Compressive strain monitoring sensor for road structure, as well as manufacturing method and device

A technology for monitoring sensors and manufacturing methods, which can be applied to measurement devices, electromagnetic measurement devices, and electrical/magnetic solid deformation measurement, etc., can solve the problems of unstable contact electrical signals, complex production processes, and low production efficiency, and achieve significant economic benefits. and the society, the easy availability of manufacturing materials, and the simplicity of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

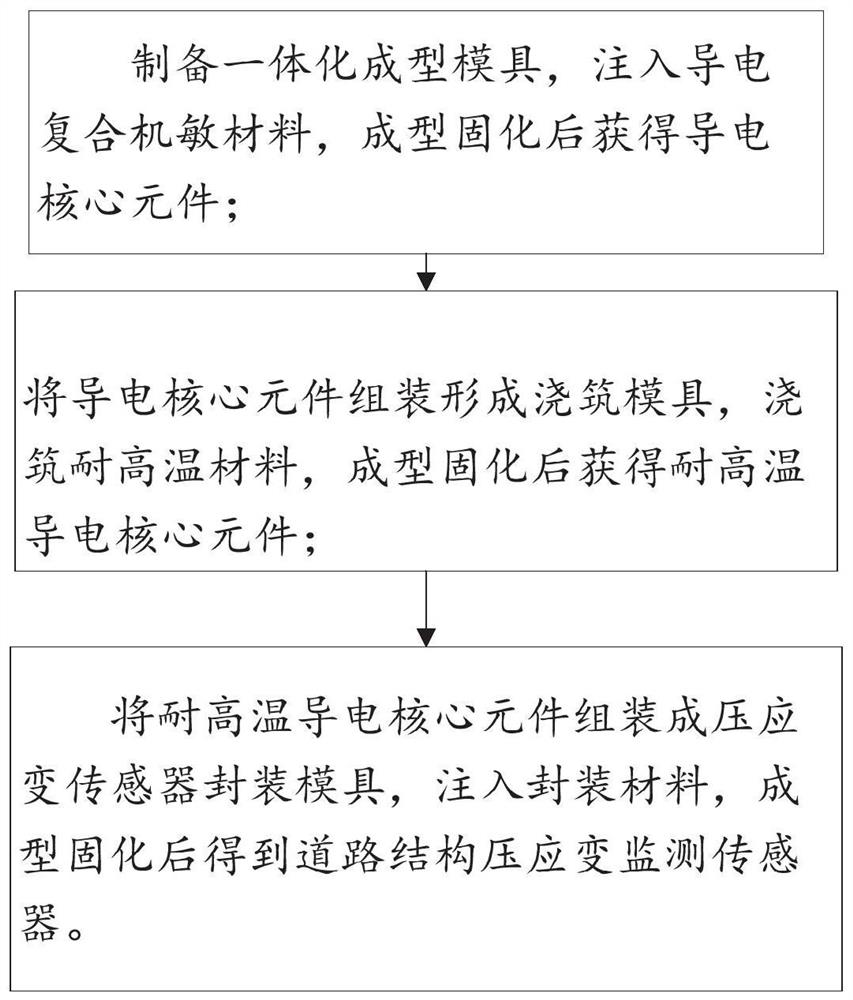

[0033] Such as figure 1 As shown, the present disclosure provides a method for manufacturing a road structure compressive strain monitoring sensor, the steps comprising:

[0034] Prepare an integrated molding mold, inject conductive composite smart materials, and obtain conductive core components after molding and curing;

[0035] Assemble the conductive core components to form a casting mold, pour high-temperature resistant materials, and obtain high-temperature resistant conductive core components after molding and curing;

[0036] The high-temperature-resistant conductive core components are assembled into a compressive strain sensor packaging mold, the packaging material is injected, and the road structure compressive strain monitoring sensor is obtained after molding and curing.

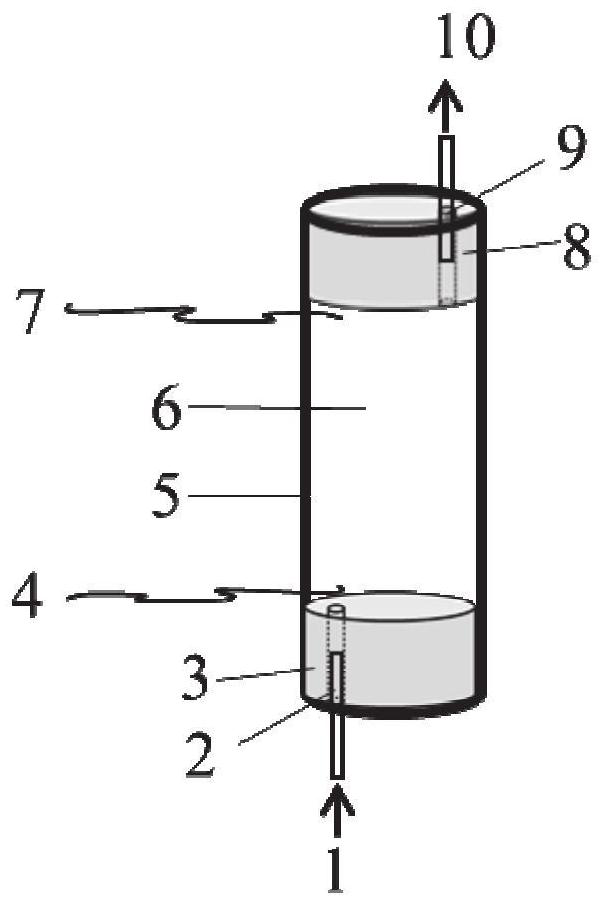

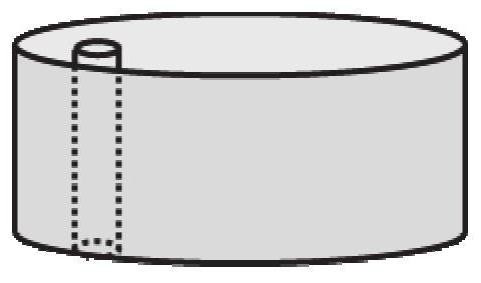

[0037] Further, the high-temperature-resistant material is epoxy resin, and the pouring mold is an epoxy column casting mold. The upper and lower ends of the epoxy column casting mold are respe...

Embodiment 2

[0049] The present disclosure provides a method for manufacturing a small compressive strain and compressive stress monitoring sensor for road structures, including:

[0050] (1) Cut a silicone tube with a length of 5cm and an inner diameter of 1cm, and clean the inside. Drill a hole at the corresponding position of the silicone tube, and insert the pre-embedded wire with the protective skin removed at both ends into the hole.

[0051] (2) Insert the lower end into the cap and the upper end of the outflow cap into the silicone tube, wherein the diameter of the cap is consistent with the inner diameter of the silicone tube. Insert the lower end injection conduit into the reserved aperture on one side of the lower end injection cap, and insert the upper end outflow conduit into the reserved aperture on the upper end outflow cap side. The wire should be tightly attached to the caps at both ends.

[0052] (3) Seal the hole reserved for the cap plug and the hole where the wire is...

Embodiment 3

[0060] The present disclosure provides a road structure compressive strain monitoring sensor, which is manufactured by adopting the manufacturing method of a road structure compressive strain monitoring sensor as described in the above-mentioned embodiments, including a core element of a conductive composite smart material, an epoxy column and an outer packaging layer, The top and bottom of the core element of the conductive composite smart material are equipped with epoxy columns, and the sides of the conductive composite smart material are wrapped with an outer packaging layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com