MgB2 superconducting cable joint and preparation and connection method thereof

A superconducting cable and superconducting technology, which are applied in the manufacturing of contacts, connecting contact materials, connecting/disconnecting of connecting devices, etc., can solve problems such as cable length limitation, reduce AC loss, simple manufacturing method, low AC The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The number of strands of the two superconducting cables to be connected is 3 strands, and all of them are superconducting strands. The specific implementation process is:

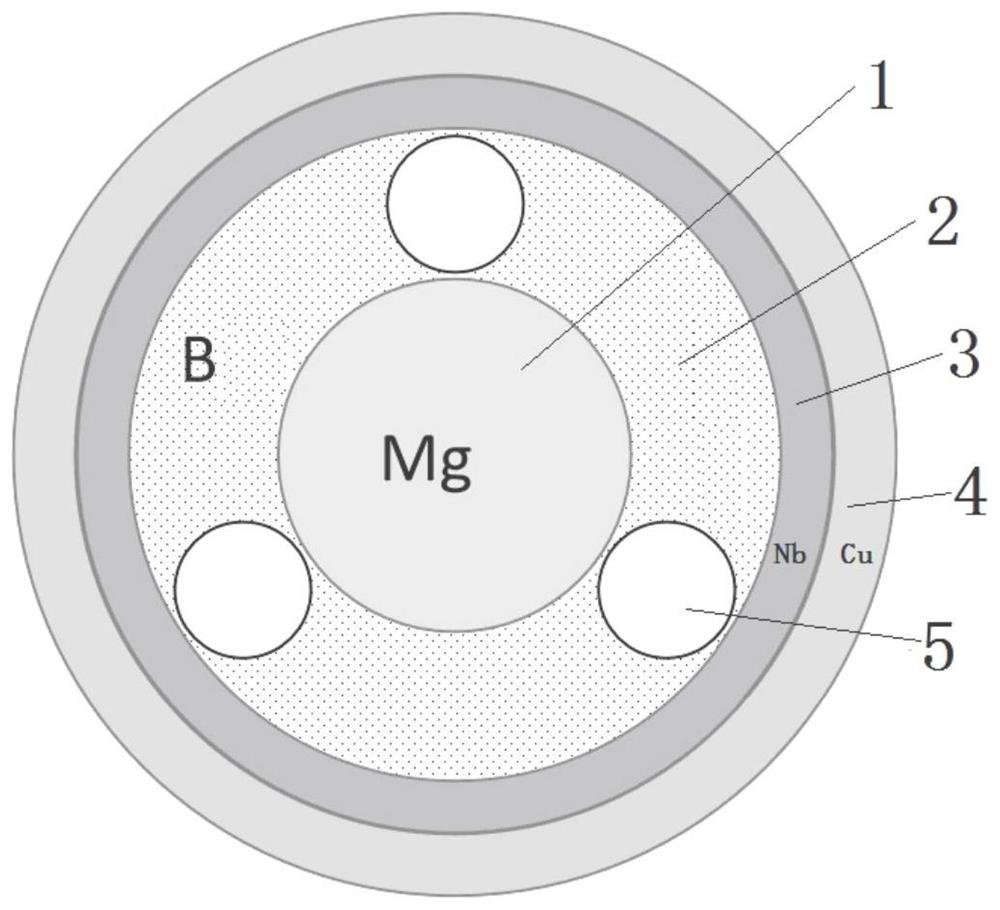

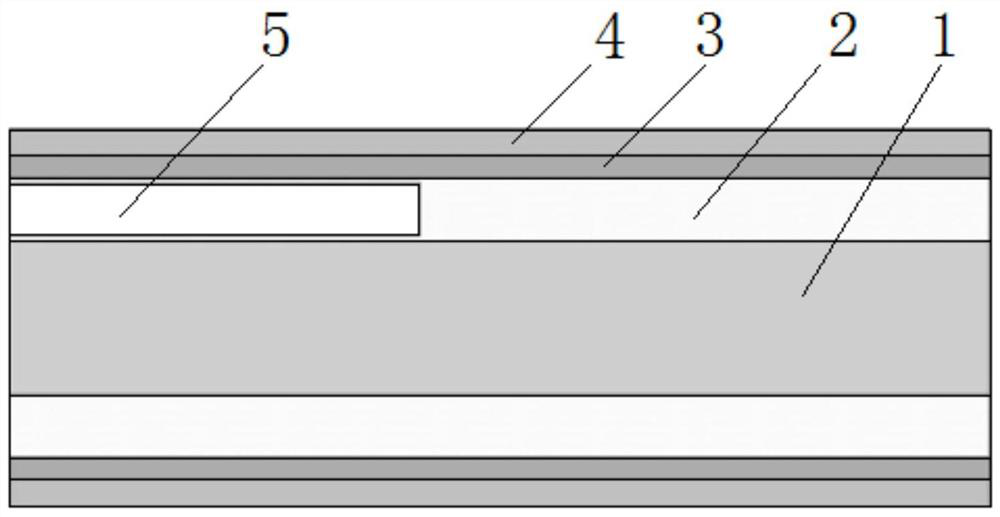

[0027] (1) In a vacuum glove box, fix the Mg rod in the middle of the Nb / Cu composite tube, and put the amorphous B powder into the gap between the Mg rod or the outside of the Mg tube and the Nb / Cu composite tube to obtain a Composite body; the atomic ratio of the Mg rod to the loaded B powder is 0.48-1. The outermost layer of the primary complex is Cu;

[0028] (2) Using 30% of the pass processing amount, the primary complex is drawn in multiple passes to a diameter of Φ5mm, and a 100mm length is cut off as a preform for making a superconducting joint. The specifications of each component in the cross section of the preform are determined by the center The areas outward are: the Mg area in the central area occupies the central area Φ2mm, the ring structure occupied by the B ring area is about Φ3....

Embodiment 2

[0037] The strands of the two superconducting cables to be connected are 3 strands and 4 strands respectively, and all of them are superconducting strands. The specific implementation process is:

[0038] (1) In a vacuum glove box, fix the Mg rod in the middle of the Nb / Cu composite tube, and put the amorphous B powder into the niobium-copper composite tube with the Mg rod in the middle to obtain a primary composite; the Mg rod and the filling The atomic ratio of the B powder is 0.48-1. The outermost layer of the primary complex is Cu;

[0039] (2) Using 20% of the pass processing amount, the primary complex is drawn in multiple passes to a diameter of Φ20mm, and the length of 200mm is intercepted as a preform for making a superconducting joint. The specifications of each component in the cross section of the preform are given by Outward from the central area are: the central area occupied by the Mg area is Φ8mm, the ring structure occupied by the B ring area is about Φ14×...

Embodiment 3

[0048] The number of strands of the two superconducting cables to be connected is 7 strands, and its structure is that 6 superconducting strands are evenly surrounded by 1 copper wire. The specific implementation process is:

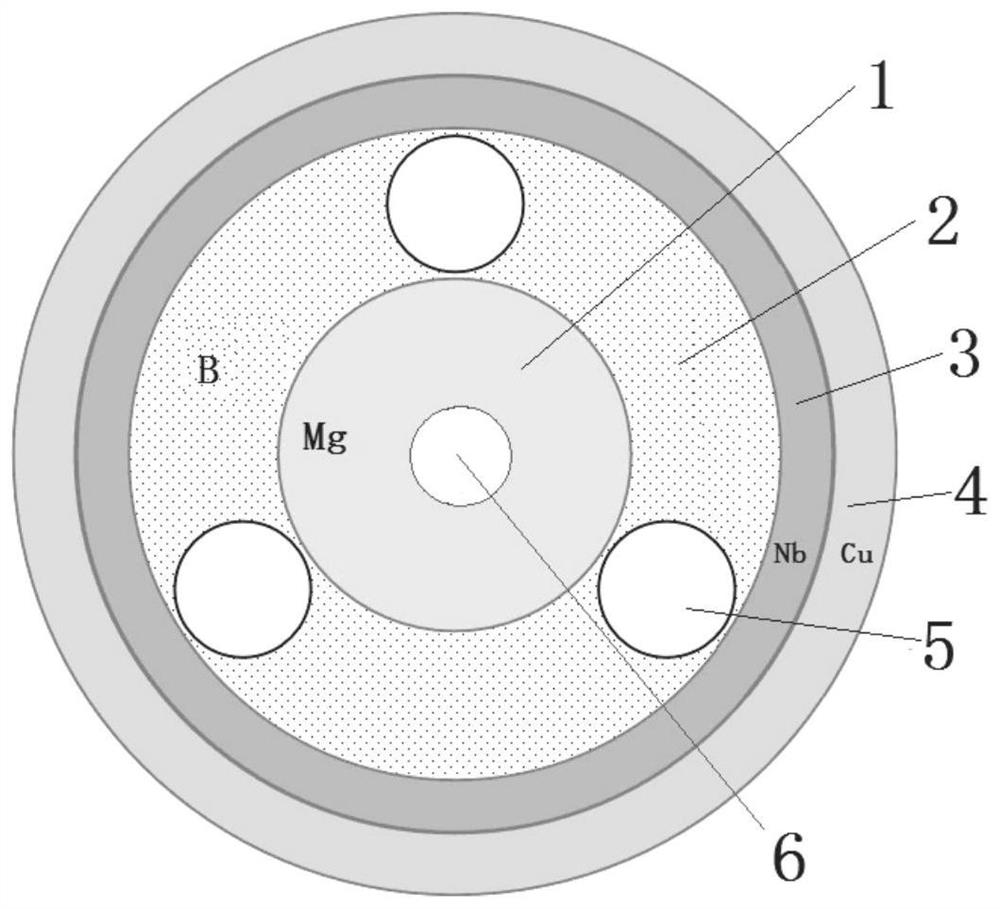

[0049] (1) In the vacuum glove box, the Mg tube is fixed in the middle of the Nb / Cu composite tube, and the amorphous B powder is packed into the gap between the outside of the Mg tube and the Nb / Cu composite tube to obtain a primary complex; the Mg tube The atomic ratio to the loaded B powder is 0.48-1. The outermost layer of the primary complex is Cu;

[0050] (2) Using 10% of the pass processing amount, the primary complex is swaged or drawn to a diameter of Φ16mm, and a 100mm length is cut off as a preform for making a superconducting joint. The specifications to the outside are: the central area occupied by the Mg tube is a ring structure of about Φ8×4mm, the area occupied by the B ring area is about Φ12×8mm, and the area occupied by the Nb ring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com