Boiler descaling method, descaling system and steaming oven

A technology for steaming ovens and boilers, which is applied in steam boilers, steam boiler accessories, boiler cleaning devices, etc., and can solve problems such as boiler scale accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

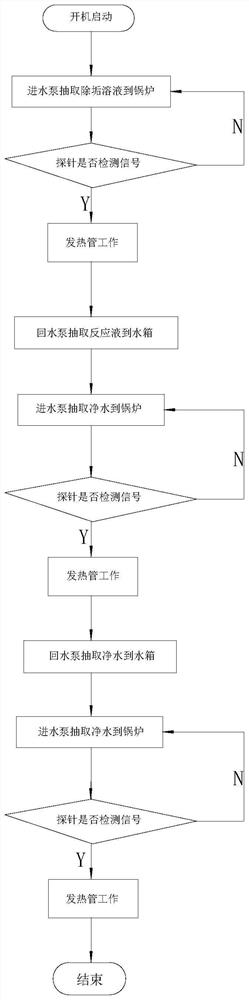

Embodiment 1

[0057]This embodiment provides a boiler descaling method, including: a descaling step, heating the descaling solution in the boiler 3 to a preset temperature T and the descaling solution has not reached a boiling state, and ending the descaling step after time t. The role of the boiler 3 is to provide steam, so the boiler 3 has an air outlet 33 connected to the outside world. The descaling solution has a good descaling effect in a high temperature environment, and as the temperature increases, the descaling effect becomes better and better, but the descaling solution The solute of the solution is water, and the water will boil when the temperature rises. When the water boils, the descaling agent in the descaling solution will flow out from the gas outlet 33 with the steam, forming pollution. In this solution, the temperature rise of the descaling solution is controlled by the preset temperature T, and the descaling solution does not reach a boiling state, which not only ensures...

Embodiment 2

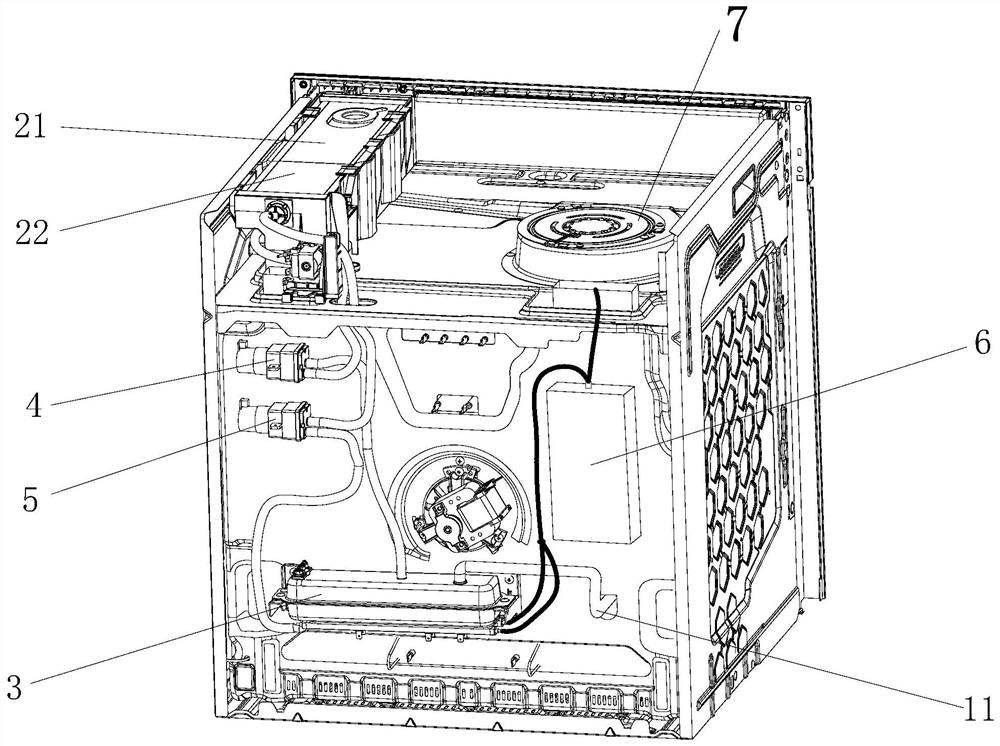

[0066] This embodiment provides a boiler descaling system, including: a water tank 2, including a water purification area 21 and a waste water area 22; Mouth 32; heating module, the heating module includes at least two heating tubes, the heating tubes are suitable for heating the boiler 3; the control module 6 is electrically connected with the heating module through wires, and controls the implementation of the boiler of embodiment 1 3 descaling methods. Using the control module 6 to control the heating tubes of the heating module to work alternately according to the preset program can effectively protect the heating tubes and improve the service life of the heating tubes.

[0067] Specifically, the heat pipe includes a first heat pipe 34 and a second heat pipe 35, and the heating time ratio of the first heat pipe and the second heat pipe is T1:T2. In the case of long-time heating, T1:T2 can be used. Circulation heating. Among them, T1:T2 refers to the ratio of the working ...

Embodiment 3

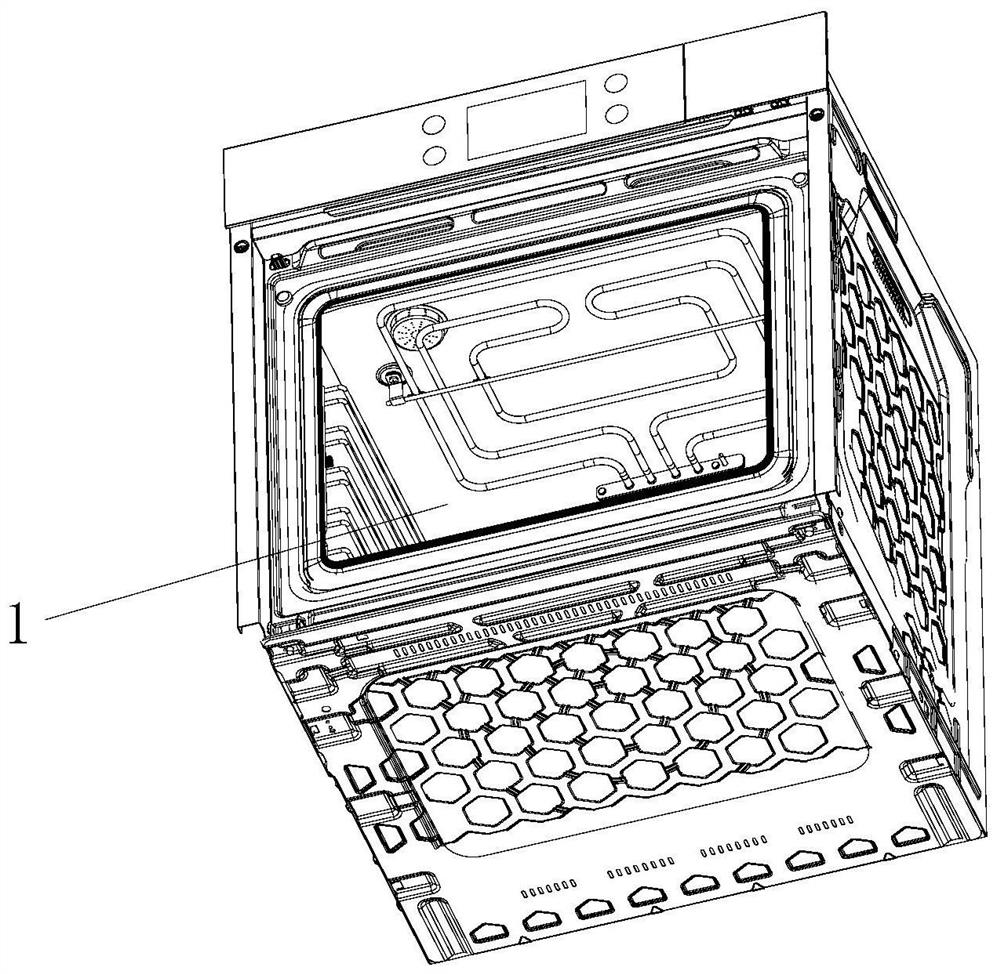

[0072] This embodiment provides a steam oven, such as figure 2 - Figure 5 As shown, it includes: a shell; an inner chamber 1 set in the shell; a boiler 3 descaling system according to any of the above schemes, the water tank 2 is set on the top of the shell. Water is stored in the water tank 2 when the steam oven is in normal use. When descaling is required, a descaling agent is added in proportion to the water tank 2 to form a descaling solution. As an alternative embodiment, a descaling solution tank is added to separately store the descaling solution, and the descaling solution is extracted into the boiler 3 for use when descaling is required.

[0073] Specifically, combine figure 2 , image 3 , the back of the inner chamber 1 is provided with an air inlet 11 , the gas outlet 33 of the boiler is connected to the air inlet 11 , and steam is input into the inner chamber 1 through the air inlet 11 .

[0074] On the basis of the above embodiments, as a further limited em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com