Method for treating sulfonation tail gas generated during production of water reducing agent from naphthalene

A technology for tail gas treatment and water reducing agent, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high replacement frequency, difficulty in eliminating atmospheric pollution, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

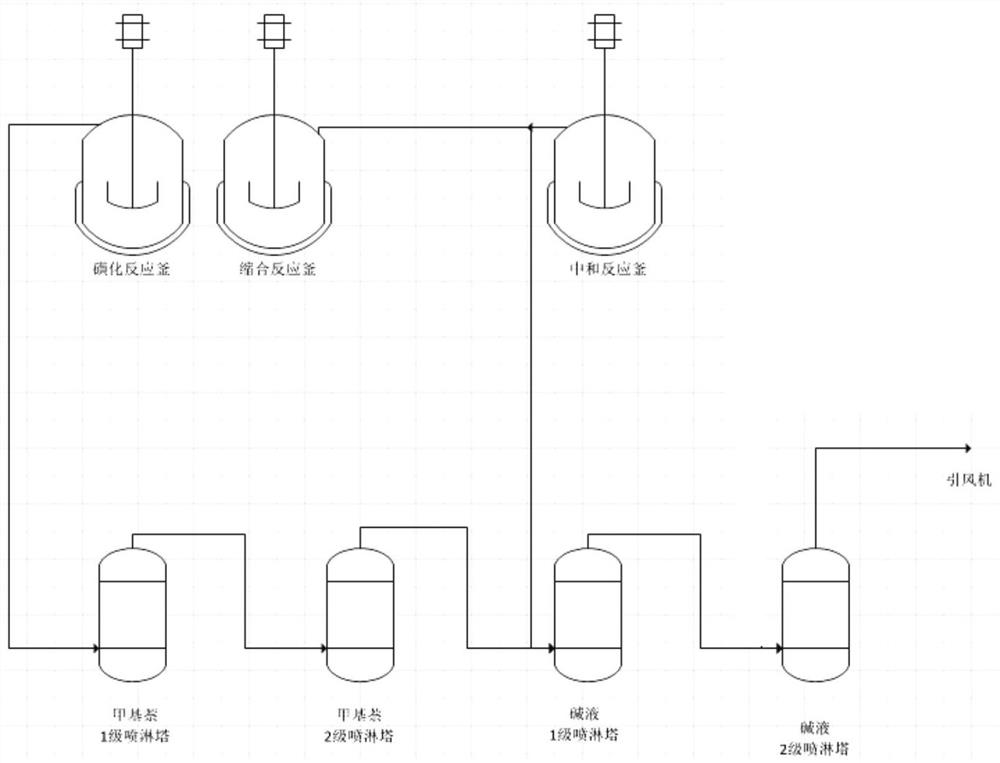

[0024] Embodiment 1: The method for the treatment of sulfonated tail gas produced when naphthalene produces water reducing agent, wherein, the method for producing water reducing agent from naphthalene is as above; The processing method of sulfonated tail gas comprises the following steps:

[0025] (1) Pass the tail gas in the sulfonation reactor into the first-level spray tower, spray methylnaphthalene with the first-level spray tower, and the methylnaphthalene spray flow rate is 2M 3 / H; Detect that the non-methane total hydrocarbon content in the tail gas of this 1st stage spray tower is: 13.4mg / m 3 , VOCs content: 7.35mg / m 3 ;

[0026] (2) The tail gas in the 1-stage spray tower is passed into the lye 1-stage spray tower, and the spray tower spray concentration is 32% liquid alkali, and the spray flow rate is 3M 3 / H. Detect the content of non-methane total hydrocarbons in the tail gas of the first-stage spray tower of this lye: 13.0mg / m 3 , VOCs content: 4.35mg / m 3 ....

Embodiment 2

[0032] Embodiment two: the method for the treatment of sulfonated tail gas produced when naphthalene produces water reducing agent, wherein, the method for producing water reducing agent from naphthalene is as above; The processing method of sulfonated tail gas comprises the following steps:

[0033] (1) Pass the tail gas in the sulfonation reactor into the first-level spray tower, spray methylnaphthalene with the first-level spray tower, and the methylnaphthalene spray flow rate is 1.5M 3 / H; Detect that the non-methane total hydrocarbon content in the tail gas of this 1st stage spray tower is: 13.4mg / m 3 , VOCs content: 7.35mg / m 3 ;

[0034] (2) The tail gas coming out from the 1-stage spray tower is further passed into the 2-stage spray tower, and the 2-stage spray tower sprays methylnaphthalene, and the spray flow rate is 1.5M 3 / H; Detect that the non-methane total hydrocarbon content in the tail gas of the first-stage spray tower is: 6.7mg / m 3 , VOCs content: 3.8mg / m ...

Embodiment 3

[0040] Embodiment three: the method for the treatment of sulfonated tail gas produced when naphthalene produces water reducer, wherein, the method for producing water reducer by naphthalene is as above; the treatment method of sulfonated tail gas comprises the following steps:

[0041] (1) Pass the tail gas in the sulfonation reactor into the first-level spray tower, spray methylnaphthalene with the first-level spray tower, and the methylnaphthalene spray flow rate is 2.5M 3 / H; Detect that the non-methane total hydrocarbon content in the tail gas of this 1st stage spray tower is: 13.4mg / m 3 , VOCs content: 7.35mg / m 3 ;

[0042] (2) The tail gas coming out from the 1-stage spray tower is further passed into the 2-stage spray tower, and the 2-stage spray tower sprays methylnaphthalene, and the spray flow rate is 3M 3 / H; Detect that the non-methane total hydrocarbon content in the tail gas of the first-stage spray tower is: 6.7mg / m 3 , VOCs content: 3.8mg / m 3 ;

[0043] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com