Ultrasound-assisted high-frequency brazing method and device for microminiature superhard cutter

An ultrasonic-assisted, high-frequency brazing technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as air holes and cracks in the welding area, affecting the performance of superhard tools, and affecting the welding performance of superhard tools , to achieve the effect of reducing solidification defects, improving organizational structure and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention relates to a welding method and device for ultrasonic-assisted high-frequency brazing of micro-miniature superhard tools, and is especially suitable for high-strength welding of hard alloy micro tool handles and PCD superhard tool heads.

[0026] The present invention will be further described below in conjunction with accompanying drawing.

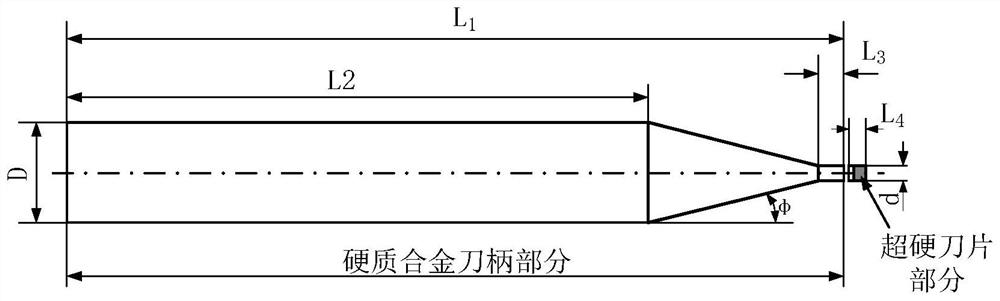

[0027] Such as figure 1 As shown, the superhard tool is composed of a carbide handle and a PCD (polycrystalline diamond) head, which is welded on the top of the handle. Among them, the size of the tool handle and cutter head used in this example is: D=3mm, d=0.5mm, L 1 =50mm,L 2 =40mm, L 3 = 2mm, L 4 = 1.6 mm.

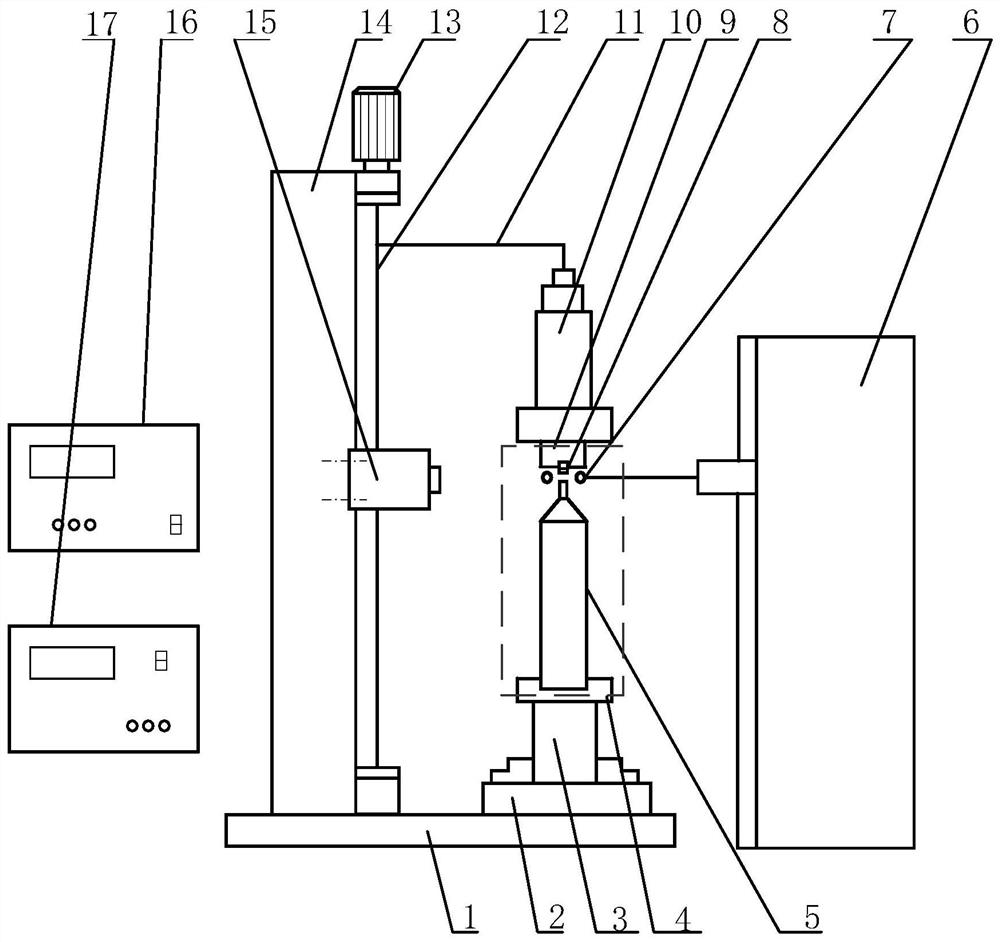

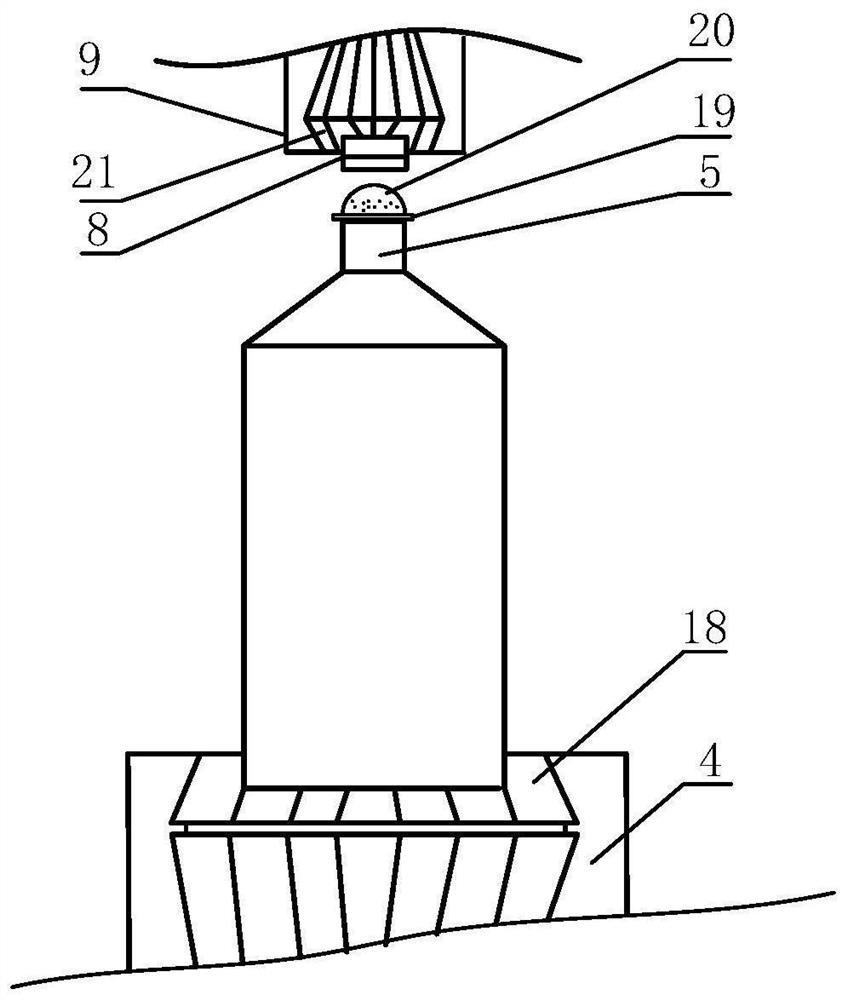

[0028] figure 2 and image 3 The main structure of ultrasonic-assisted high-frequency brazing for micro-miniature superhard tools, including:

[0029] The base 1, the support base 2 and the column 14 are all fixed on the base 1;

[0030] The clamping device includes a knife handle seat 4 and a knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com