A laser punching machine

A punching machine and laser technology, applied to structural parts, electrical components, battery electrodes, etc., can solve problems such as battery leakage, burr defect missed detection, poor detection quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

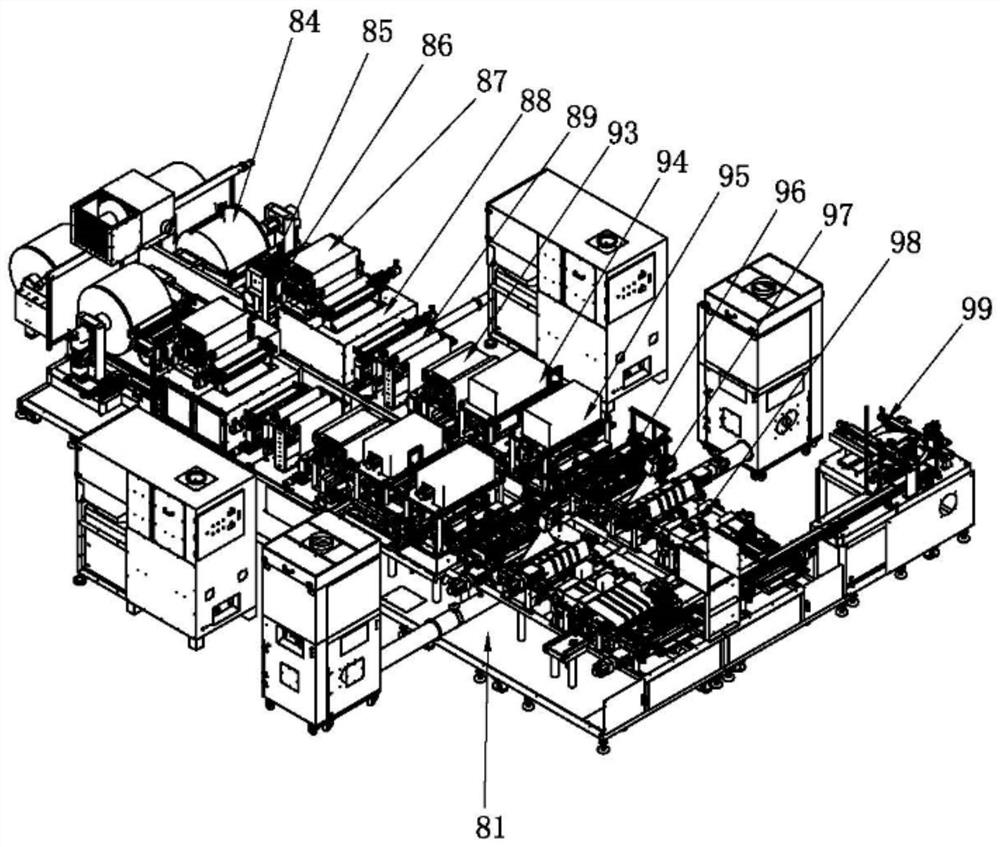

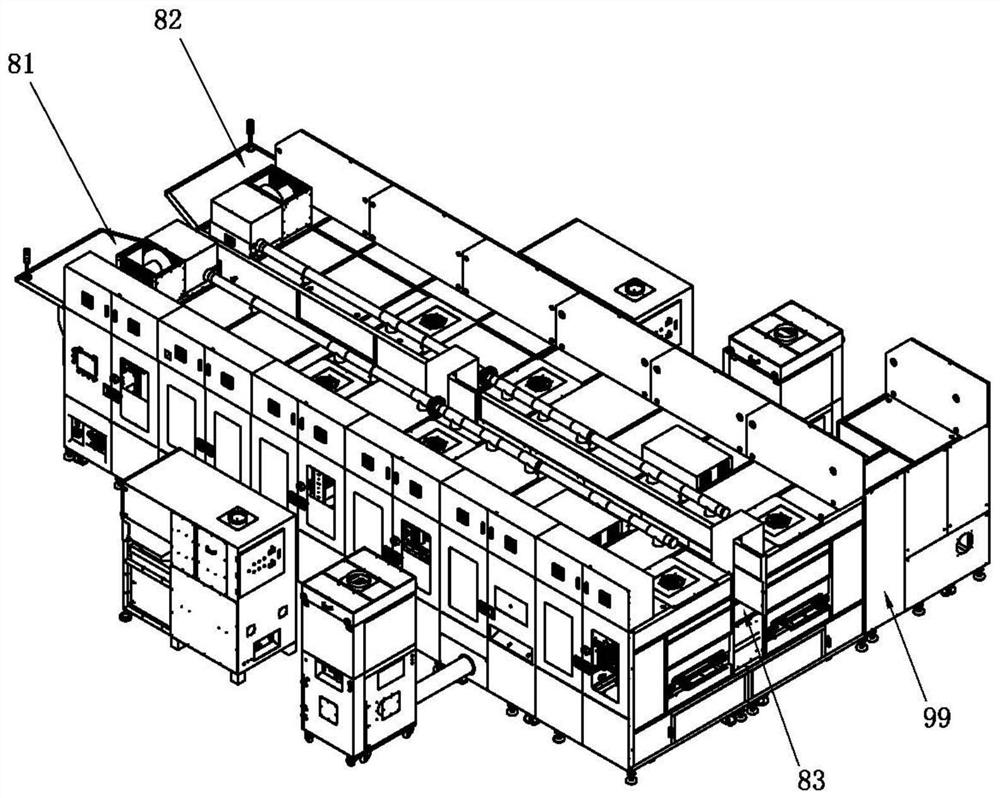

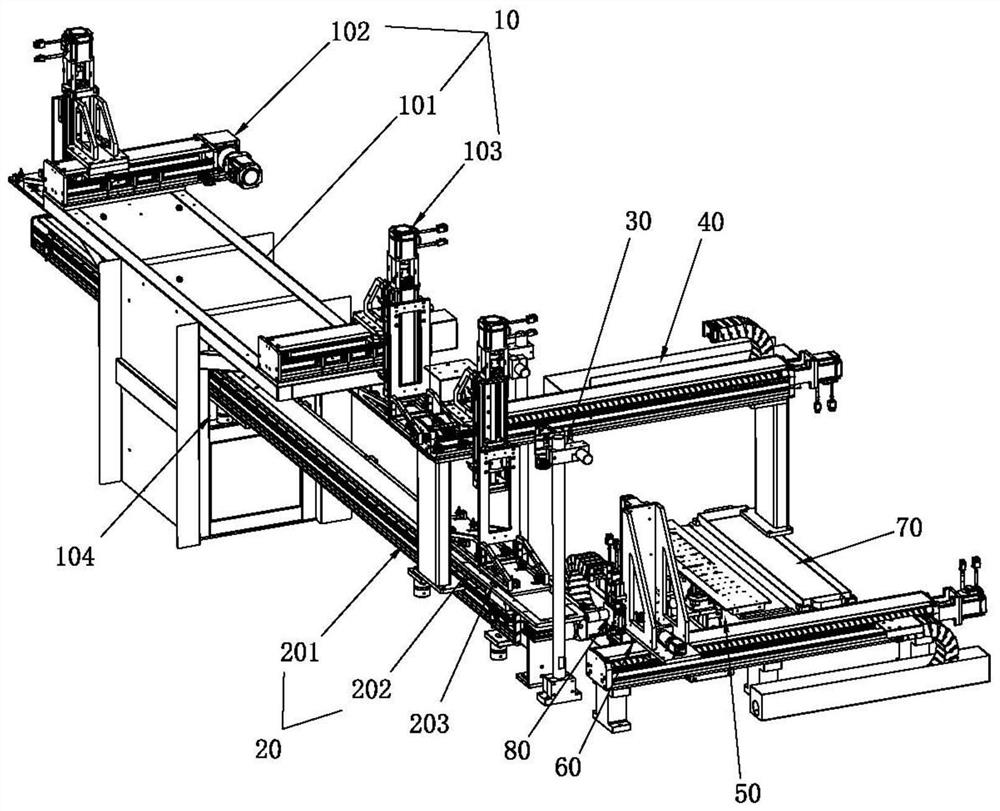

[0032] Such as Figure 1 to Figure 12 As shown, a laser punching machine provided by the present invention includes a positive electrode sheet forming device 81, a negative electrode sheet forming device 82 arranged in parallel with the positive electrode sheet forming device 81, and a positive electrode sheet formed by the positive electrode sheet forming device 81. The pole piece burr sampling equipment 99 for spot-checking the negative pole piece formed by the negative pole piece forming equipment 82, the pole piece burr sampling equipment 99 includes a pole piece sampling feeding device 10, a pole piece conveying device 20, a visual positioning device 30, a pole piece A piece transfer dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com