Wharf breast wall pipe gallery formwork structure and construction method

A formwork and pipe gallery technology, which is applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of prolonged construction period, long time consumption, and limited construction progress, so as to reduce operation time, improve stability and save money. The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

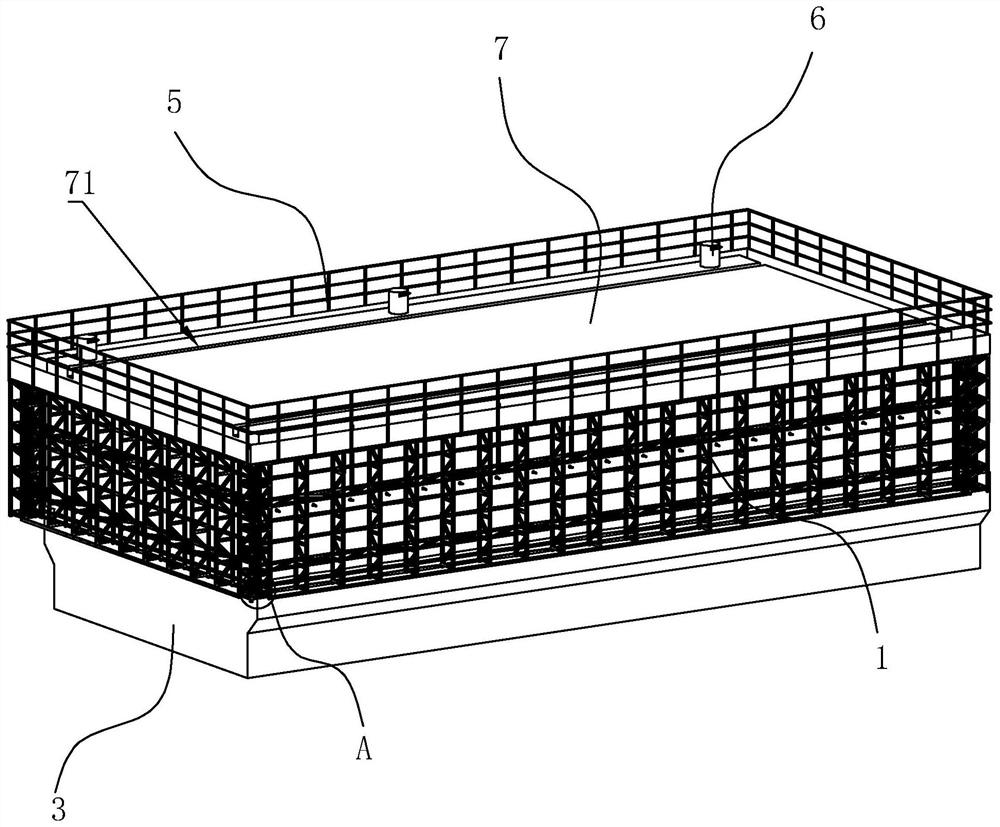

[0048] The embodiment of the present application discloses a formwork structure for a parapet wall pipe gallery of a wharf. refer to figure 1 , several groups of prefabricated caissons 3 are installed on the seabed, each group of caissons 3 is a cuboid, each group of caissons 3 abuts head to tail along its length direction, the extension direction of each group of caissons 3 is perpendicular to the coastline, and the interior of each group of caissons 3 is thrown The upper surface of the caisson 3 is troweled, and the upper surface of the concrete mortar is lower than the plane where the edges of the upper end of the caisson 3 are located. The formwork 1 structure of the breast wall pipe gallery 4 of the wharf includes four sets of formworks 1, and each set of formworks 1 is a prefabricated structure; the upper edge of each set of formworks 1 is welded and fixed with a fence.

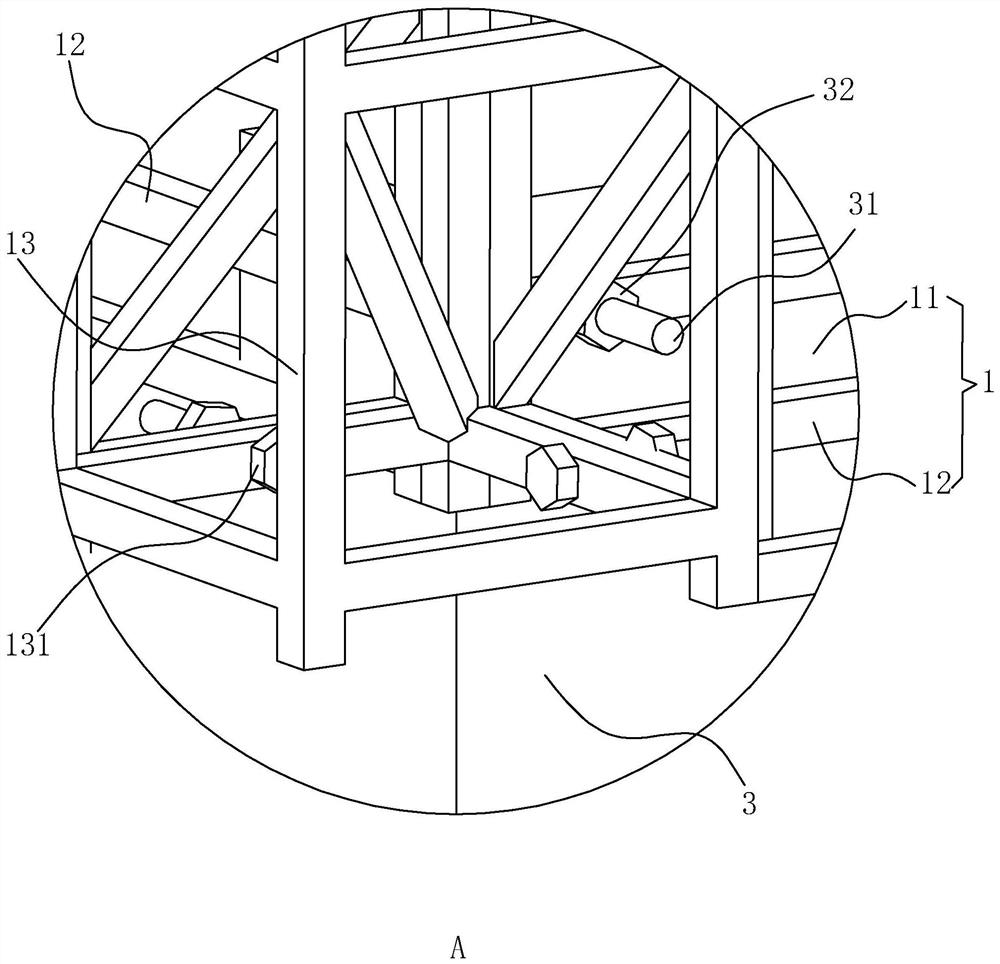

[0049] refer to figure 1 and figure 2 The template 1 includes several groups of brackets 12 and ...

Embodiment 2

[0058] A construction method for the breast wall pipe gallery of a wharf, referring to Figure 4 and Figure 5 :

[0059] a. The caissons 3 are hoisted successively to the seabed by means of hoisting equipment, the upper end faces of the caissons 3 of each group are set horizontally, stones are poured into the caissons 3 of each group and underwater concrete mortar is poured;

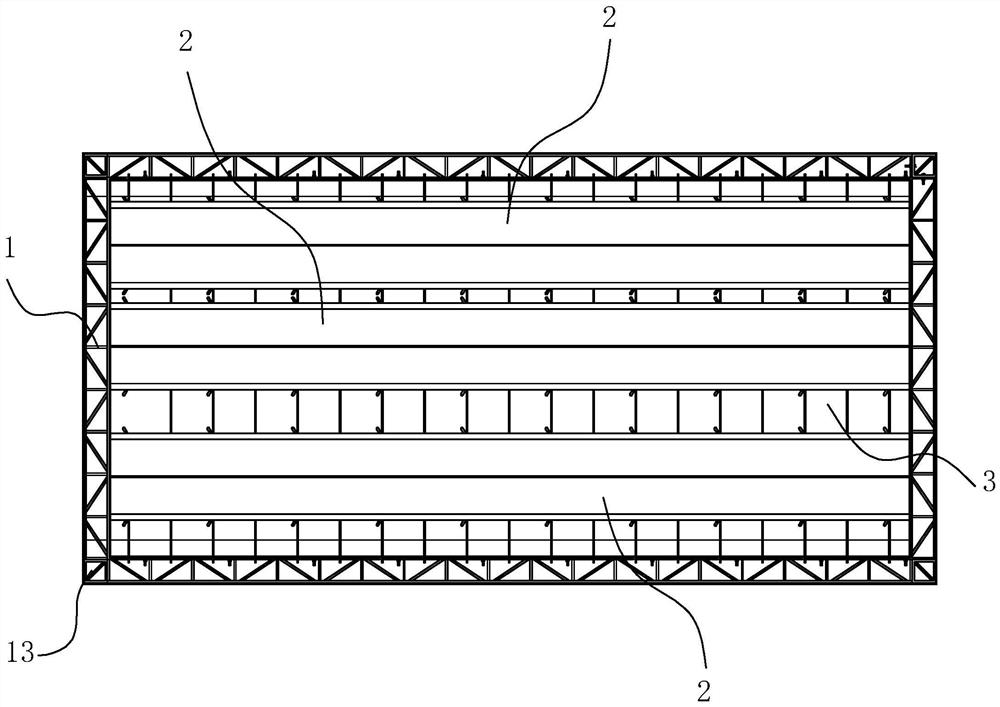

[0060] b. Place each group of stools 2112 on the upper end surface of the caisson 3, each group of stools 2112 is located on the same straight line, a group of mandrel 2 arranges two groups of stools 2112 collinearly arranged, and then each group of pads 23 are laid on each group The upper end surface of the stool 2112; and the inner molds 21 of each group are installed, and the flat plate 2111 on the second plate 211 of each group abuts against the upper end surface of the spacer 23;

[0061] c. Each group of formwork 1 is prefabricated according to the size of the caisson 3, and each group of formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com