A method of electroplating conductive material on a semiconductor wafer

A semiconductor and conductive coating technology, applied in semiconductor devices, circuits, sputtering and other directions, can solve the problem of uneven thickness of the coating, and achieve the effect of fast preparation, not easy to crack, and high processing ability index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

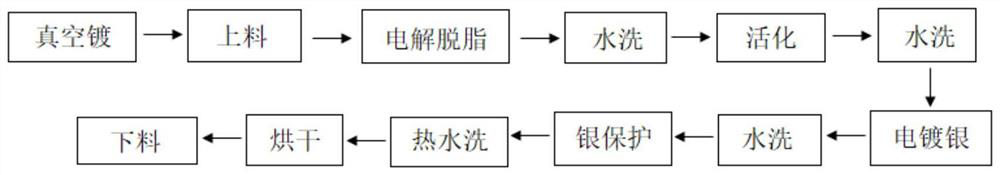

[0043] A method for electroplating conductive material on a semiconductor wafer, comprising the following steps:

[0044] 1) Fix the cleaned wafer in the inner chamber, and then place the three materials of titanium, nickel and silver with a purity of more than 99.99% respectively in three acupuncture points on the rotating workpiece disk of the evaporation table;

[0045] 2) Close and seal the inner chamber, and then start the vacuum system to evacuate the inner chamber to 1.0×10 -4 Pa;

[0046] 3) First put the acupuncture point containing the titanium material at the working position, start the evaporation source and power on, adjust the current to 100A, open the baffle to start evaporation, the titanium material is heated to the boiling point and evaporated, depositing a layer of titanium on the surface of the wafer coating, when the preset thickness is reached, switch the acupuncture point on the evaporation source, use the same operation and sequentially vapor-deposit n...

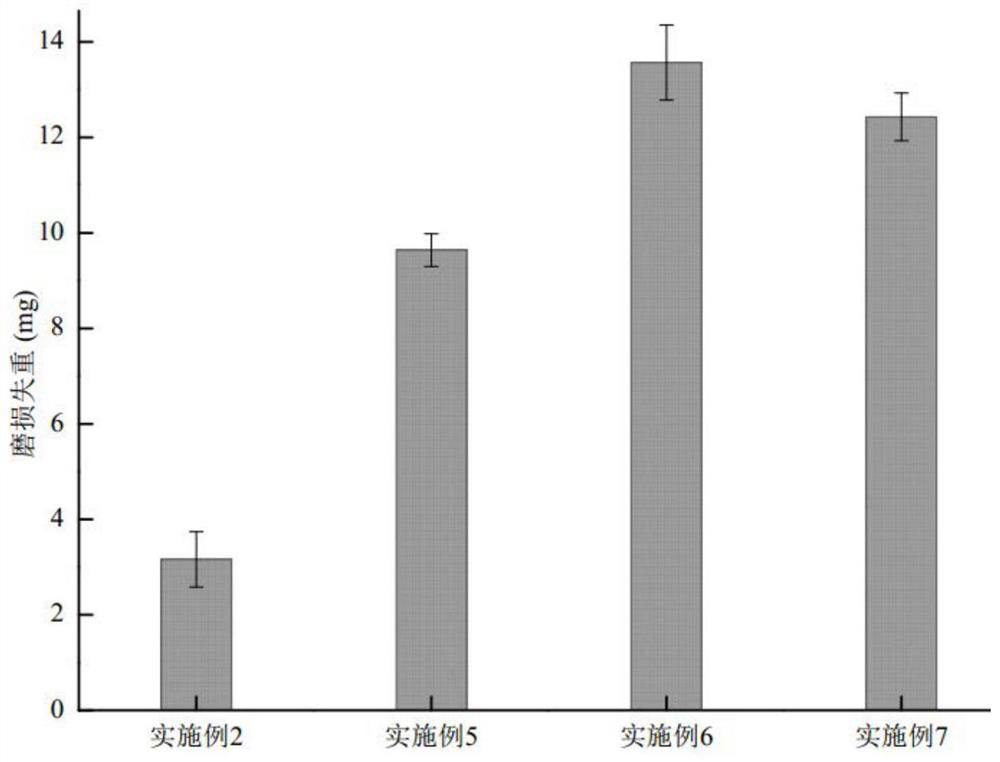

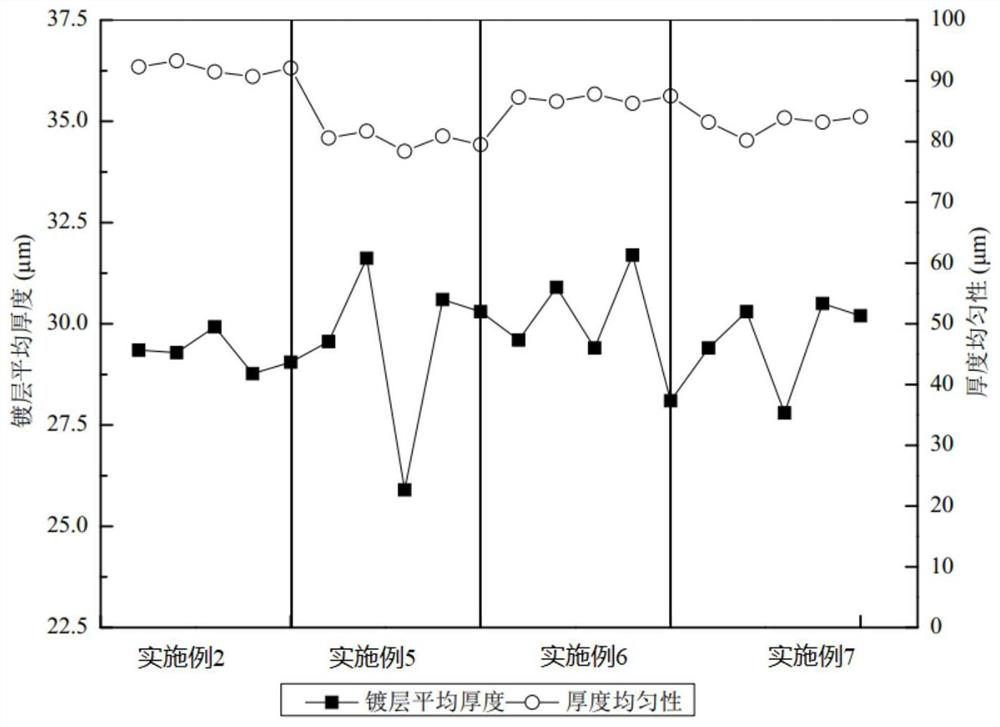

Embodiment 2

[0059] A method for electroplating conductive material on a semiconductor wafer, when working, differs from Embodiment 1 only in that:

[0060] Step 5), the degreasing conditions are: the concentration of potassium hydroxide solution is 150g / L, and the degreasing temperature is 50°C;

[0061] Step 6), the concentration of potassium citrate solution for activation is 50mL / L;

[0062] Step 7), the silver plating conditions are: at a stirring rate of 650rpm, a liquid temperature of 20°C, and a current density of 1.0A / dm 2 Electroplating under the conditions of 15min, after forming a silver coating with a thickness of 25-35μm, the above electroplating solution includes: 7g / L potassium hydroxide, 25g / L silver potassium cyanide, 15mL / L dimethylhydantoin, 80g / L of potassium carbonate, 15g / L of nonylphenol polyoxyethylene ether, 3.5g / L of additives, deionized water as solvent; pH is 7.8; the solvent of the above additives is absolute ethanol, which also has 7g The 2-carboxy-5-fluoro...

Embodiment 3

[0068] A method for electroplating conductive material on a semiconductor wafer, when working, differs from Embodiment 1 only in that:

[0069] Step 5), the degreasing conditions are: the concentration of potassium hydroxide solution is 100g / L, and the degreasing temperature is 40°C;

[0070] Step 6), the concentration of potassium citrate solution for activation is 30mL / L;

[0071] Step 7), the silver plating conditions are: the stirring rate is 600rpm, the liquid temperature is 10°C, and the current density is 0.5A / dm 2 Electroplating under the conditions of 15min, after forming a silver coating with a thickness of 25-35μm, the above electroplating solution includes: 5g / L potassium hydroxide, 20g / L silver potassium cyanide, 10mL / L dimethylhydantoin, Potassium carbonate of 70g / L, nonylphenol polyoxyethylene ether of 10g / L, additive of 1.5g / L, deionized water is solvent; pH is 7.8; The solvent of above-mentioned additive is absolute ethanol, and 9g The sodium bismuth titanat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com