Micro-emulsified diesel oil product and production process thereof

A production process and micro-emulsion technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of further improvement of fuel performance, high diesel energy density, low fuel consumption rate, etc., to ensure quality and reduce reaction. time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

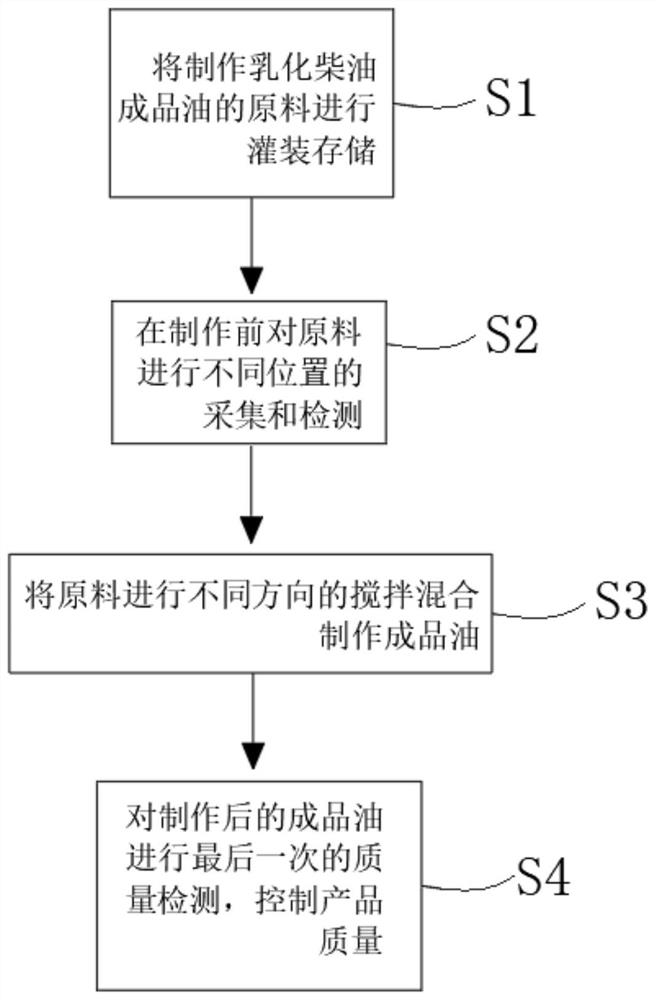

Method used

Image

Examples

Embodiment 1

[0028] A kind of microemulsion diesel product oil, by concentration percentage, comprises:

[0029] Diesel 75%

[0030] water 15%

[0031] Micro-emulsion diesel emulsification aid 1%.

Embodiment 2

[0033] A kind of microemulsion diesel product oil, by concentration percentage, comprises:

[0034] Diesel 80%

[0035] Water 17%

[0036] Micro-emulsion diesel emulsification aid 2%.

Embodiment 3

[0038] A kind of microemulsion diesel product oil, by concentration percentage, comprises:

[0039] Diesel 85%

[0040] water 20%

[0041] Micro-emulsion diesel emulsification aid 3%.

[0042] Example 1

[0043] S1: First prepare the raw materials required for the production of emulsified diesel oil, and inject the prepared diesel oil, water and micro-emulsified diesel emulsification aid into the corresponding storage tank for storage, and the producer strictly controls the storage temperature of the raw materials at 20 degrees Celsius;

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com