Fragrance sustained-release capsule and preparation method thereof

A technology of slow-release capsules and aroma, which is applied in the direction of microcapsule preparation, preparation of microspheres, gasification substances, etc., can solve the problems of excessive aroma volatilization, pollution of human health, waste of resources and the environment, and achieve enhanced aroma sustained-release capabilities , Prolong the single use time and reduce the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

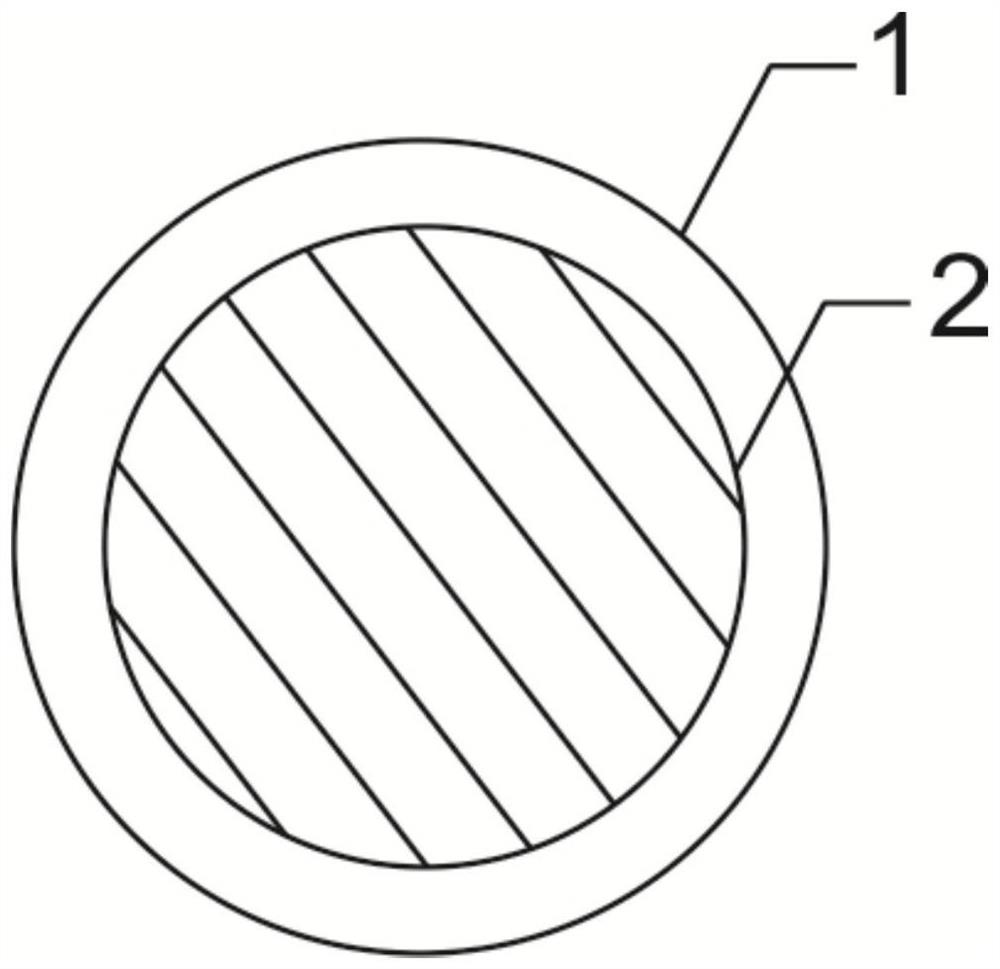

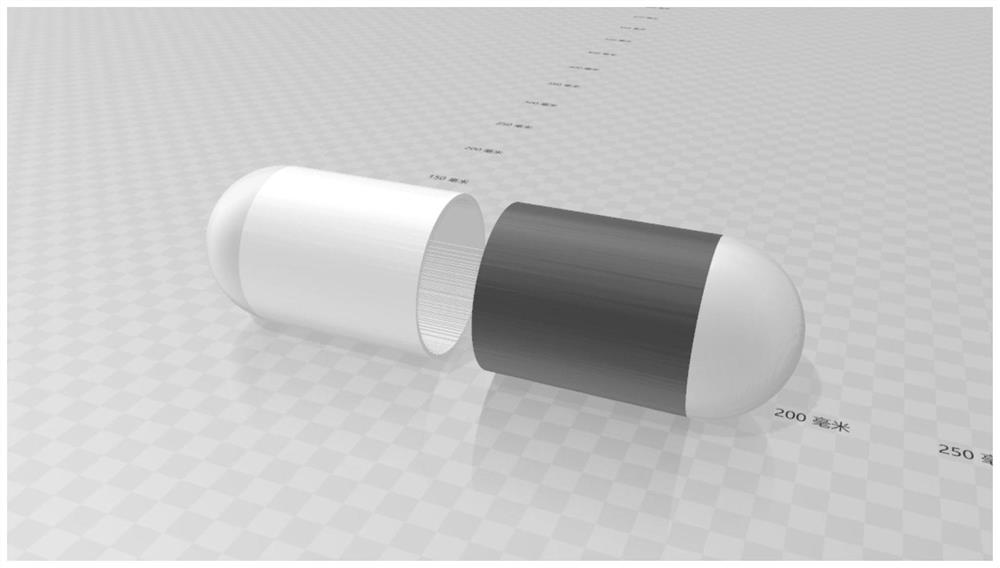

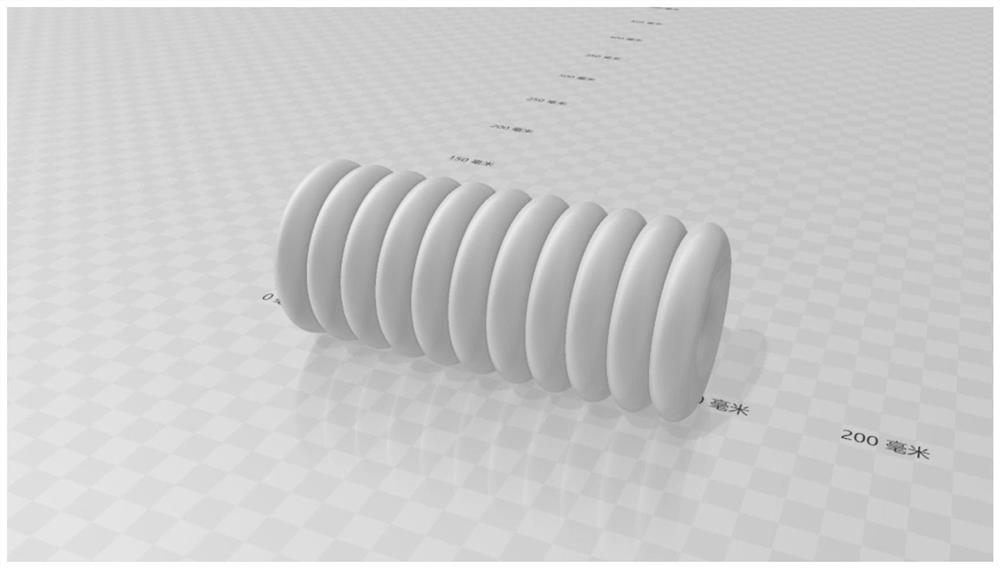

[0030] A scent sustained-release capsule, comprising composite microspheres 2 including several microsphere units, and a matching capsule shell 1 is arranged on the outside of the composite microspheres 2 . The composite microsphere 2 has a pore diameter of 10 nm, and the capsule shell 1 has a length of 200 mm; the composite microsphere 2 is a starch-β-cyclodextrin composite microsphere, and the capsule shell 1 is made of xanthan gum.

[0031] The preparation method of above-mentioned aroma slow-release capsules, comprises the following steps:

[0032] (1) Mix β-cyclodextrin and pretreated starch at a mass ratio of 2:1, then add deionized water 6 times the mass of pretreated starch, adjust the pH value to 10.2, and then add cross-linking aids at 20KV / cm and Perform pulse electric field treatment at 200Hz, centrifuge, wash and dry in sequence to obtain starch-β-cyclodextrin; the cross-linking aid is a mixture of chloroacetic acid solution and lanthanum chloride solution mixed b...

Embodiment 2

[0037] A scent sustained-release capsule, comprising composite microspheres 2 including several microsphere units, and a matching capsule shell 1 is arranged on the outside of the composite microspheres 2 . The pore diameter of the composite microsphere 2 is 40nm, and the length of the capsule shell 1 is 200mm; the composite microsphere 2 is a starch-β-cyclodextrin composite microsphere, and the material of the capsule shell 1 is xanthan gum.

[0038] The preparation method of above-mentioned aroma slow-release capsules, comprises the following steps:

[0039](1) Mix β-cyclodextrin and pretreated starch at a mass ratio of 3:1, then add deionized water 7 times the mass of pretreated starch, adjust the pH to 10.4, and then add cross-linking aids at 25KV / cm and Perform pulse electric field treatment at 240Hz, centrifuge, wash and dry in sequence to obtain starch-β-cyclodextrin; the cross-linking aid is a mixture of chloroacetic acid solution and lanthanum chloride solution mixed ...

Embodiment 3

[0044] A scent sustained-release capsule, comprising composite microspheres 2 including several microsphere units, and a matching capsule shell 1 is arranged on the outside of the composite microspheres 2 . The composite microsphere 2 has a pore diameter of 60 nm, and the capsule shell 1 has a length of 200 mm; the composite microsphere 2 is a starch-β-cyclodextrin composite microsphere, and the capsule shell 1 is made of xanthan gum.

[0045] The preparation method of above-mentioned aroma slow-release capsules, comprises the following steps:

[0046] (1) Mix β-cyclodextrin and pretreated starch at a mass ratio of 3:1, then add deionized water 8 times the mass of pretreated starch, adjust the pH value to 10.5, and then add cross-linking aids at 30KV / cm and Perform pulse electric field treatment at 250Hz, centrifuge, wash and dry in sequence to obtain starch-β-cyclodextrin; the cross-linking aid is a mixture of chloroacetic acid solution and lanthanum chloride solution mixed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com