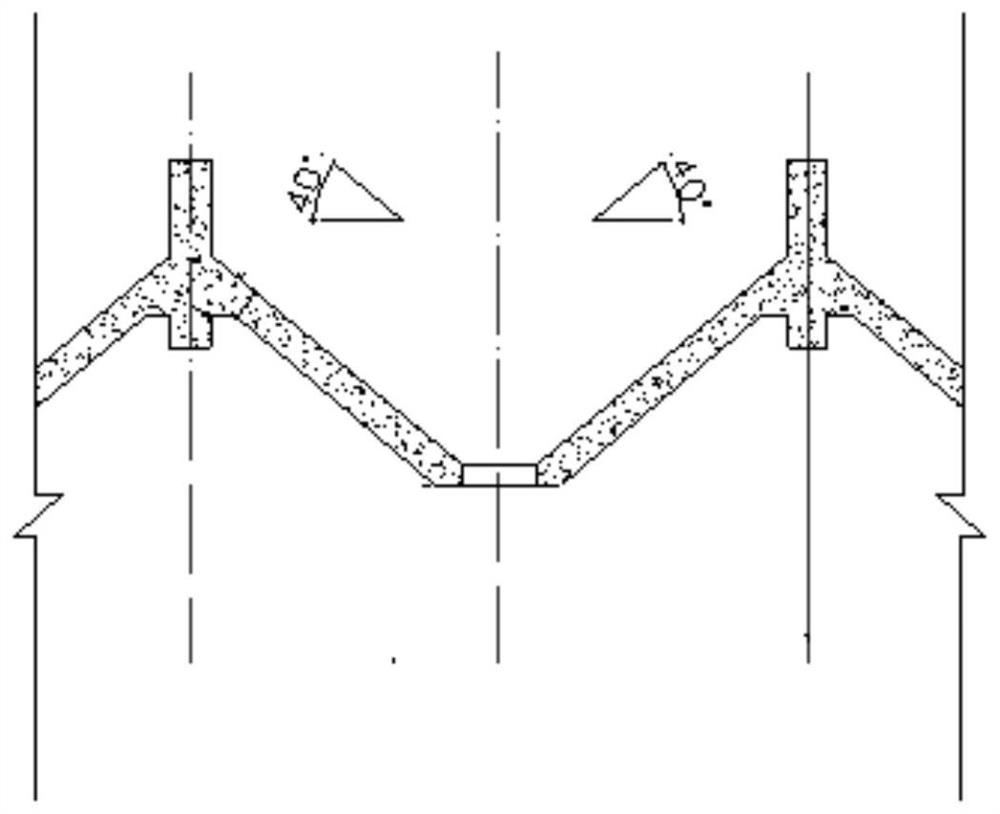

Square concrete funnel formwork supporting structure and construction method

A concrete and formwork technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, building structure, etc., can solve the problems of deformation, insufficient supporting strength of the lower formwork, etc. Deformation, reduce erection time, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

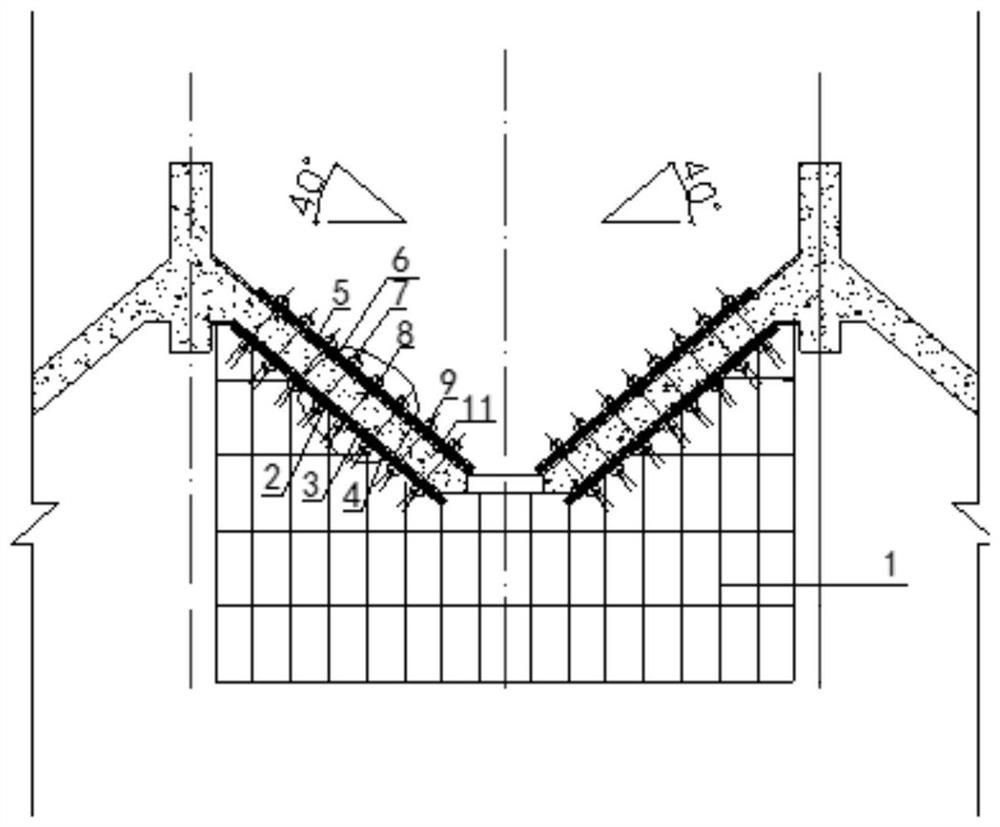

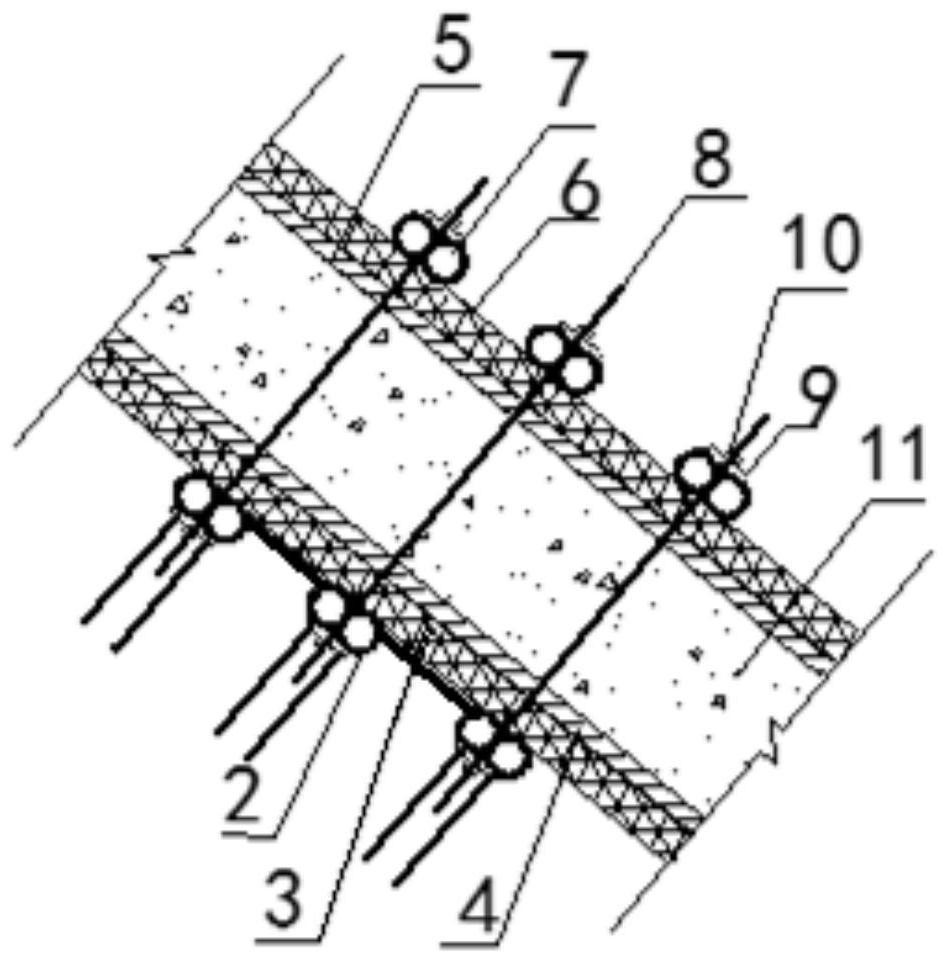

[0030] Such as Figure 1-Figure 6 As shown, a square concrete funnel formwork support structure includes upper formwork 5, lower formwork 4, last corrugation 6, next corrugation 3, opposite pull screw 8, upper main corrugation 7, lower main corrugation 2, the lower main corrugation The main flute 2 is composed of two trusses. The truss is a planar frame structure formed by welding the upper chord 2.1, the lower chord 2.2 and the web 2.3. The upper chord 2.1 is a steel pipe with the same specification as the upper main flute 7. , the upper chord 2.1 is welded and connected through the connecting rod 2.4 between the two trusses;

[0031] When the formwork is supported, several lower main flutes 2 are arranged side by side at the bottom of the lower formwork 4 and the next lower flute 3, the length direction of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com