Method for measuring oil content of drilling solid waste

A solid waste and determination method technology, applied in the field of inspection and detection, can solve the problems affecting the accuracy of the results, low sensitivity, etc., and achieve the effects of accelerating the extraction speed, improving the measurement accuracy, and ensuring the detection limit requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

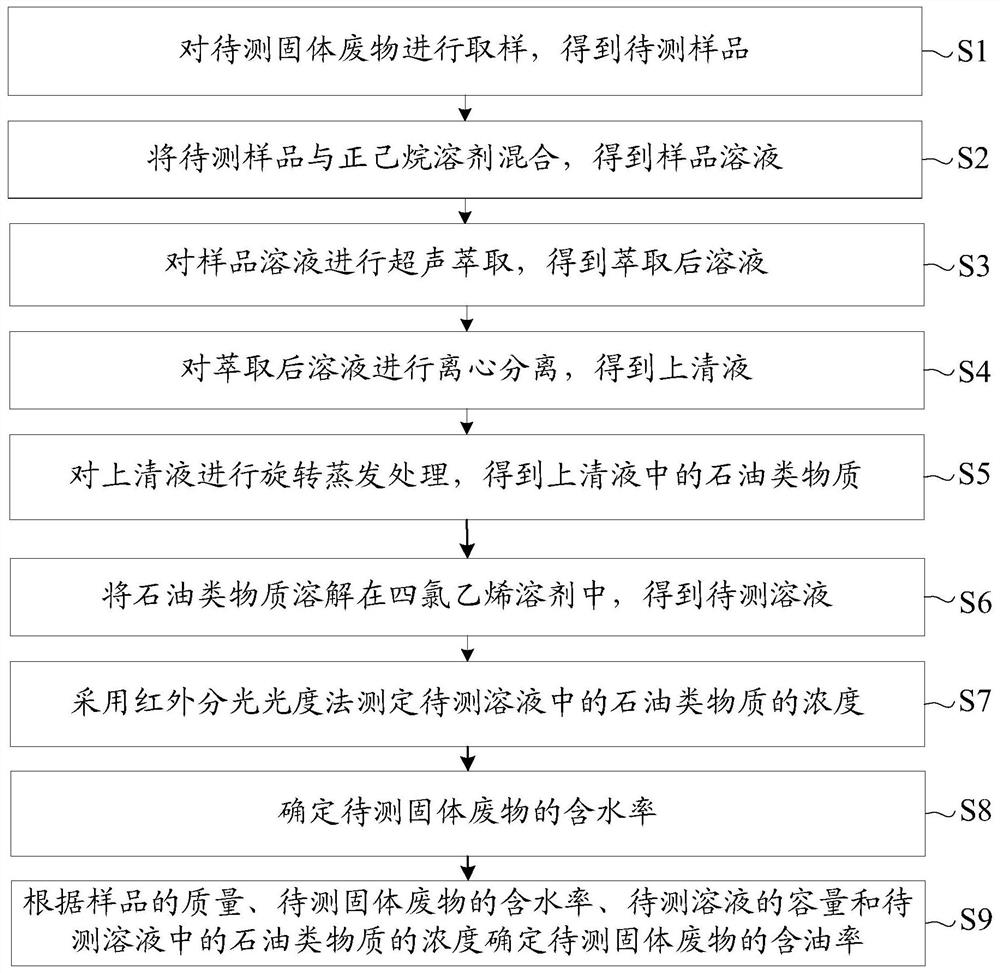

[0039] figure 1 It is a flowchart of a method for measuring the oil content of drilling solid waste provided by an embodiment of the present disclosure. see figure 1 , the methods for determining the oil content of drilling solid waste include:

[0040] Step S1: Sampling the solid waste to be tested to obtain a sample to be tested.

[0041] In the embodiments of the present disclosure, the amount of solid waste to be tested is generally large, and it is more convenient to use a sample instead of the whole by sampling the solid waste to be tested.

[0042] Exemplarily, when sampling the solid waste to be tested, the mass of the sample to be tested may be determined first, and a certain amount of solid waste to be tested is weighe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com