Preparation method of diene dielectric elastomer

A technology of dielectric elastomer and diene, which is applied in the field of preparation of diene dielectric elastomer, can solve the problems of difficult dispersion of nanometer dielectric particles, improved dielectric loss and electrical conductivity, poor interface compatibility, etc. Mechanical modulus, high dielectric constant, effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

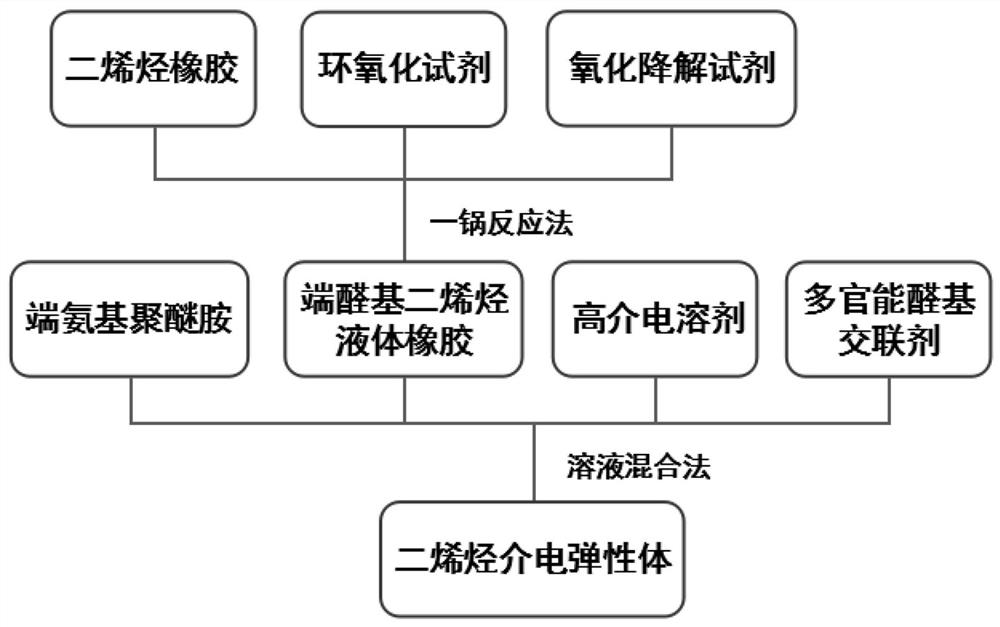

[0041] The preparation method of the diene dielectric elastomer provided by the invention is carried out according to the following sequence of steps:

[0042] S1. Preparation of aldehyde-terminated diene liquid rubber

[0043] S2. Mixing aldehyde-terminated diene liquid rubber, amino-terminated polyether amine, high dielectric solvent, and multifunctional aldehyde-based crosslinking agent in an organic solvent, volatilizing the solvent and then heating and curing to obtain a diene dielectric elastomer.

[0044] Specifically, step S1 is performed in the following order:

[0045] S11, dissolving the diene rubber in the reaction medium to obtain a rubber solution with a concentration of 25g / L-100g / L;

[0046] S12. Add an epoxidation reagent to the rubber solution, and react at 25-30° C. for 0.5-4 hours to obtain a solution A;

[0047] Wherein the consumption of epoxidation reagent is 0.5%~5% of the molar weight of diene rubber;

[0048] S13. Add an oxidative degradation reage...

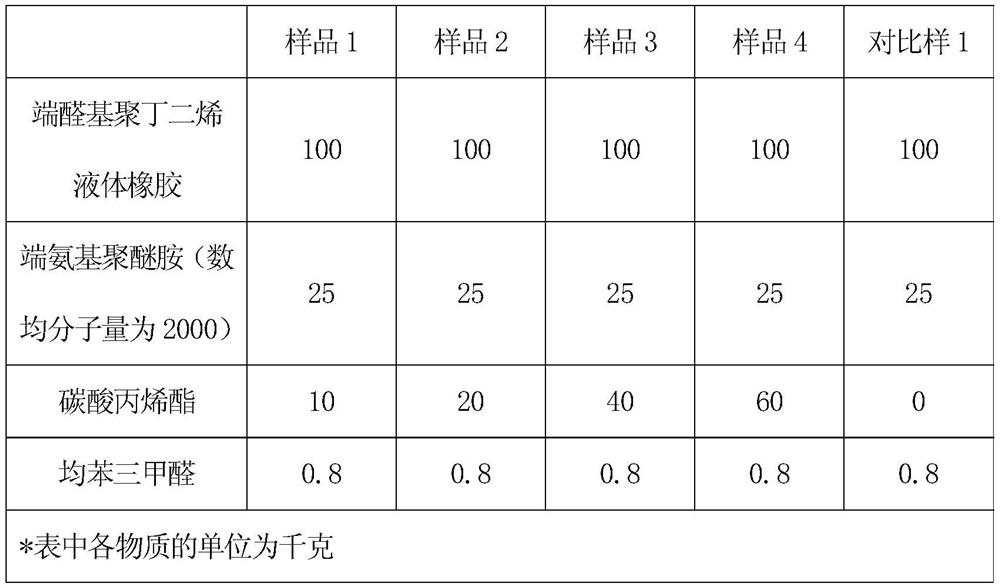

Embodiment 1

[0060] Embodiment 1 A kind of preparation method of terminal aldehyde group polybutadiene dielectric elastomer

[0061] Such as figure 1 As shown, this embodiment is carried out according to the following steps in sequence:

[0062] Preparation of S1, aldehyde-terminated polybutadiene liquid rubber:

[0063] S11, 25kg of polybutadiene rubber is completely dissolved in 1000L of cyclohexane at 25°C to obtain a rubber solution with a concentration of 25g / L;

[0064] S12. Add peroxybenzoic acid to the rubber solution under stirring, and react at 25° C. for 1 hour to obtain solution A1;

[0065] The consumption of peroxybenzoic acid is 1% of polybutadiene rubber unit molar weight;

[0066] S13. Add periodic acid to the solution A1 under stirring, and react at 25° C. for 1 hour to obtain the product B1;

[0067] The consumption of periodic acid is 120% of peroxybenzoic acid molar weight;

[0068] S14, washing the product B1 with distilled water to neutrality, and volatilizing t...

Embodiment 2

[0083] Embodiment 2 A kind of preparation method of aldehyde-terminated nitrile butyronitrile dielectric elastomer

[0084] Such as figure 1 As shown, this embodiment is carried out according to the following steps in sequence:

[0085] S1, preparation of aldehyde-terminated nitrile liquid rubber:

[0086] S11, 15kg of nitrile rubber is completely dissolved in 200L of tetrahydrofuran at 30°C to obtain a rubber solution with a concentration of 75g / L;

[0087] S12. Add peracetic acid to the rubber solution under stirring, and react at 30°C for 1.5 hours to obtain solution A2;

[0088] The consumption of peroxybenzoic acid is 2.5% of the nitrile rubber unit molar weight;

[0089] S13. Under stirring, add perchloric acid to the solution A2, and react at 30° C. for 1.5 hours to obtain the product B2;

[0090] The consumption of perchloric acid is 130% of peracetic acid molar weight;

[0091] S14, the product B2 is washed with distilled water until neutral, and the solvent is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com