Mechanical equipment for welding connecting rod

A technology of mechanical equipment and connecting rod, applied in the field of connecting rod welding, can solve the problems of reducing the life of the welding head, reducing the toughness of the welding joint, and cooling the welding part, and achieves the effects of improving the welding efficiency, preventing the reduction of the toughness and softening the flame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

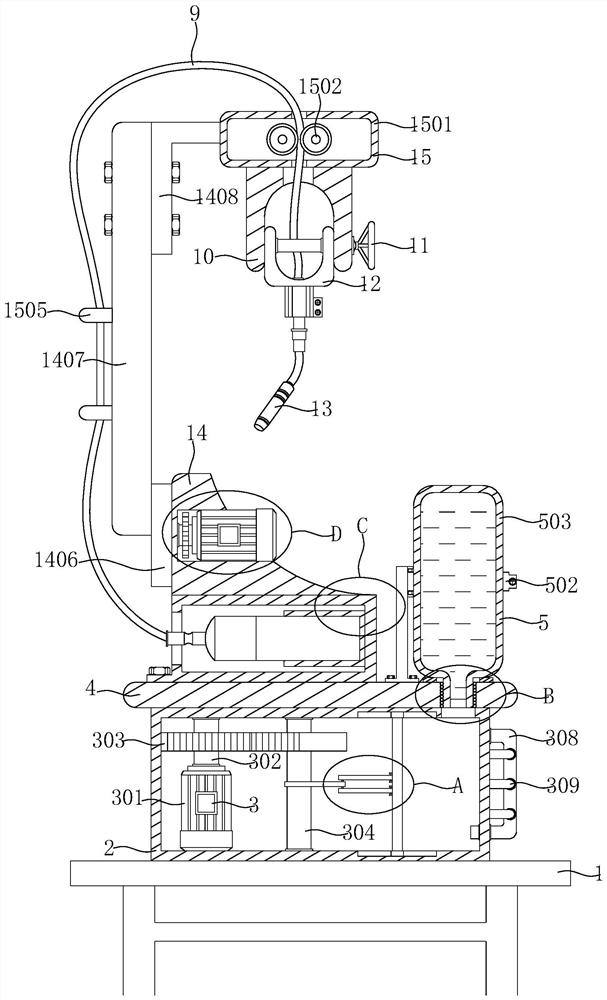

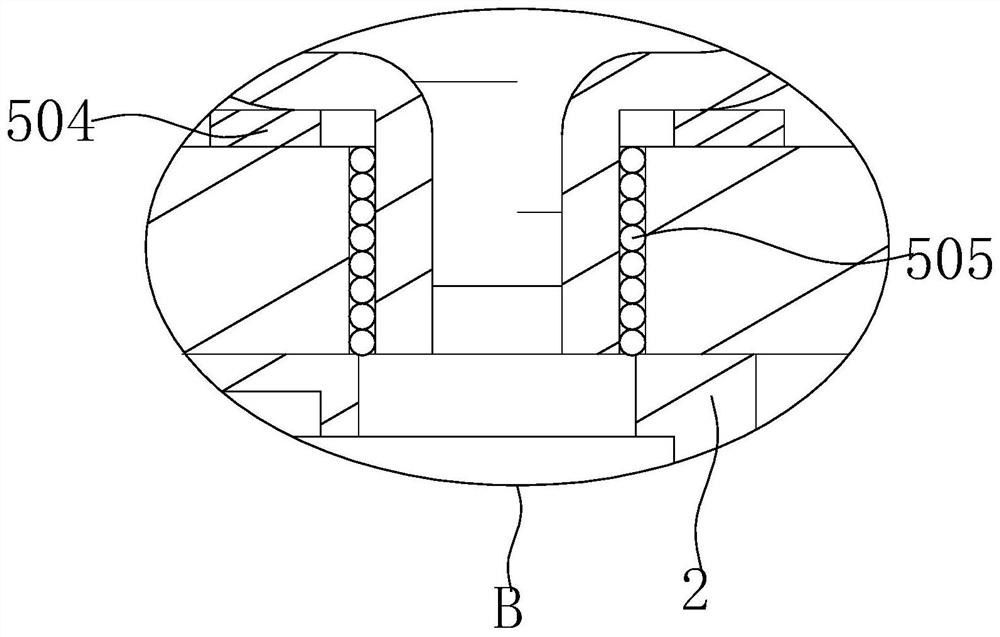

[0028] see Figure 1-8, the present invention provides a technical solution: a mechanical device for welding connecting rods, including a working platform 1, a working box 2 is fixedly installed on the top outer surface of the working platform 1, and a cooling mechanism 3 is arranged inside the working box 2, The top outer surface of the work box 2 is provided with a load-bearing plate 4, the water-adding mechanism 5 is arranged on the load-bearing plate 4, the top outer surface of the load-bearing plate 4 is fixedly installed with a protective cover 6, and the inner wall of one side of the protective cover 6 is fixedly connected with a fixed sleeve 7. The inside of the fixed sleeve 7 is provided with a MAPP bottle 8, one end of the MAPP bottle 8 is fixedly connected with an explosion-proof hose 9 and communicates with the inside, the top of the working platform 1 is provided with a first arcuate plate 10, and the first arcuate plate 10 is provided with a There is an opening, ...

Embodiment 2

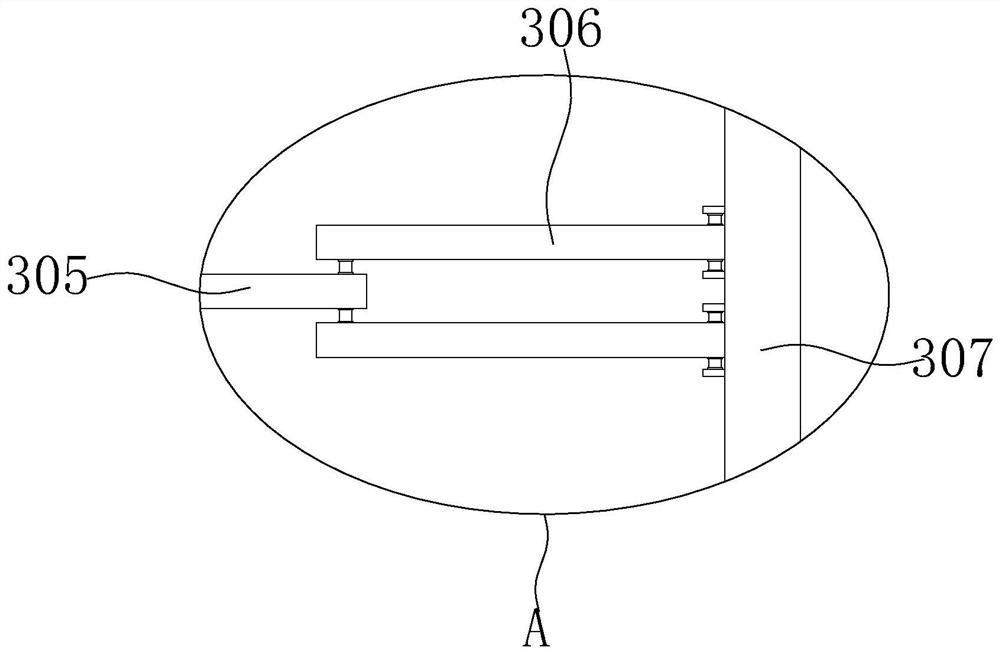

[0030] see Figure 1-8 , on the basis of Embodiment 1, the cooling mechanism 3 includes a first motor 301, a coarse rotating rod 302, a first driving gear 303, a long rotating rod 304, an eccentric wheel 305, a hinged frame 306, a sealing plate 307, and a U-shaped tube 308 And the L-shaped pipe 309, the inner top of the working box 2 is rotatably equipped with a coarse rotating rod 302, the inner bottom of the working box 2 is fixedly installed with a first motor 301, and the output shaft of the first motor 301 is connected with the coarse rotating rod 302 through a coupling. One end of the thick rotating rod 302 is fixedly connected with the first driving gear 303 on the fixed sleeve, and the inner bottom of the working box 2 is rotatably equipped with a long rotating rod 304, and the fixed sleeve on the long rotating rod 304 is provided with the first group of incomplete gears and The eccentric wheel 305, the first set of incomplete gears mesh with the first driving gear 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com