Method for realizing multi-axis control of industrial robot based on DSP+FPGA servo

An industrial robot and multi-axis control technology, applied in motor control, motor generator control, AC motor control, etc., can solve the problems of limited PWM peripherals and ADC peripherals, achieve fast current control response, improve control performance, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

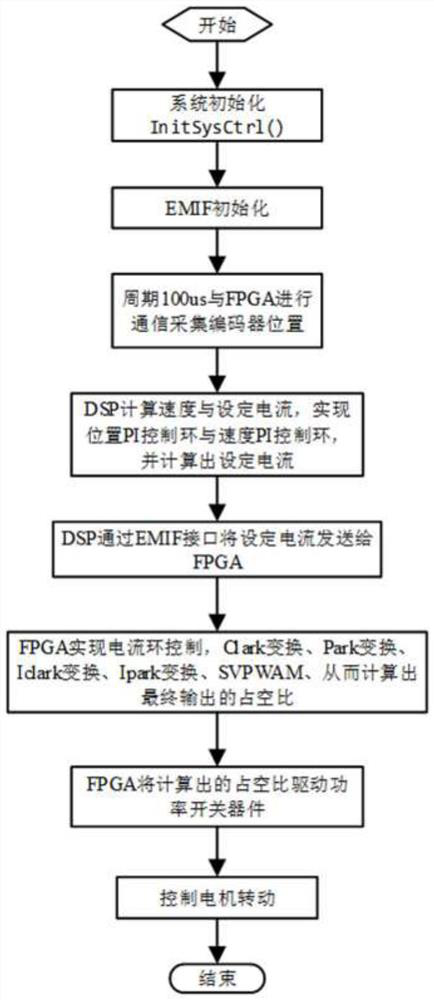

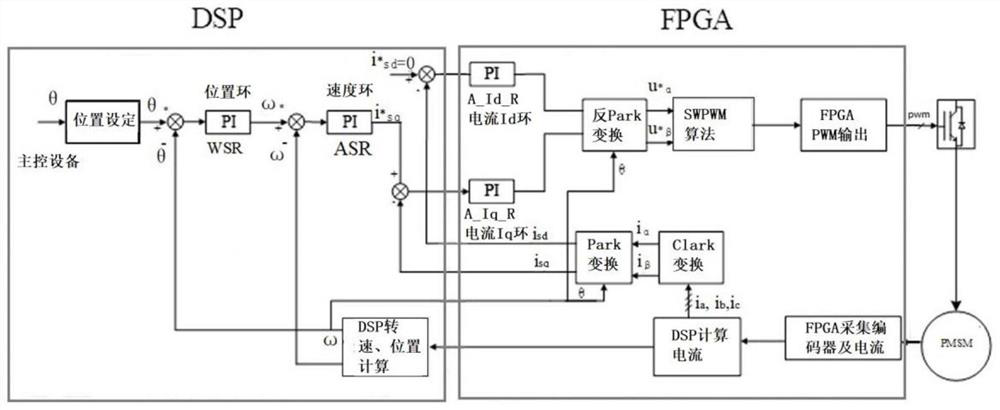

[0045] combined with figure 1 and figure 2 As shown, a method for realizing multi-axis control of industrial robots based on DSP+FPGA servo, including FPGA, DSP and servo drive circuit, including:

[0046] Step S100: First, perform system initialization and EMIF communication interface initialization;

[0047] Set the cycle of DSP and FPGA to communicate and collect current and encoder position to 100us;

[0048] FPGA collects encoder data, sends encoder data to DSP through EMIF interface, FPGA generates clock signal, typical clock cycle is 50ns, to collect current of current sampling chip, the data returned by current sampling chip is 16-bit digital signal current data to DSP;

[0049]FPGA uses the encoder protocol to collect encoder data. The encoder protocol includes commands to read multi-turn, read single-turn, read full data, read encoder faults, and clear fault alarms; encoder data includes single lap data, multi-turn data, position signal and fault alarm.

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com