Double-rotor internal combustion engine

A technology of internal combustion engine and double rotor, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of difficult sealing treatment, poor processability of the crankshaft of multi-cylinder internal combustion engine, limited volume of piston internal combustion engine, etc., and achieve simple processing and assembly, High conversion efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

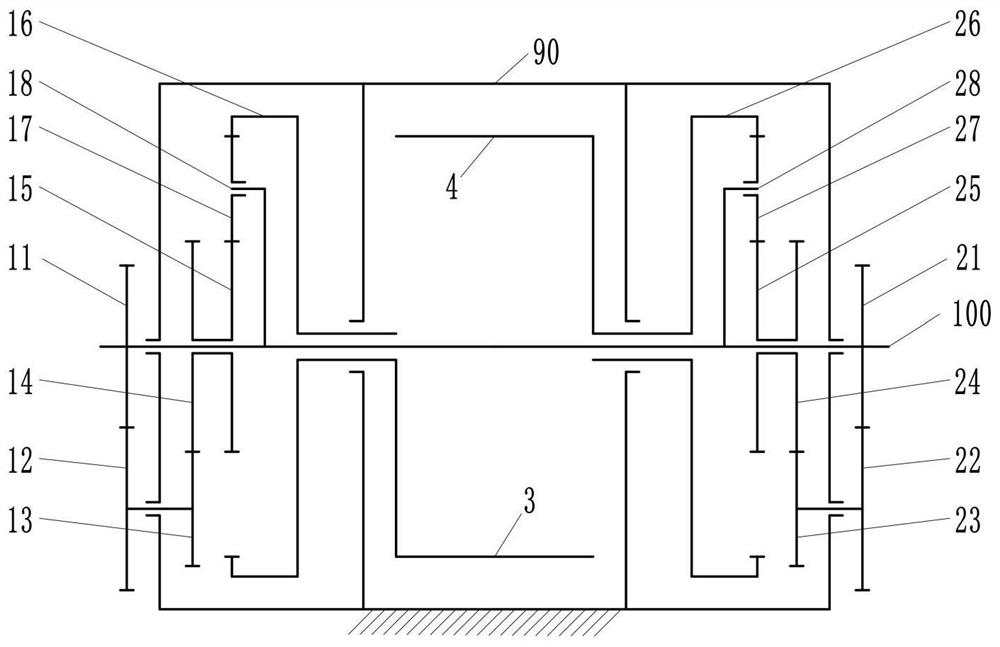

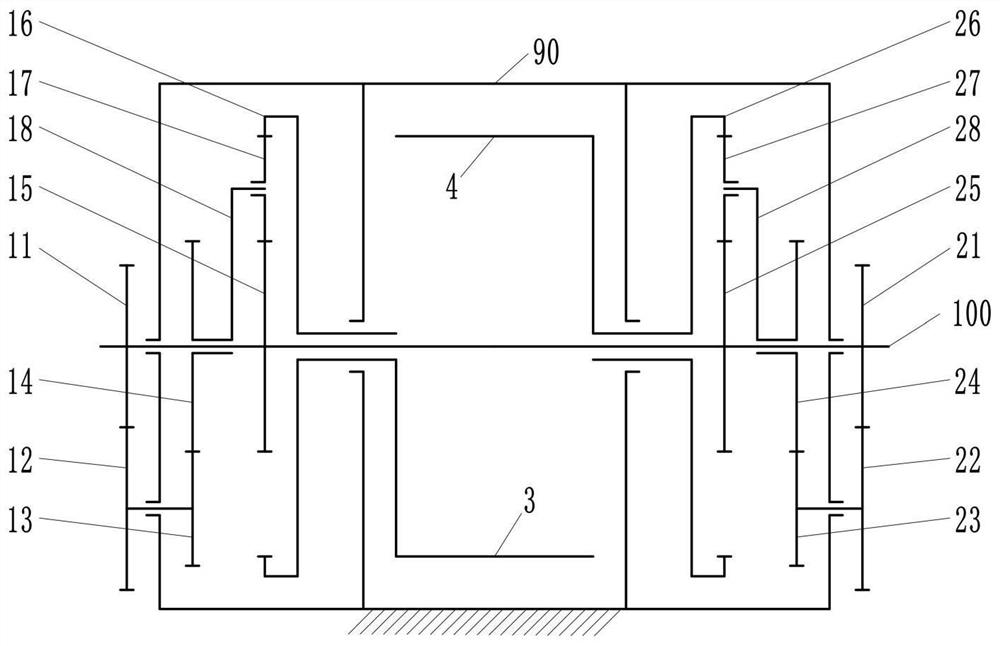

[0144] refer to Figure 1 to Figure 15 , the dual rotor internal combustion engine that embodiment 1 provides comprises:

[0145] Left short shaft 10, left first gear 11, left second gear 12, left third gear 13, left fourth gear 14, left fifth gear 15, left sixth gear 16, three left planetary wheels 17, left planetary frame 18;

[0146] Right short shaft 20, right first gear 21, right second gear 22, right third gear 23, right fourth gear 24, right fifth gear 25, right sixth gear 26, three right planetary wheels 27, right planetary Rack 28;

[0147] Left support body 30, left blade 31, left counterweight 35;

[0148] Right support body 40, right blade 41, right counterweight 45;

[0149] Left sealing plate 50, left supporting cover 51, left sealing cover 52;

[0150] Right sealing plate 60, right supporting cover 61, right sealing cover 62;

[0151] Left cam 70, left air channel 71, left valve 72, left ejector rod 73, left spring 74;

[0152] Right cam 80, right air cha...

Embodiment 2

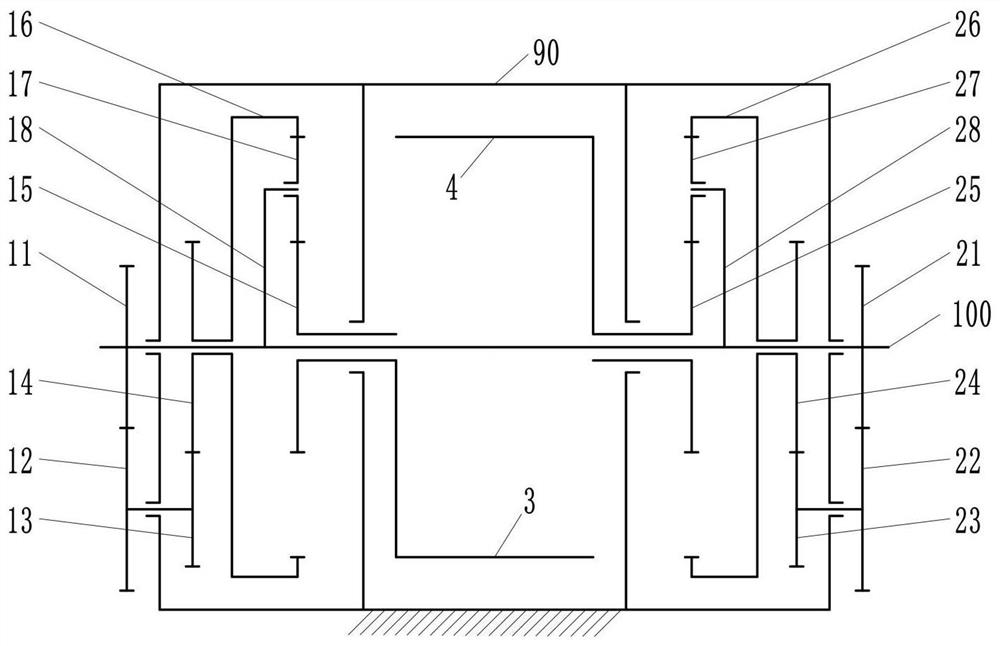

[0208] Embodiment 2 is a derivative solution of Embodiment 1. All the parts contained in Embodiment 1 can find their corresponding parts in Embodiment 2, and the connection relationship of these parts remains unchanged. The twin rotor internal combustion engine that embodiment 2 provides, its concrete structure is as Figures 21 to 23shown. Wherein, the position and connection relationship of the first gear, the second gear, the planetary gear, the first bearing, the second bearing, the sixth bearing, and the seventh bearing that are not shown can refer to the parts with the same name in the first embodiment.

[0209] Compared with embodiment 1, the components of embodiment 2 have more second spark plug 93, second fuel injector 94; left second cam 75, left second air channel 76, left second valve 77, left second top Rod 78, left second spring 79; Right second cam 85, right second air passage 86, right second air valve 87, right second push rod 88, right second spring 89. Sim...

Embodiment 3

[0213] refer to Figure 24 to Figure 30 , the dual-rotor internal combustion engine provided in Embodiment 3 includes:

[0214] Left short shaft 10, left first gear 11, left second gear 12, left third gear 13, left fourth gear 14, left fifth gear 15, left sixth gear 16, three left planetary wheels 17, left planetary Frame 18, left pad 19;

[0215] Right short shaft 20, right first gear 21, right second gear 22, right third gear 23, right fourth gear 24, right fifth gear 25, right sixth gear 26, three right planetary wheels 27, right planetary Frame 28, right block 29;

[0216] Left support body 30, left first blade 31, left second blade 32;

[0217] Right support body 40, right first blade 41, right second blade 42;

[0218] Left sealing plate 50, left supporting cover 51, left sealing cover 52;

[0219] Right sealing plate 60, right supporting cover 61, right sealing cover 62;

[0220] Left cam 70, left first air passage 71, left first air valve 72, left first push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com