Wellhead wax deposition prevention mechanism and wax deposition prevention process

A technology of anti-wax deposition and process, which is applied in the direction of wellbore/well components, isolation devices, cleaning equipment, etc. It can solve the problems of unstable delivery of chemical adding devices, incomplete wax removal process, and poor wax removal effect. Achieve the effects of shortening the wax removal cycle, simple structure, and stable material transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

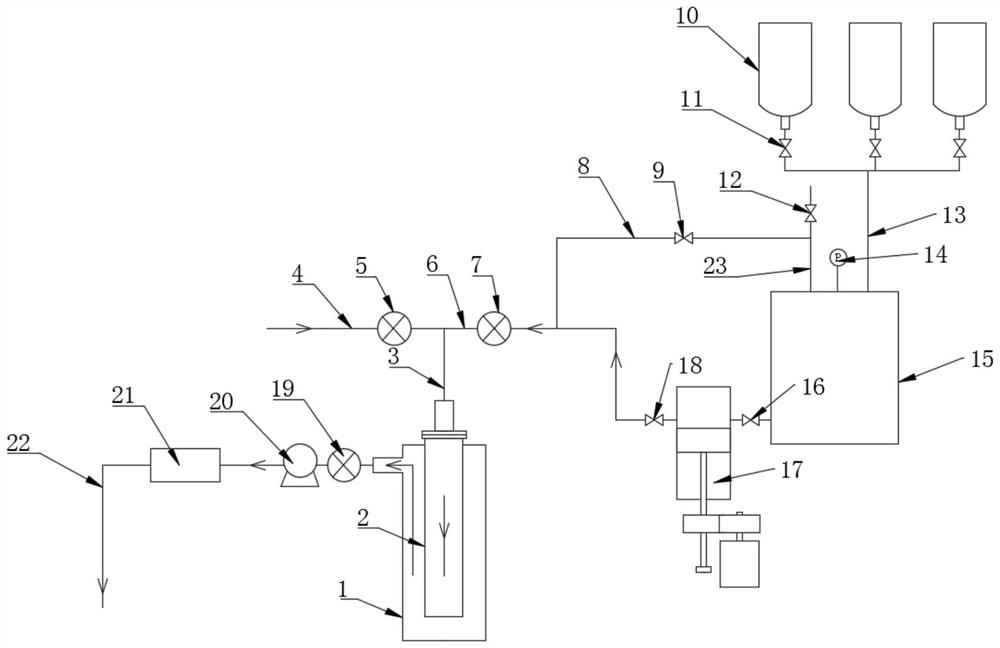

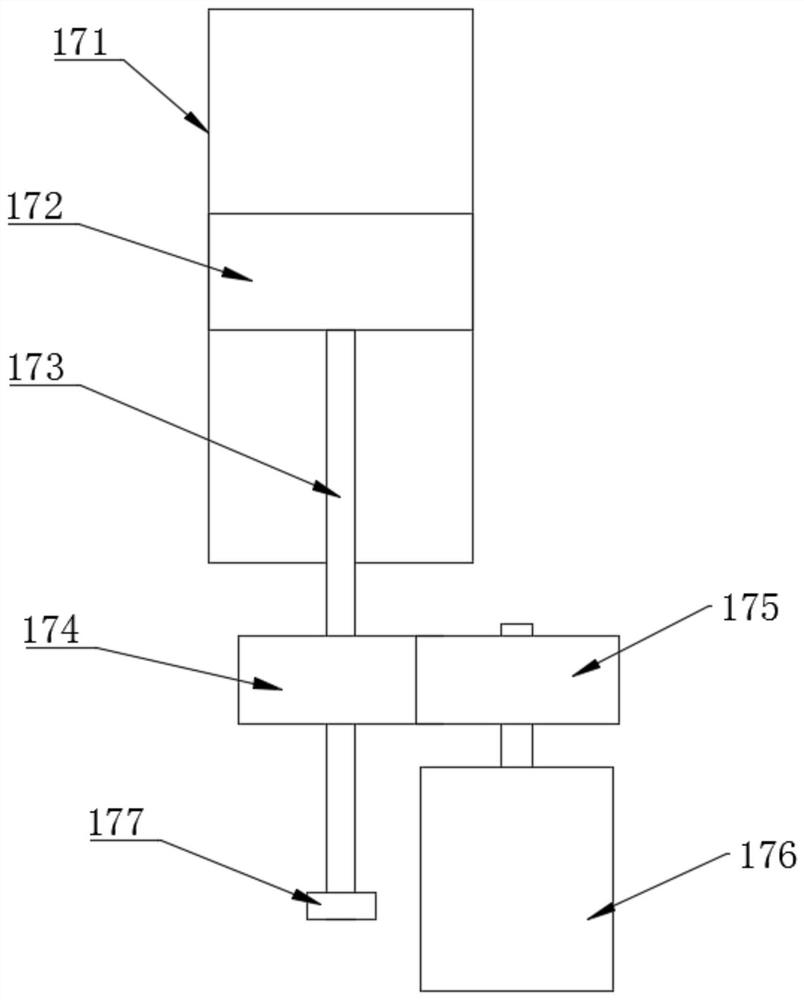

[0027] Such as figure 1 , figure 2 As shown, the present invention provides a wellhead anti-waxing mechanism, which includes a downhole casing 1, the downhole casing 1 is set outside the tubing 2, the top of the tubing 2 is connected with a feed main pipe 3, and the feed main pipe 3 is respectively connected with a parallel The air inlet pipe 4 and the medicine feeding pipe 6 are provided with the air inlet valve 5 on the air inlet pipe 4, and the medicine feeding valve 7 is provided on the medicine feeding pipe 6, and the medicine feeding pipe 6 is further connected with a power unit 17, a dosing tank 15, The medicine continuing device, the downhole casing 1 is connected with a discharge pipe 22, and the discharge pipe 22 is provided with a discharge valve 19 and a discharge pump 20.

[0028] In this embodiment, hot steam is passed into the oil pipe 2 through the intake pipe 4, and the intake valve 5 is used to control the on-off of the intake pipe 4; 6 is delivered to the...

Embodiment 2

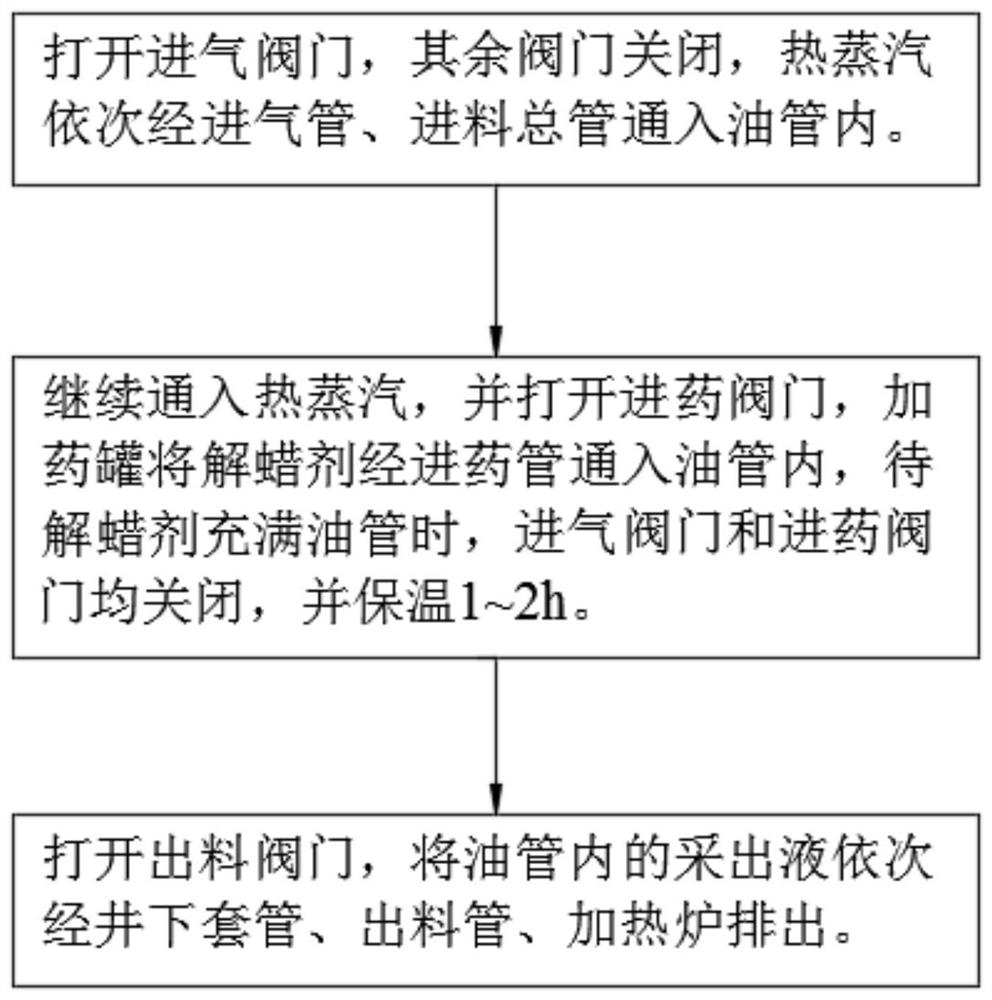

[0039] Such as image 3 As shown, the present invention also provides a kind of well head anti-wax process, comprises the following steps:

[0040] Step 1: Open the intake valve 5, and close the other valves, and the hot steam is passed into the oil pipe 2 through the intake pipe 4 and the main feed pipe 3 in sequence. Among them, the hot steam temperature is at least 120°C, the time is 2-3 hours, and the water consumption is 3-5m3.

[0041] Step 2, continue to feed hot steam, and open the medicine inlet valve 7, the dosing tank 15 passes the deparaffin agent into the oil pipe 2 through the medicine inlet pipe 6, and when the oil pipe 2 is filled with the deparaffin agent, the air inlet valve 5 and the inlet valve Medicine valves 7 are all closed and kept warm for 1-2 hours. Among them, the temperature of the hot steam is 110-130°C, the time is 4-5 hours, and the water consumption is 4-6m3.

[0042] Step 3, open the discharge valve 19, and discharge the production fluid in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com