Anesthetic equipment capable of automatically switching anesthetic gas and oxygen

An automatic switching, anesthetic gas technology, applied in breathing masks, respirators, etc., can solve the problems of emergency rescue, deepening of anesthesia, and aggravation of respiratory arrest for patients with unfavorable respiratory arrest, reducing rescue steps and having a simple structure. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

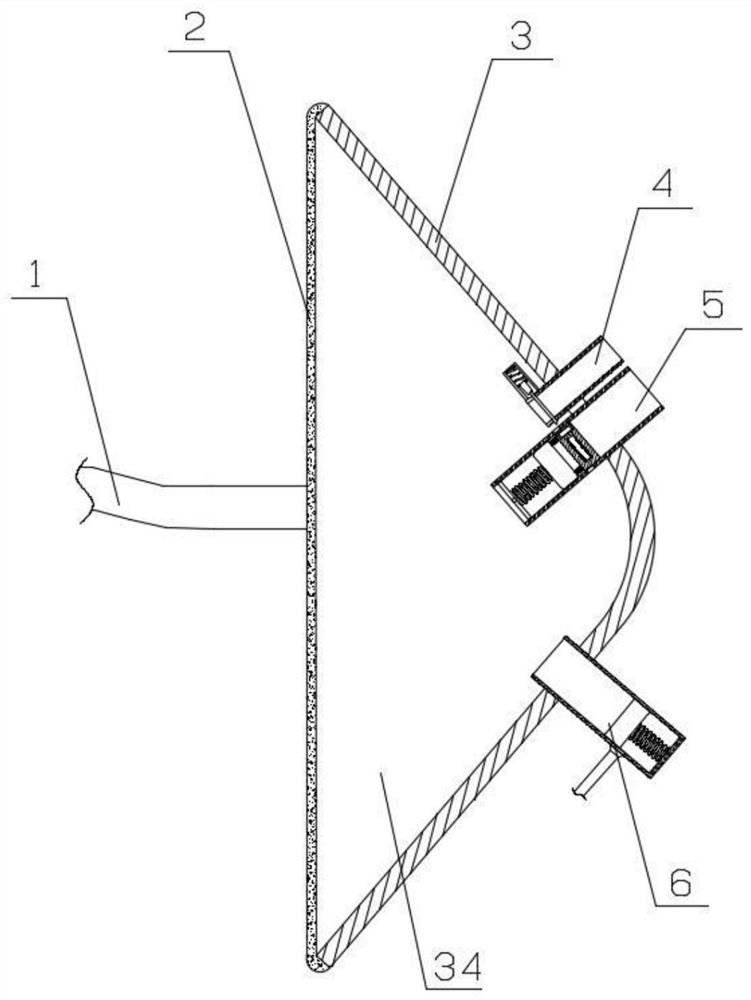

[0028] Such as figure 1 As shown, the main body of this embodiment is a breathing mask 3, and the breathing mask 3 is used to form a breathing zone 34 between the back of the patient's face and the patient's nose and mouth. In order to ensure the sealing of the breathing area 34 and prevent the anesthesia gas passing into the breathing area 34 and the components of the anesthetic gas in the exhalation of the patient from escaping and diffusing from the breathing area 34, the breathing mask 3 in this embodiment is also provided with an elastic fixing belt 1 and sealing strip 2. The breathing mask 3 is buckled and fixed on the patient's head through the elastic fixing belt 1 to avoid falling off, and the sealing strip 2 is used to maintain the isolation state of the breathing zone 34 from the outside atmosphere.

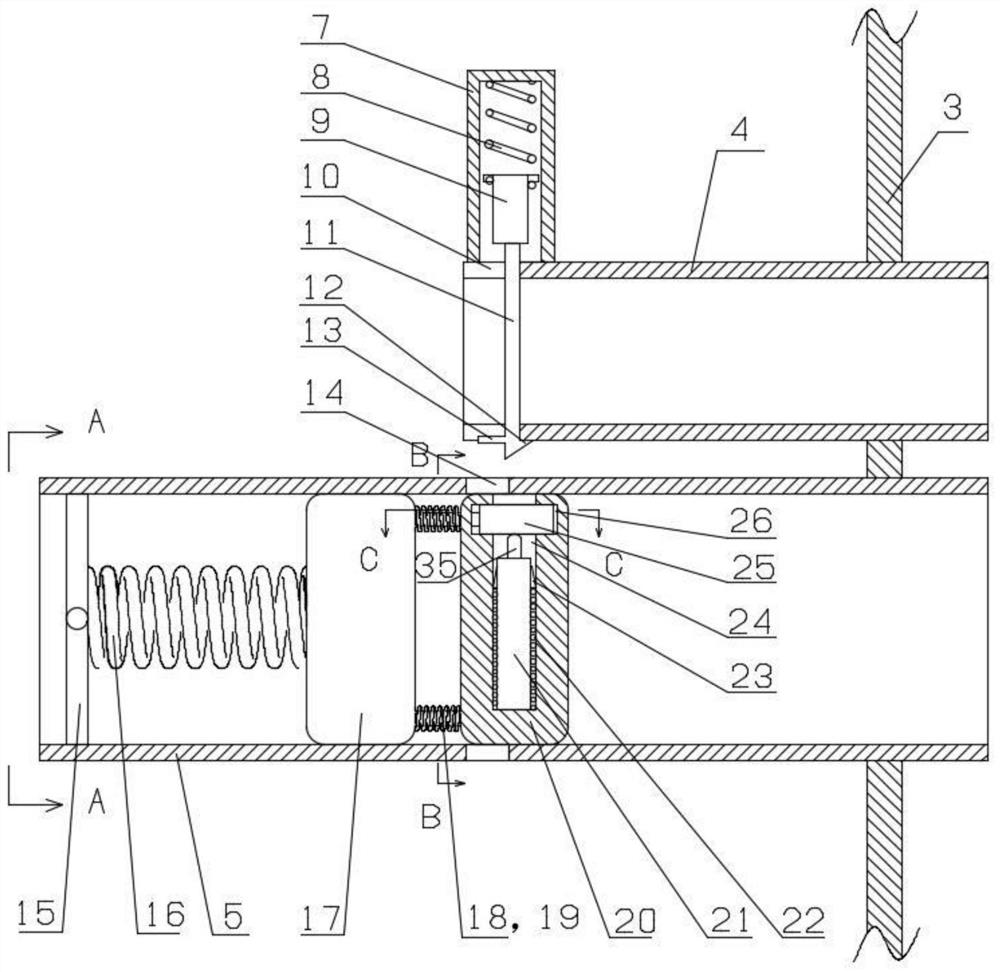

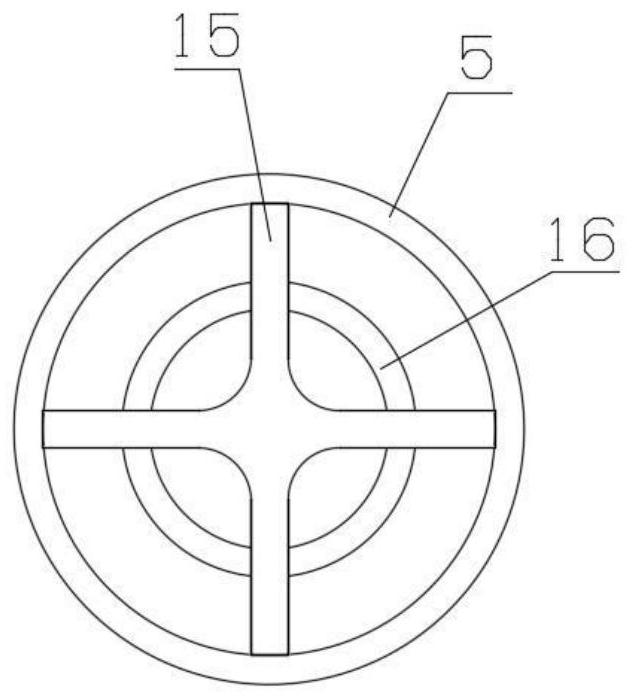

[0029]An oxygen tube 4 , an anesthesia tube 5 and a waste gas tube 6 inserted into the breathing zone 34 are sequentially arranged on the breathing mask 3 from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com