A system and method for intelligently compensating interference detection with large local surface shape errors

A technology of interference detection and surface shape error, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of limited precision, limited modes of deformation mirror difference, low detection resolution or detection accuracy, etc., to improve work Performance, Realize Grinding, Effects for Improving Dynamic Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the spirit of the disclosure of the present invention will be clearly described below with the accompanying drawings and detailed descriptions. Any person skilled in the art will understand the embodiments of the present invention. , when it can be changed and modified by the technology taught in the content of the present invention, it does not depart from the spirit and scope of the content of the present invention. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

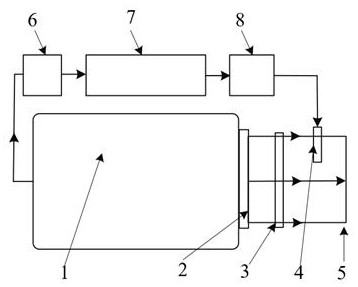

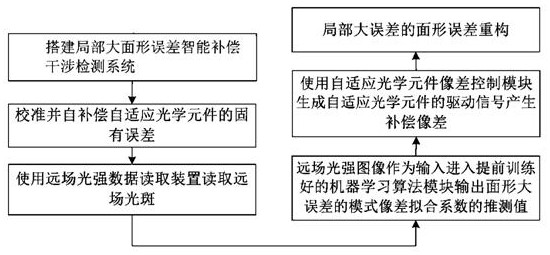

[0037] An intelligent compensation interference detection system for local large surface errors provided in this embodiment includes a wavefront interferometer 1, a standard lens 2, a static compensator 3, an adaptive optical element 4, a surface to be measured 5, and far-field light intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com