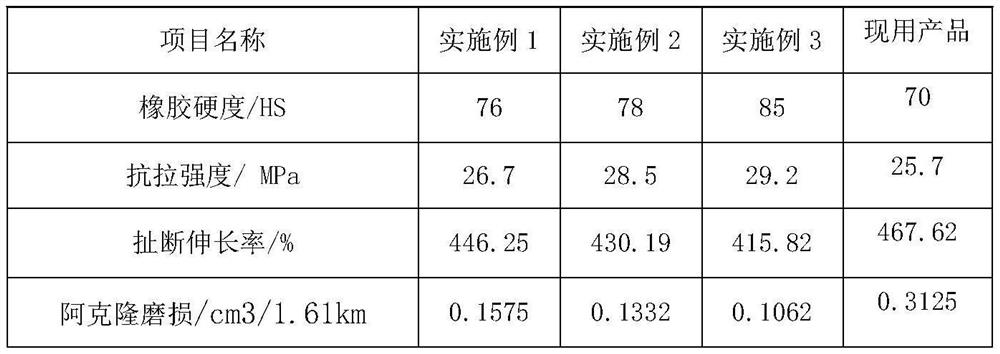

Examples

Embodiment 1

[0047] The super wear-resistant rubber of this embodiment comprises: raw rubber is made up of 70 parts of natural rubber and 30 parts of styrene-butadiene rubber; vulcanization accelerator is 2 parts of TMTD; 3 parts of magnesium oxide; 4 parts of zinc oxide; 1 part of stearic acid; antioxidant RD2 40 parts of carbon black N220; 20 parts of surface modified nano-diamond; 1 part of graphene; 1.5 parts of antiscorch agent CTP; 1 part of light stabilizer PDS; portion composition.

[0048] Adopt present embodiment raw material to operate rubber product according to the following sequence:

[0049] Preparation of ingredients: Zinc oxide, magnesium oxide, anti-aging agents RD, AW, anti-scorch agent CTP, stearic acid are pulverized and dried, then sieved, weighed in proportion and stirred evenly to form mixture A1;

[0050] Mastication: Adjust the speed ratio of the front and rear rollers of the open mill to 1:1.3, adjust the roller distance of the open mill to 1mm, add natural rubb...

Embodiment 2

[0054] The raw materials of this embodiment include: raw rubber consisting of 60 parts of natural rubber and 40 parts of butadiene rubber; vulcanization accelerator consisting of 2 parts of sulfur powder and TMTD; 2 parts of magnesium oxide, 2 parts of zinc oxide, 1.5 parts of stearic acid, The anti-aging agent is composed of 2.5 parts each of NMB and DFC-34; 30 parts of carbon black N121, 30 parts of surface-modified nano-diamond, 2 parts of graphene, 1 part of anti-scorch agent CTP, 1 part of light stabilizer PDS, and flame retardant. Composed of 1 part each of antimony oxide and chlorinated paraffin.

[0055] The corresponding preparation method is as follows:

[0056] Preparation of ingredients: Zinc oxide, magnesium oxide, anti-aging agent NMB, DFC-34, anti-scorch agent CTP, stearic acid are pulverized and dried, then sieved, weighed in proportion and stirred evenly to form mixture A2;

[0057] Mastication: adjust the speed ratio of the front and rear rollers of the open...

Embodiment 3

[0061] The super wear-resistant rubber of this embodiment comprises: raw rubber is made up of 50 parts of natural rubber, 30 parts of styrene-butadiene rubber, and 20 parts of butadiene rubber, and the vulcanization accelerator is made up of sulfur powder, DCP and TMTD respectively; 3 parts of zinc oxide, 2 parts of stearic acid, anti-aging agent consisting of 2 parts of RD, AW and NMB, 40 parts of carbon black N330, 20 parts of surface modified nano-diamond, 4 parts of graphene, 2 parts of anti-scorch agent CTP 2 parts, light stabilizer PDS 2 parts, flame retardant consists of antimony trioxide, chlorinated paraffin each 1.5 parts.

[0062] The corresponding preparation method operates in the following order:

[0063] Preparation of ingredients: Zinc oxide, magnesium oxide, anti-aging agents RD, AW, NMB, anti-scorch agent CTP, stearic acid are pulverized and dried, then sieved, weighed in proportion and stirred evenly to form mixture A3;

[0064] Mastication: adjust the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com