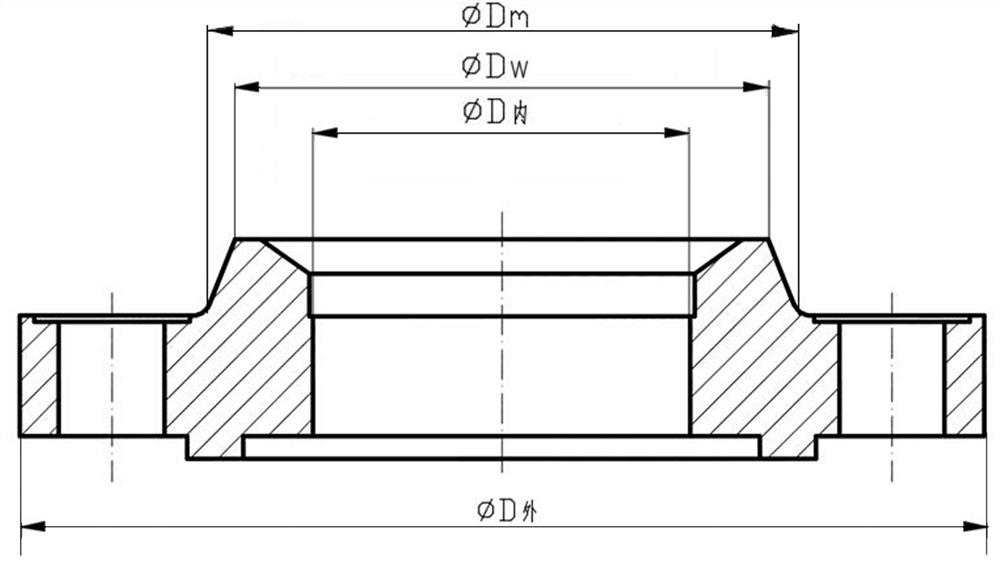

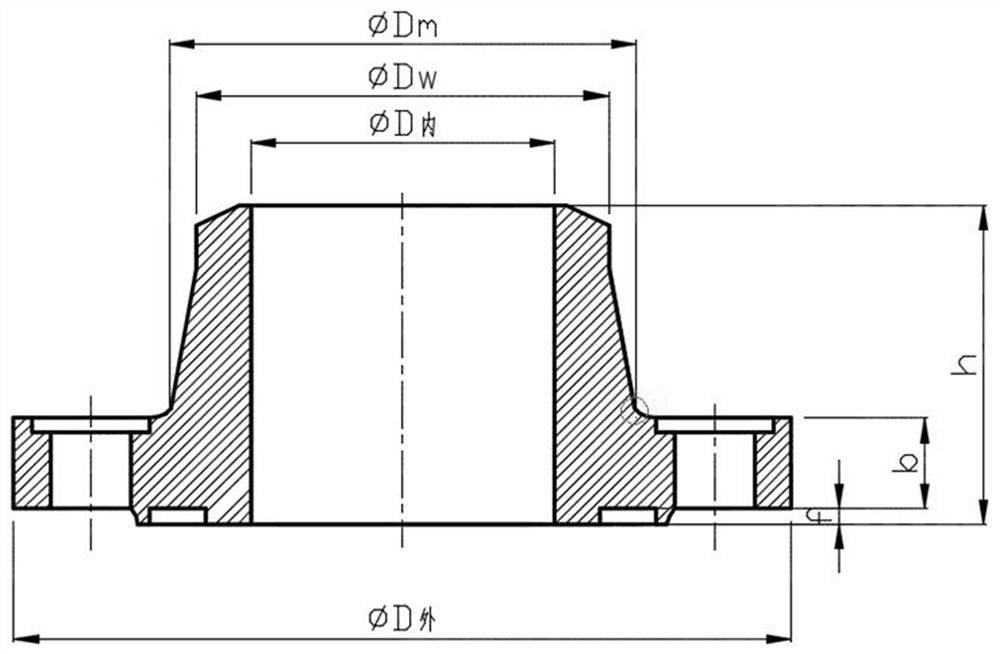

Closed large-sized copper-nickel alloy BFe30-1-1 flange forming die and machining method

A copper-nickel alloy and forming die technology, which is applied in the field of processing and manufacturing, can solve the problems of low material utilization rate and high production cost, and achieve the effect of reducing the extrusion process and shortening the processing period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

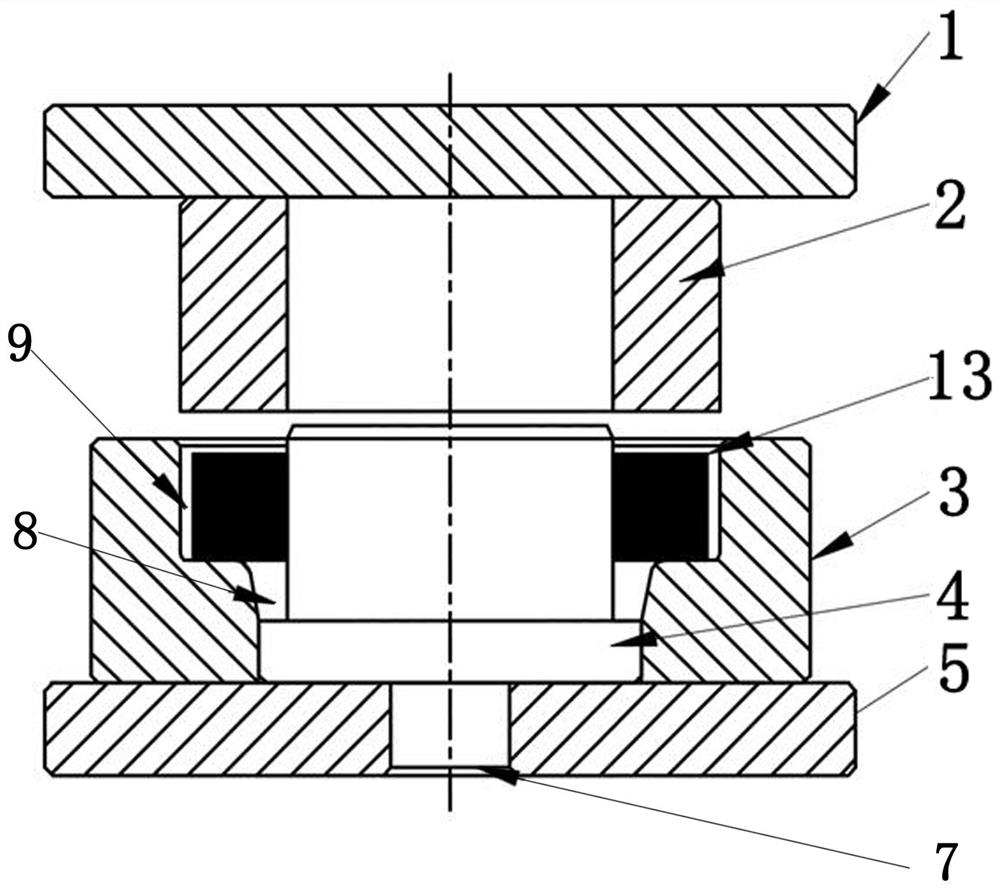

Method used

Image

Examples

Embodiment 1

[0053] The present invention is applied to the Type II DN200 flange in the Q / 725-1123-2000 standard. The single-piece blanking specification is changed from Φ360 / Φ205*90mm to Φ140*240mm, and the single-piece blanking weight is reduced from 56.75kg to 35.9kg. The utilization rate improved to 61.9% from the previous 39.1%.

Embodiment 2

[0055] The invention has been applied to the I-type DN200 copper-nickel alloy BFe30-1-1 flange in Q / 725-1123-2000.

[0056] The copper-nickel alloy BFe30-1-1 flange is pressed and formed with a closed flange forming mold, and the single-piece blanking is changed from Φ360 / Φ185*102mm with a single weight of 70.04kg to Φ245*98mm with a single weight of 41.1kg, and the material utilization rate has changed from before 34% increased to 58%.

Embodiment 3

[0058] The present invention is applied to the I-type DN150 flange in the Q / 725-1123-2000 standard. The single-piece blanking specification is changed from Φ290 / Φ132*86mm to Φ260 / Φ137×68, and the single-piece blanking weight is reduced from 41.28kg to 23.91kg. , The material utilization rate increased from the previous 34.4% to 59.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com