Device and method for measuring thickness of casting powder in continuous casting crystallizer

A continuous casting crystallizer and thickness measurement technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve problems affecting the quality of steel billets, achieve the effects of cost reduction, accurate measurement, and saving mold slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

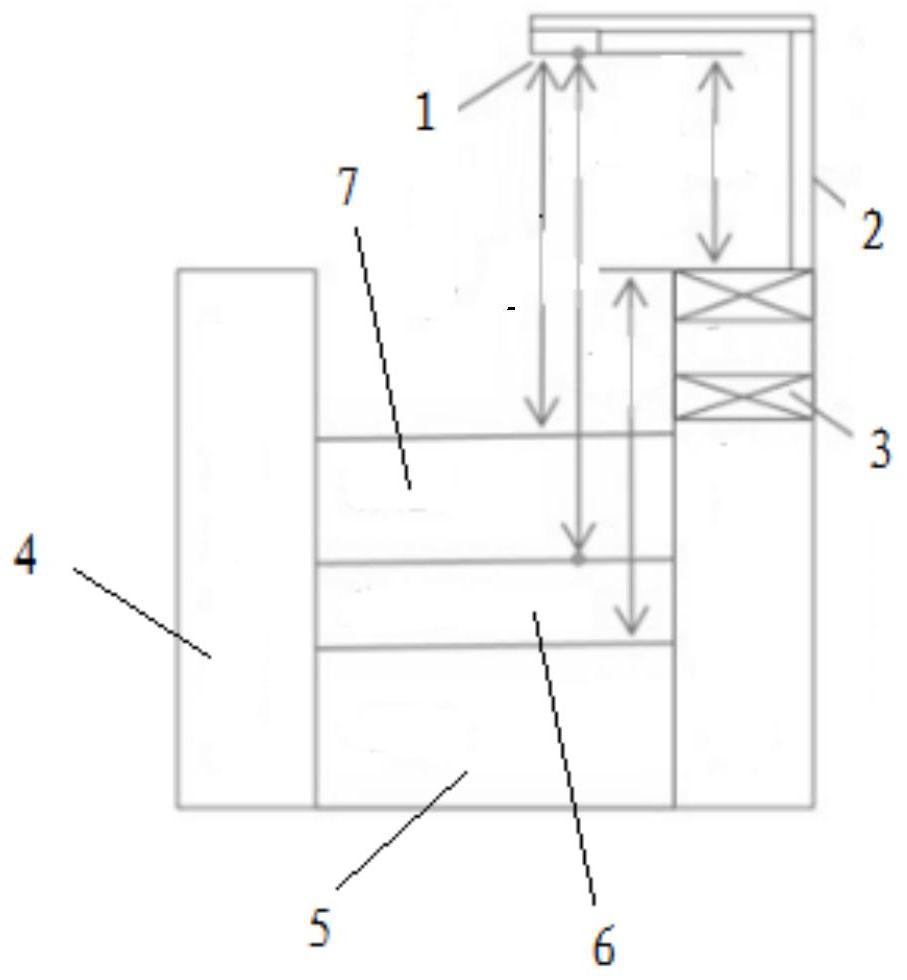

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0015] Millimeter wave electromagnetic waves can propagate well in the air, so non-contact distance measurement can be performed at long distances. In addition, electromagnetic waves are reflected and transmitted at the interface between different materials. The waves reflected from the surface and back of the measurement object can be measured, so that the thickness of the object can be measured. The speed of millimeter wave depends on the relative permittivity of the propagating material, and the relative permittivity of air hardly changes due to different temperatures. In addition, the wavelength is at the millimeter level, and micron-sized particles like dust will not affect the propagation of millimeter waves . Therefore, millimeter waves are especially suitable for continuous casting sites.

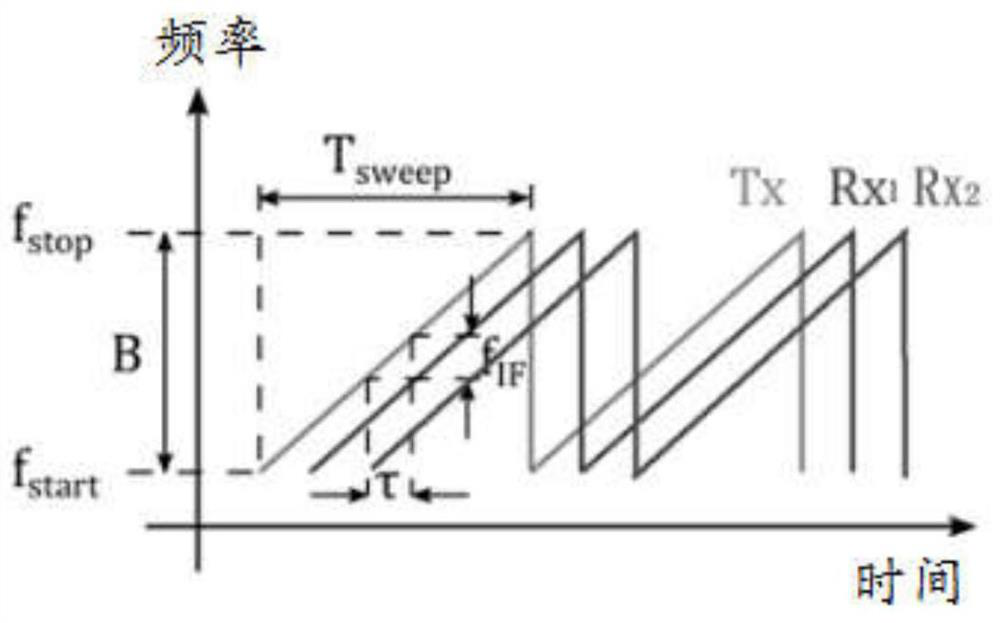

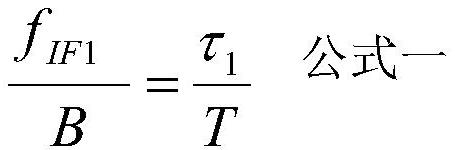

[0016] The present invention adopts LFMCW (Line Frequency Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com