Cast-in-place ultra-high performance concrete (UHPC) combined shielding shell

A combined shielding and ultra-high-performance technology, which is applied in the direction of protective buildings/shelters, building types, buildings, etc., can solve the problems of difficult construction, high construction and operation and maintenance costs, and long construction period, so as to maintain the overall Stress performance, reduce damage, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

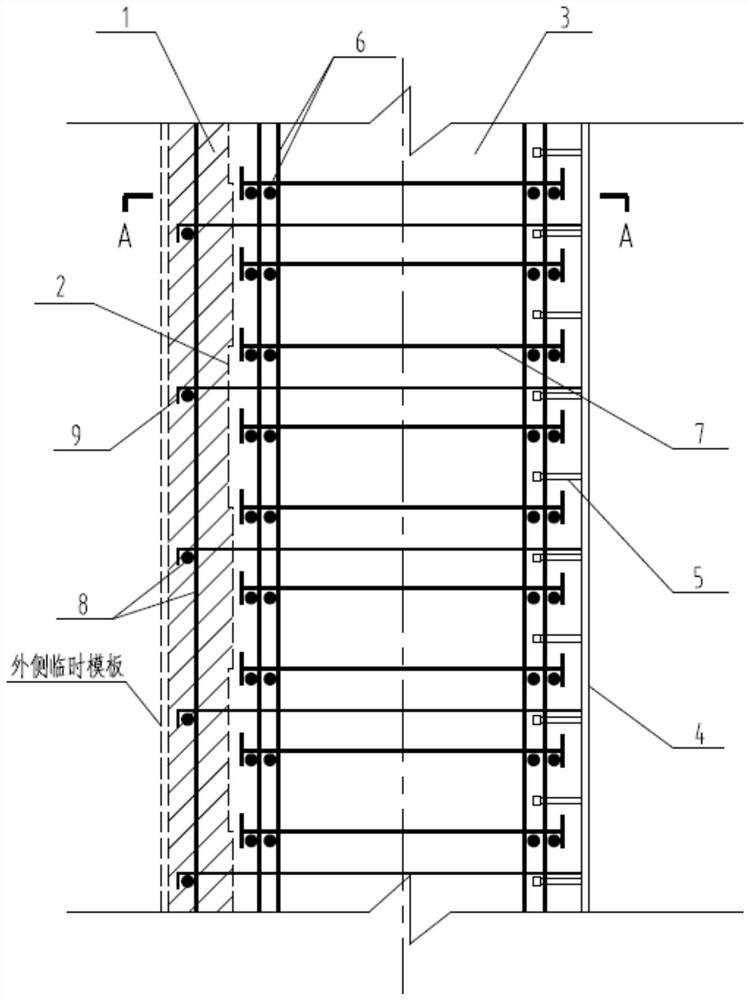

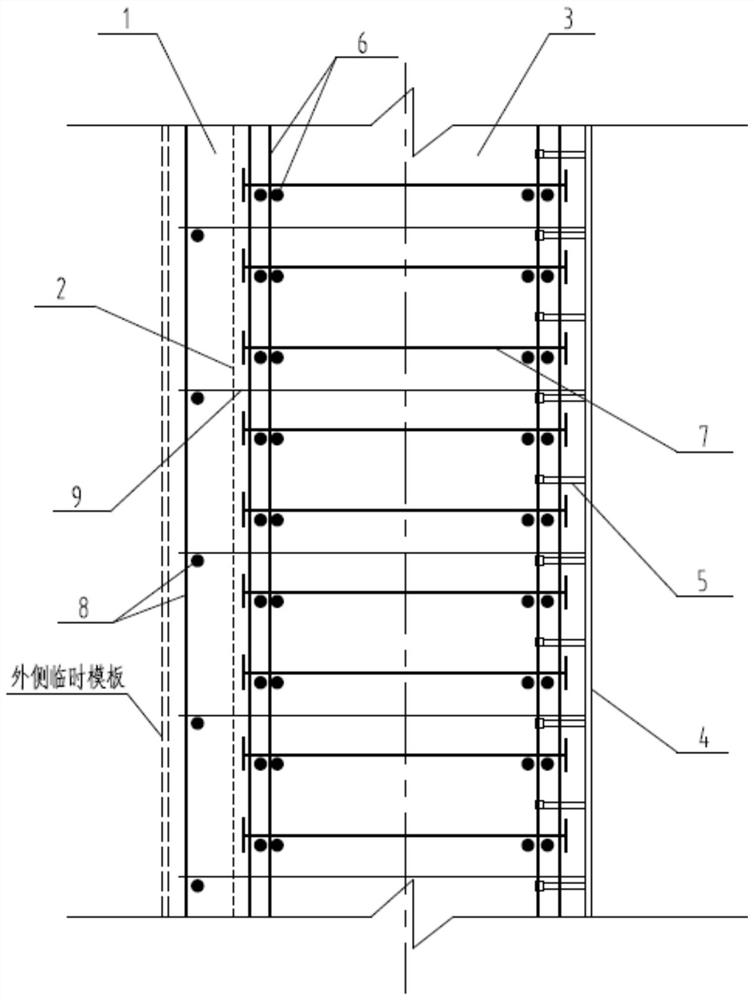

[0022] Such as figure 1 with figure 2 As shown, the cast-in-place combined shielding shell of the present invention includes a UHPC layer 1, a rigid non-disassembly formwork 2, an RC layer 3 and a back crack-proof panel 4; the rigid non-disassembly formwork 2 is arranged on the UHPC layer 1 and the RC layer 3, it is used as the separation zone between UHPC layer 1 and RC layer 3 during construction; The rooms are connected to each other through connectors 9 (i.e. civil structural construction measures).

[0023] The stud 5 is welded on the back anti-crack panel 4 for connecting the back anti-crack panel 5 and the RC layer 3; the stud 5 can be made of high-strength carbon steel or low-alloy steel.

[0024] The UHPC layer 1 is poured with ultra-high performance concrete, and the UHPC layer 1 is equipped with structural steel bars 8 .

[0025] The RC layer 3 is poured with ordinary strength concrete, and the RC layer 3 is equipped with RC layer main reinforcement 6 and RC lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com