A high voltage pn bridge gate drive circuit

A gate drive circuit and drive circuit technology, applied in the direction of electrical components, output power conversion devices, etc., can solve the problems of complex structure of PN bridge drive circuit and impossibility to realize thin gate oxide device technology, so as to reduce the complexity of circuit structure, Effects of layout size reduction and static power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

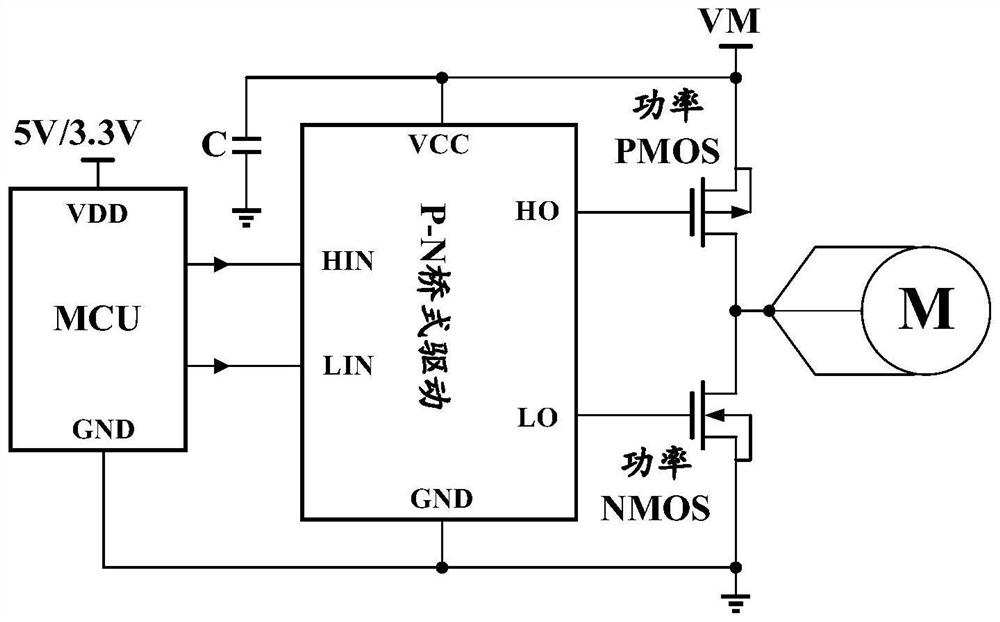

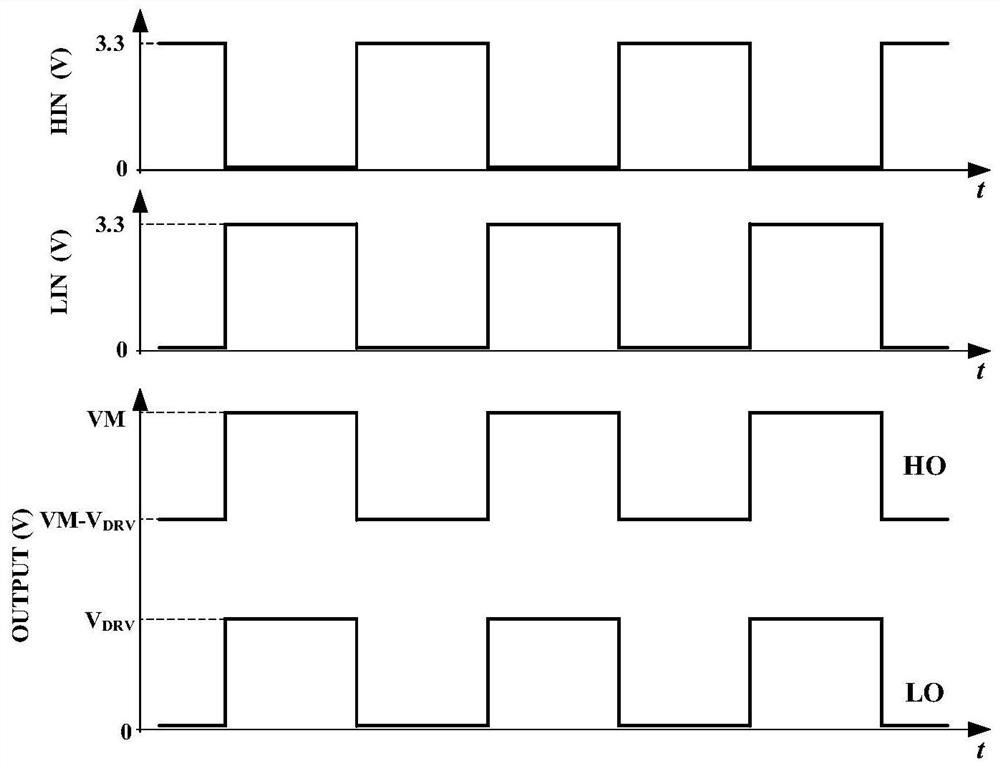

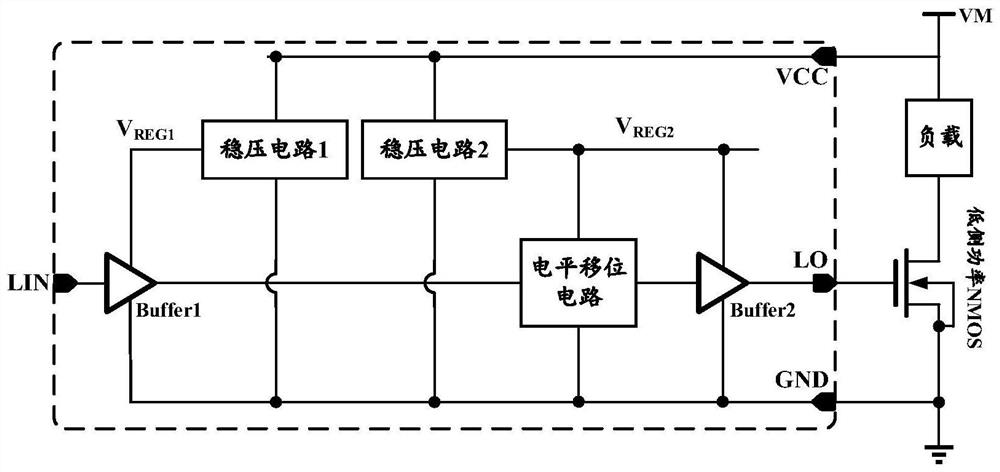

[0032] The invention provides a high-voltage PN bridge gate drive circuit for driving a PN bridge. The PN bridge includes a high-side load high-voltage PMOS transistor and a low-side load high-voltage NMOS transistor, and the drive circuit includes an input stage circuit, a voltage regulator circuit, and a level conversion circuit. , gate voltage control circuit, I-V conversion circuit, output voltage detection circuit, the first power device PMOS tube and the second power device NMOS tube, the voltage regulator circuit is connected between VCC and the input stage circuit to supply power for the input stage circuit, The input end of the input stage circuit is the input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com