An environmentally friendly desulfurization equipment for industrial coal-fired boiler flue gas emission

A coal-fired boiler and flue gas emission technology, which is applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problem that coal-fired flue gas sulfide can not be fully contacted by desulfurization diluent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

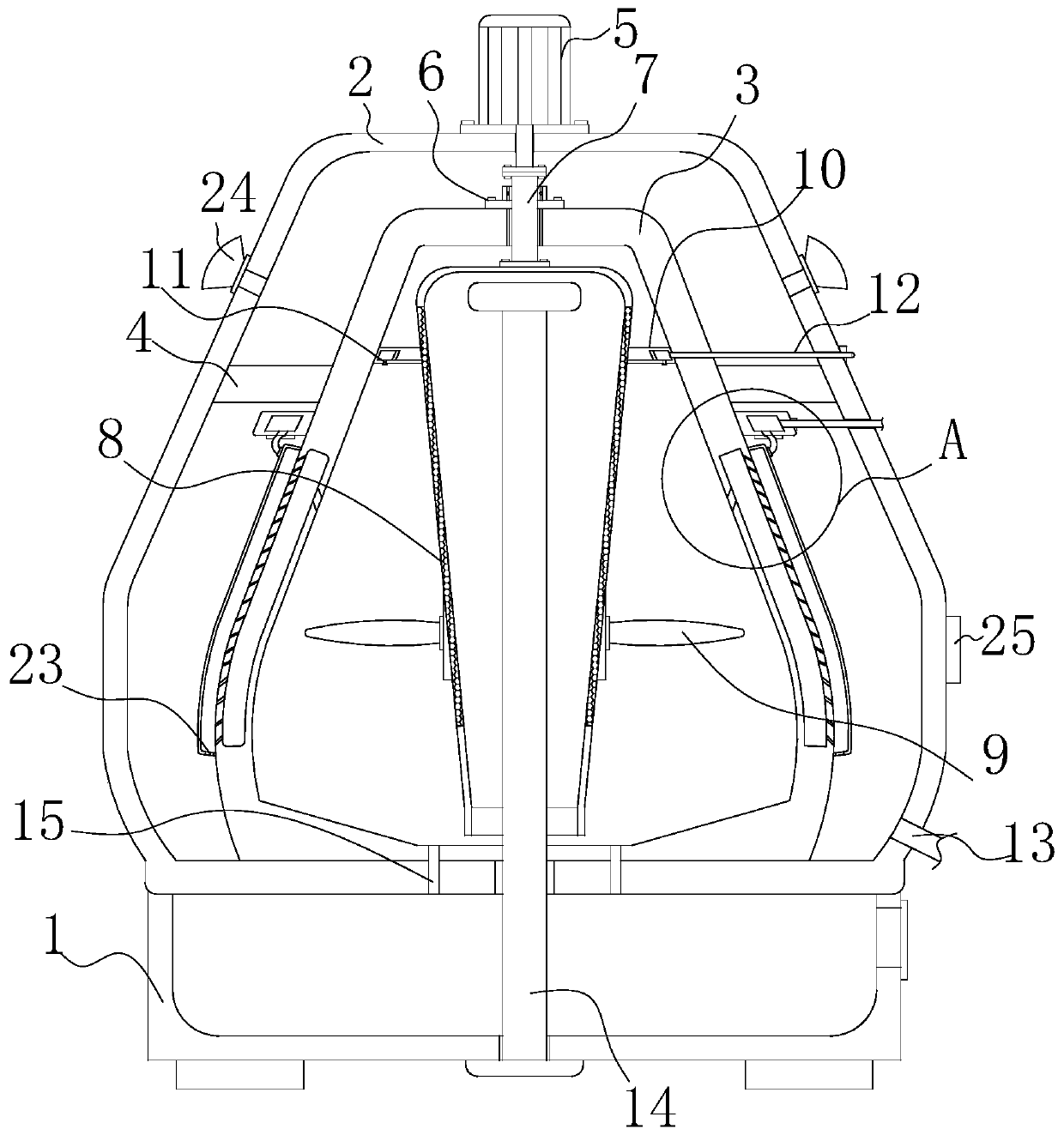

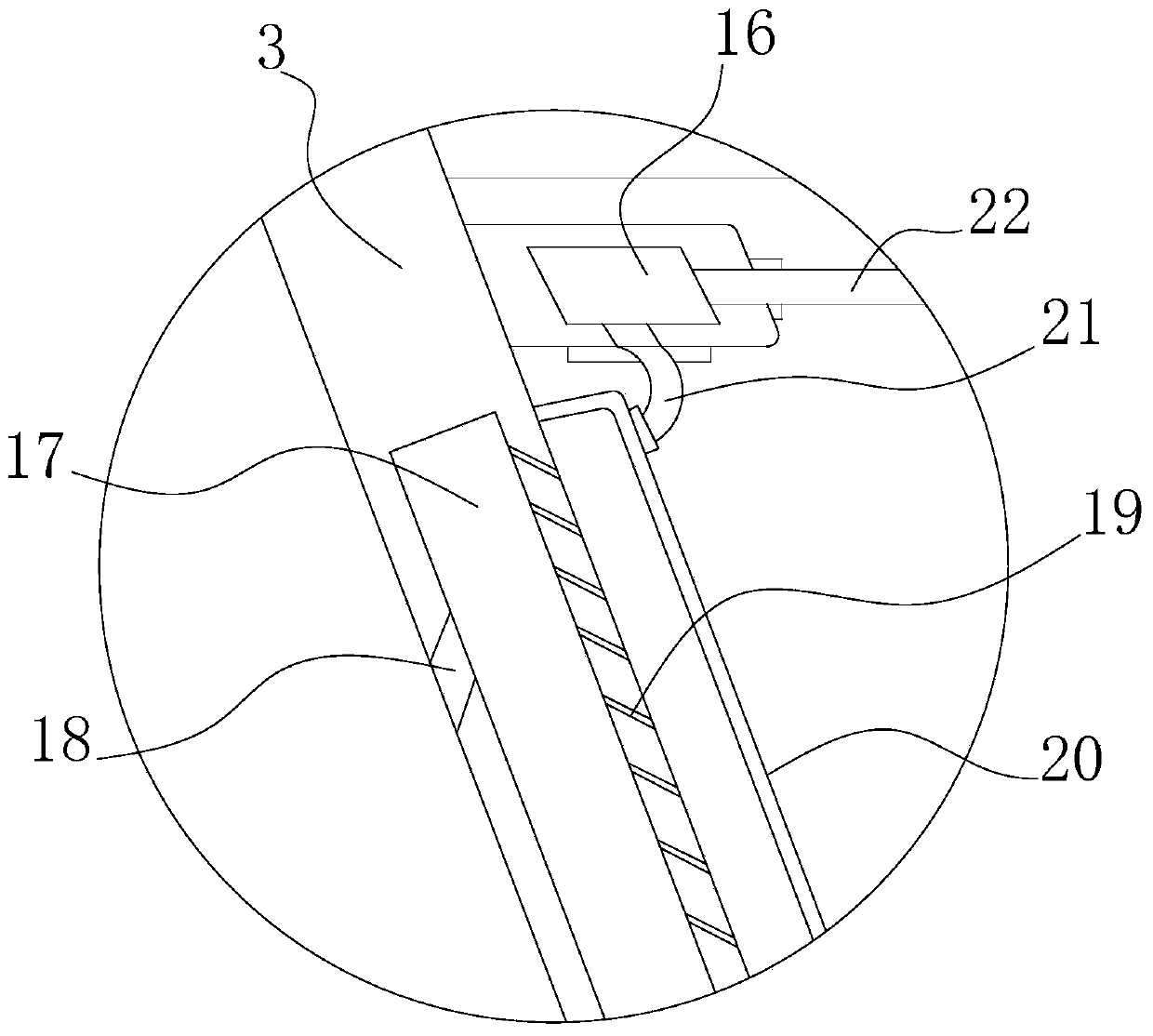

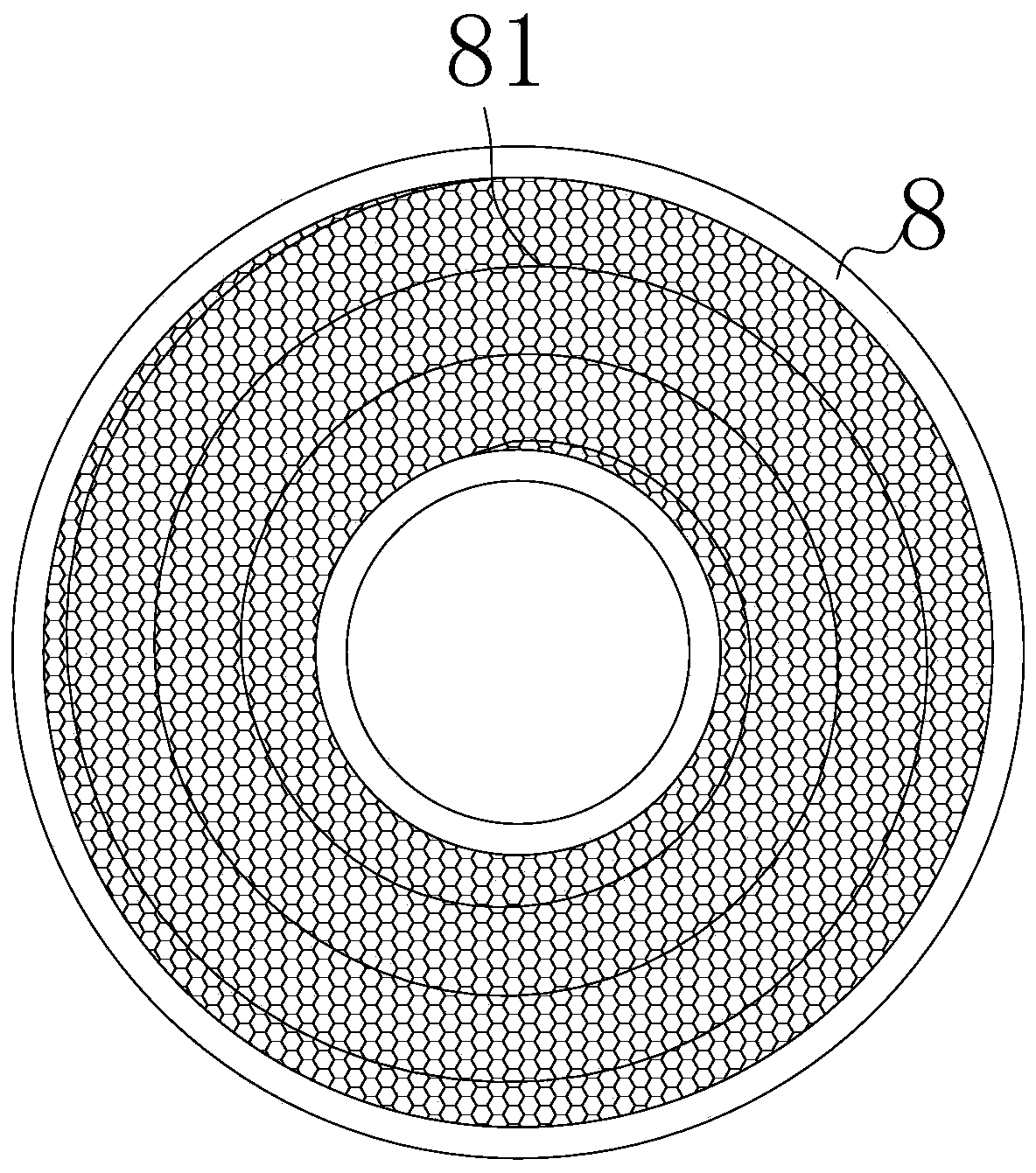

[0018] Such as Figure 1-3As shown, the present invention provides a technical solution: an environmentally friendly desulfurization device for industrial coal-fired boiler flue gas discharge, including a base 1, a body 2 is fixedly installed on the top of the base 1, and an inner casing 3 is fixedly installed on the inner bottom of the body 2 A dehydration layer 4 is fixedly installed between the inner side wall of the body 2 and the outer side wall of the inner casing 3, the dehydration layer 4 can be an activated carbon dehydration layer, and the middle position of the top of the body 2 is fixed with a drive motor 5 by bolts, and the drive motor 5 The output shaft runs through the top of the body 2 and extends to the inner side of the body 2. The middle position of the top of the inner casing 3 is fixed with a positioning bearing seat 6, and the end of the output shaft of the drive motor 5 is fixedly connected with a rotating shaft 7 through a coupling. The end of 7 runs th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com