Garment fabric cutting device based on production efficiency improvement for high-end equipment manufacturing

A technology of production efficiency and equipment, applied in the field of garment fabric cutting device, can solve the problems of low precision, unsuitable for small garment factory production and use, complex design, etc., to improve cutting accuracy, improve cutting stability, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

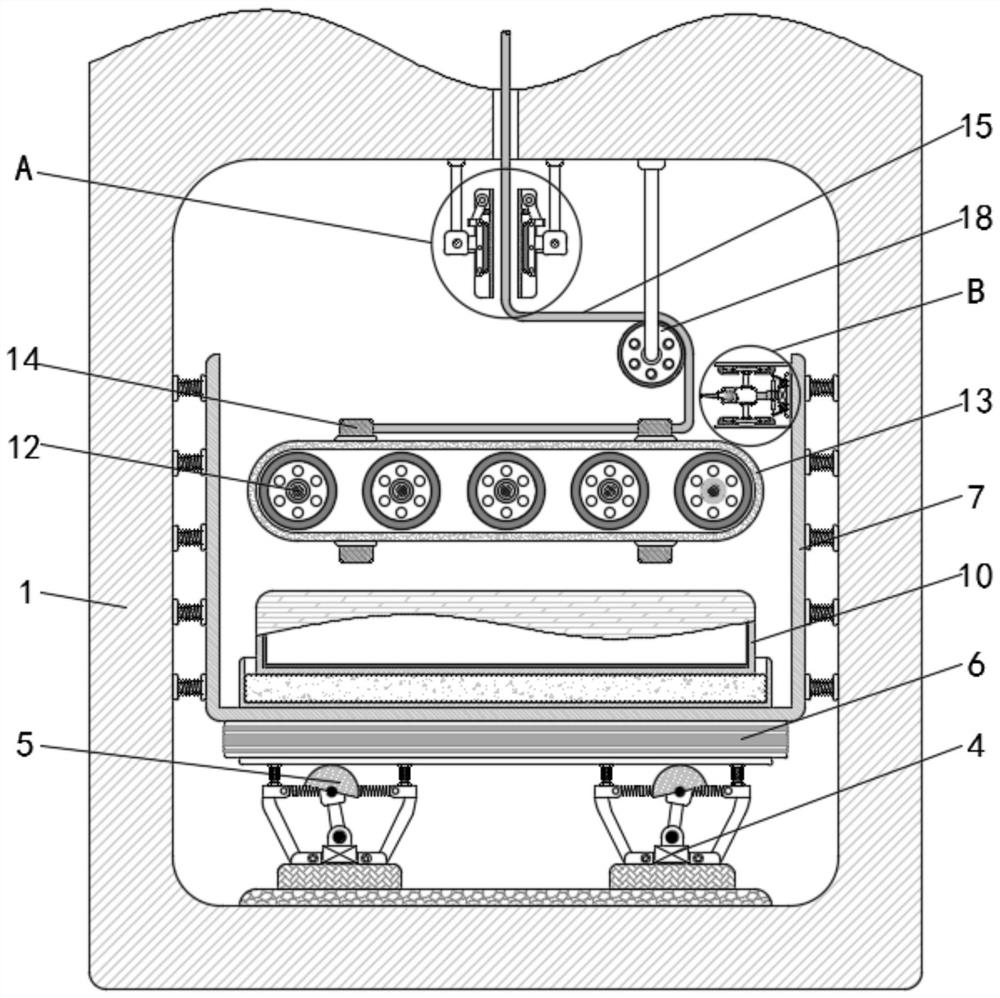

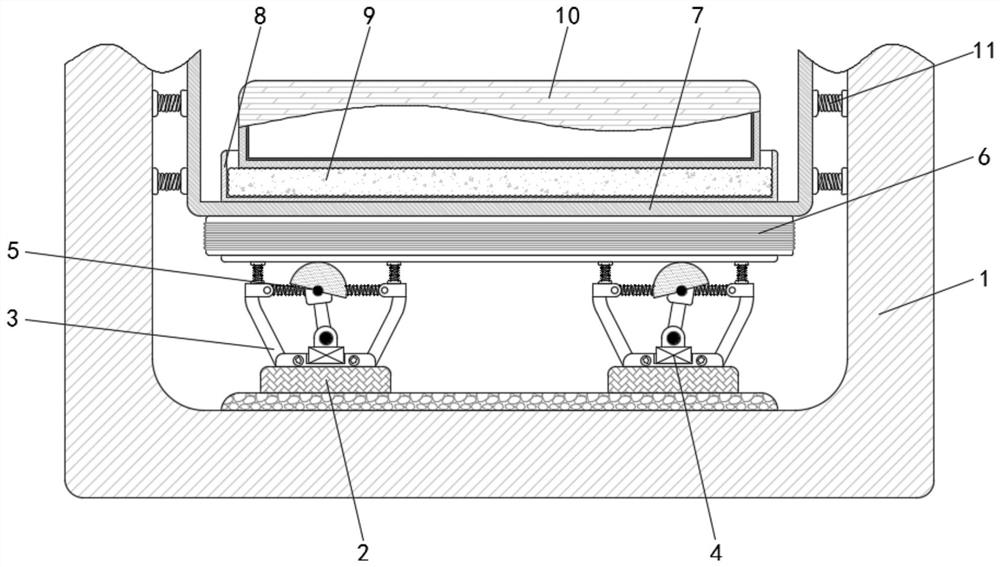

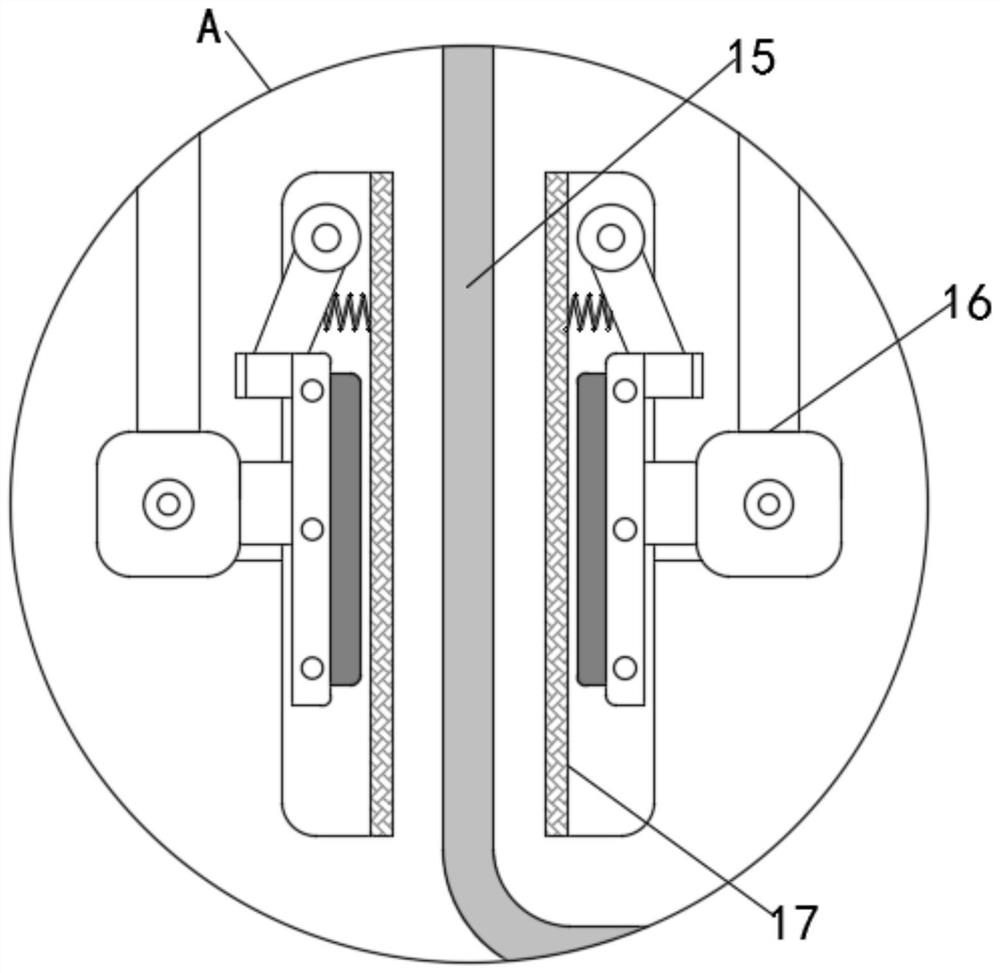

[0023] as attached figure 1 to attach Figure 4 Shown:

[0024] The present invention provides a garment fabric cutting device for high-end equipment manufacturing based on improving production efficiency, which includes a main body 1, a fixed base 2 is fixedly installed on the bottom of the inner wall of the main body 1, and a fixed frame 3 and a reducer are installed on the upper side of the fixed base 2. The shock device 4, the upper side of the shock absorber 4 is provided with a shock absorbing mechanism 5, the upper side of the shock absorbing mechanism 5 is fixedly installed with a consumption air cushion 6, and the upper side of the consumption air cushion 6 is fixedly installed with a mounting shell 7, the mounting shell The inside of 7 is provided with installation assembly 8, and the upper side of installation assembly 8 is provided with collection device 10, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap