High-content heavy element doped beta-FeSi2-based thermoelectric material and preparation method thereof

A technology of thermoelectric materials and heavy elements, which is applied in the directions of thermoelectric device junction lead-out materials, metal silicides, etc., can solve the problem that the thermoelectric properties of β-FeSi2 materials have not made a big breakthrough, and achieve thermal stability performance and anti-oxidation performance. Outstanding, broad application prospects, environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

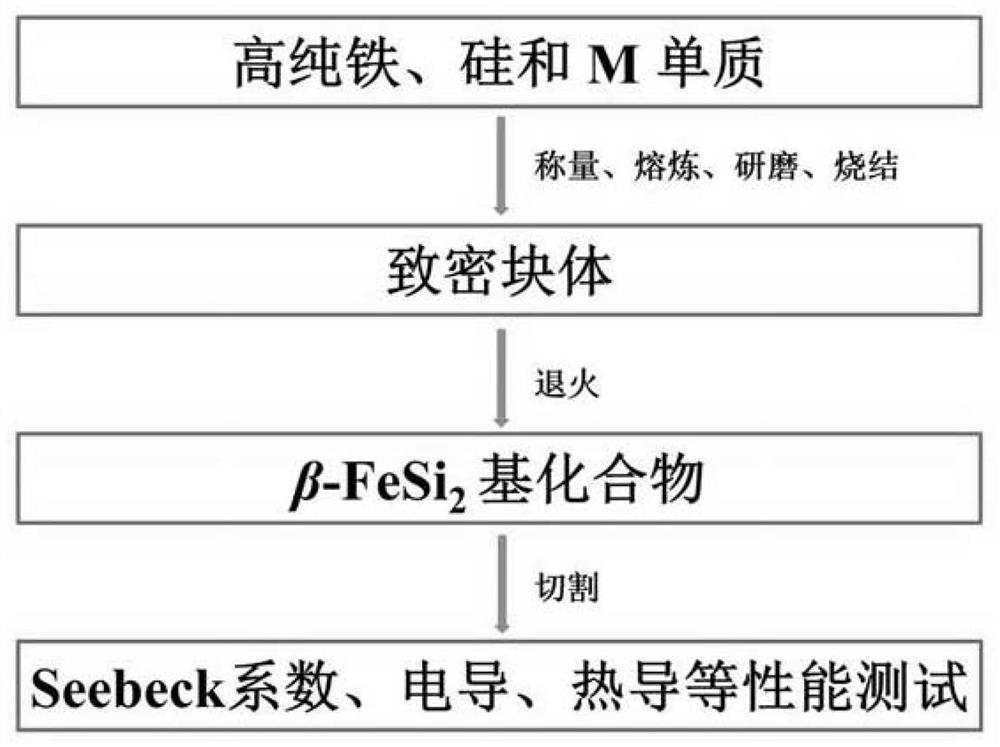

Method used

Image

Examples

Embodiment 1

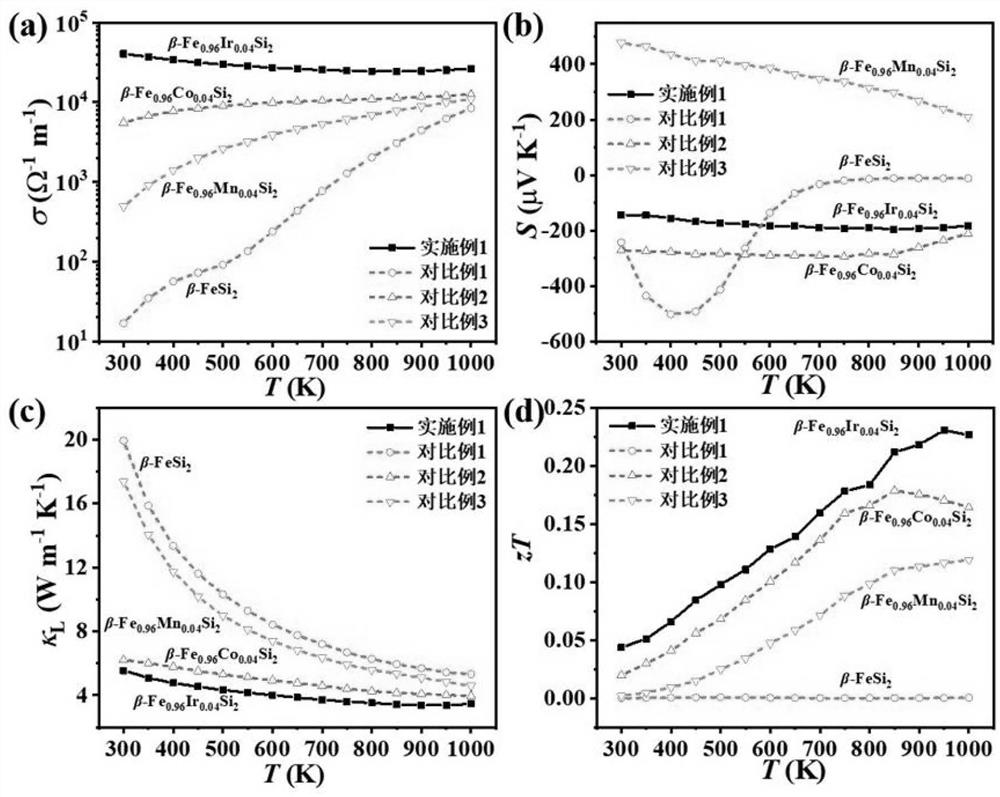

[0046] β-Fe 0.96 Ir 0.04 Si 2 (M is Ir and x=0.04) semiconductor material polycrystalline body:

[0047] The raw material Fe, Ir and Si are mixed according to the molar ratio of 0.96:0.04:2, melted at 1750°C to become a liquid melt, and then condensed at a cooling rate of 20°C / s to obtain an ingot sample;

[0048] Grinding the ingot into powder, and performing discharge plasma sintering, the sintering temperature is 900°C, the sintering pressure is 65MPa, the sintering time is 10 minutes, the sintering atmosphere is a low-pressure argon atmosphere, and the pressure is 0.07MPa to obtain a dense block;

[0049] The dense block is vacuum-packed in a quartz tube and placed together in an annealing furnace for heat treatment. The details are as follows: heat up to 1150°C at a heating rate of 100°C / hour, hold for 24 hours, then drop to 900°C at a cooling rate of 100°C / hour, cool to room temperature after holding for 120 hours, and finally obtain β-Fe 0.96 Ir 0.04 Si 2 compound...

Embodiment 2

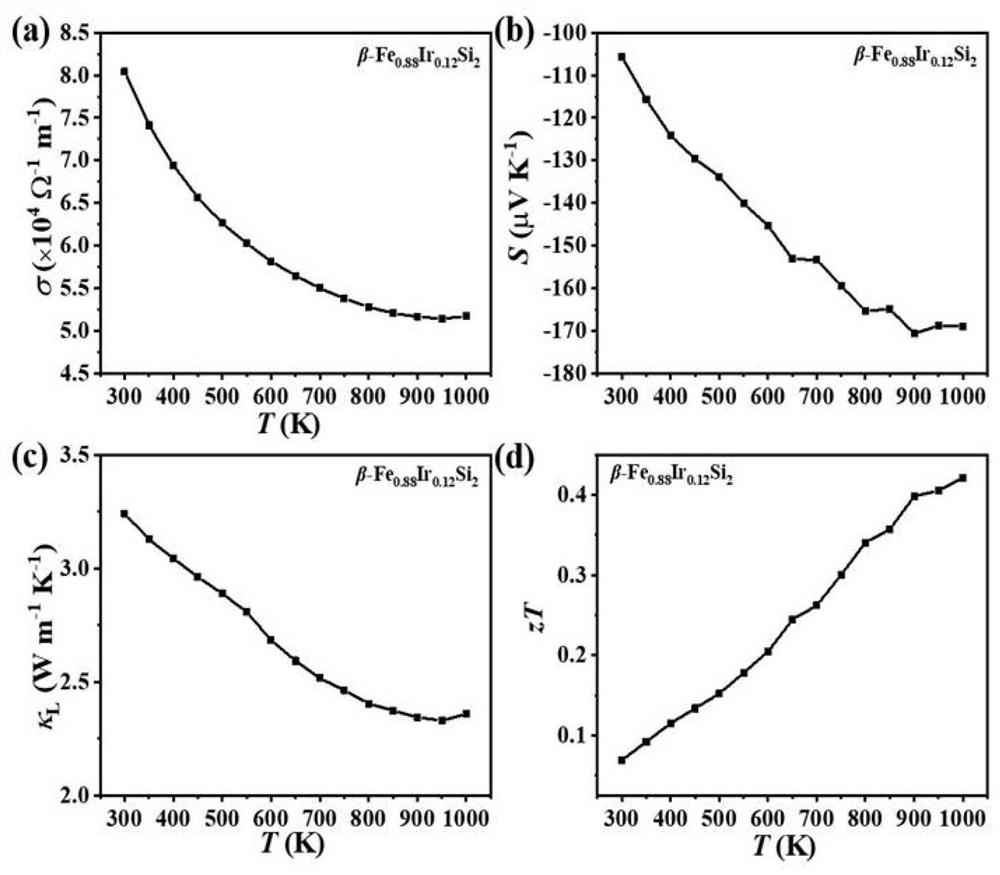

[0058] In this embodiment 2, β-FeSi 2 The preparation process of the base thermoelectric material is basically the same as in Example 1, with the difference: x=0.12.

[0059] Such as image 3 As shown, the resulting β-Fe 0.88 Ir 0.12 Si 2 The thermoelectric performance measurement of the polycrystalline block shows that in the measured temperature range (300-1000K), the material has moderate electrical conductivity (the electrical conductivity is 50000-85000Ω -1 m -1 between) and the Seebeck coefficient (the absolute value of the Seebeck coefficient value is between 100 and 180μV K -1 between). At the same time, the material exhibits low lattice thermal conductivity (the lattice thermal conductivity is between 2.0 and 3.5W m -1 K -1 between). The zT value of this material calculated from the property measurements is close to 0.42 at 1000K.

Embodiment 3

[0061] β-FeSi in this embodiment 3 2 The preparation process of the base thermoelectric material is basically the same as that of Example 1, with the difference: x=0.20.

[0062] Such as Figure 4 As shown, the resulting β-Fe 0.80 Ir 0.20 Si 2 The thermoelectric performance measurement of the polycrystalline block shows that in the measured temperature range (300-1000K), the material has moderate electrical conductivity (the electrical conductivity is 75000-120000Ω -1 m -1 between) and the Seebe coefficient (the absolute value of the Seebeck coefficient value is between 90 and 160μV K -1 between). At the same time, the material exhibits low lattice thermal conductivity (the lattice thermal conductivity is between 1.5 and 2.5W m -1 K -1 between). The zT value of this material calculated from the property measurements is close to 0.62 at 1000K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com