A kind of sintering method glass ceramic colorant

A glass ceramic and colorant technology, which is applied in glass molding, glass manufacturing equipment, dental preparations, etc., can solve the problems of decreased mechanical properties, increased production costs, fuel consumption, etc., and achieves excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

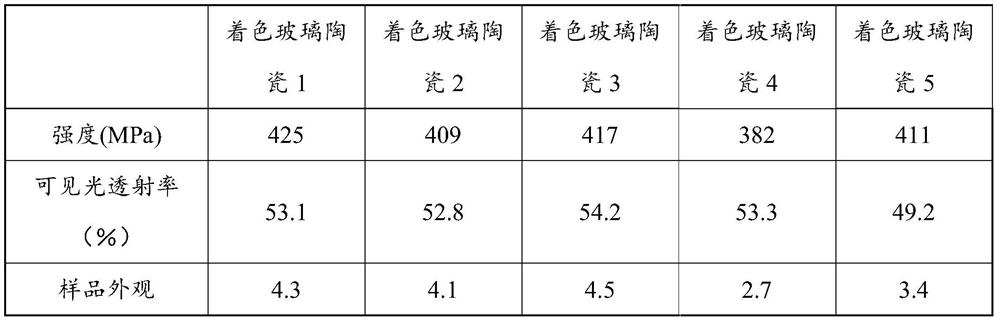

Examples

Embodiment 1

[0022] Preparation of Colorant 1

[0023] Weigh 0.12 moles of Er(NO 3 ) 3 , 0.04 mol Pr(NO 3 ) 3 , 0.07 mol Al (NO 3 ) 3 , 0.06 mol Fe(NO 3 ) 3 and 0.6mol EDTA, add it to 1L ethanol solvent, stir well. Then, a small amount of formic acid was added thereto so that the concentration of formic acid was 3 wt %, and a colorant 1 was obtained.

Embodiment 2

[0025] Preparation of Colorant 2

[0026] Colorant 2 was prepared in the same manner as Example 1, except that methanol was used as the solvent.

Embodiment 3

[0028] Preparation of Colorant 3

[0029] Colorant 3 was prepared in the same manner as Example 1, except that 0.27 moles of Er(NO 3 ) 3 , 0.02 mol Pr(NO 3 ) 3 and 0.01 mol Fe(NO 3 ) 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com