Multi-step punch forming method capable of reducing part defects

A stamping forming, multi-step technology, applied in the field of stamping forming, to achieve the effect of ensuring processing accuracy, ensuring controllability, improving forming accuracy and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

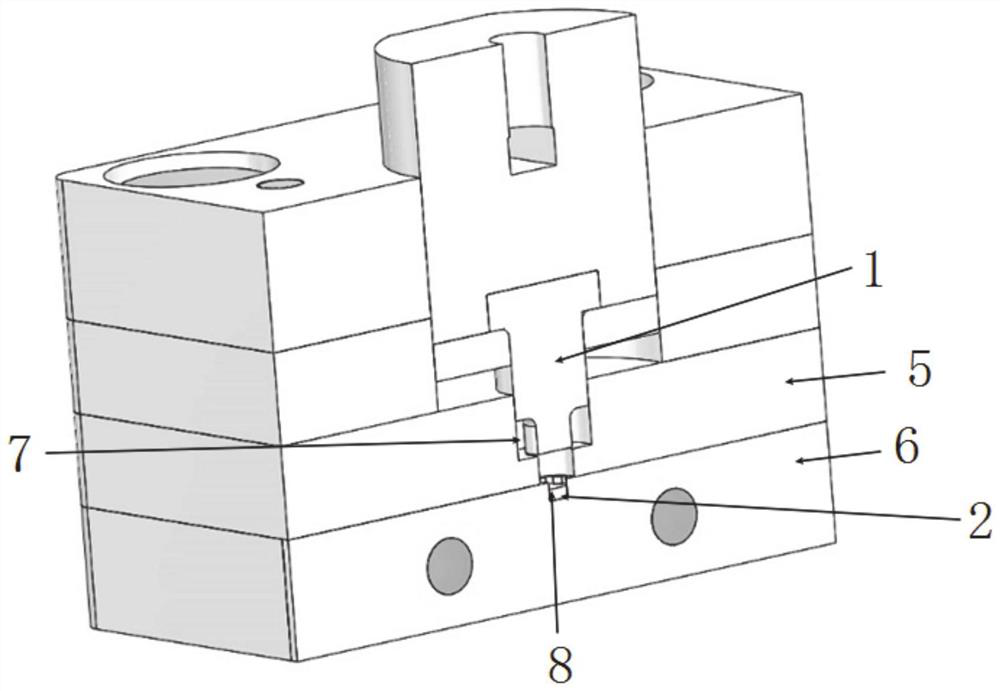

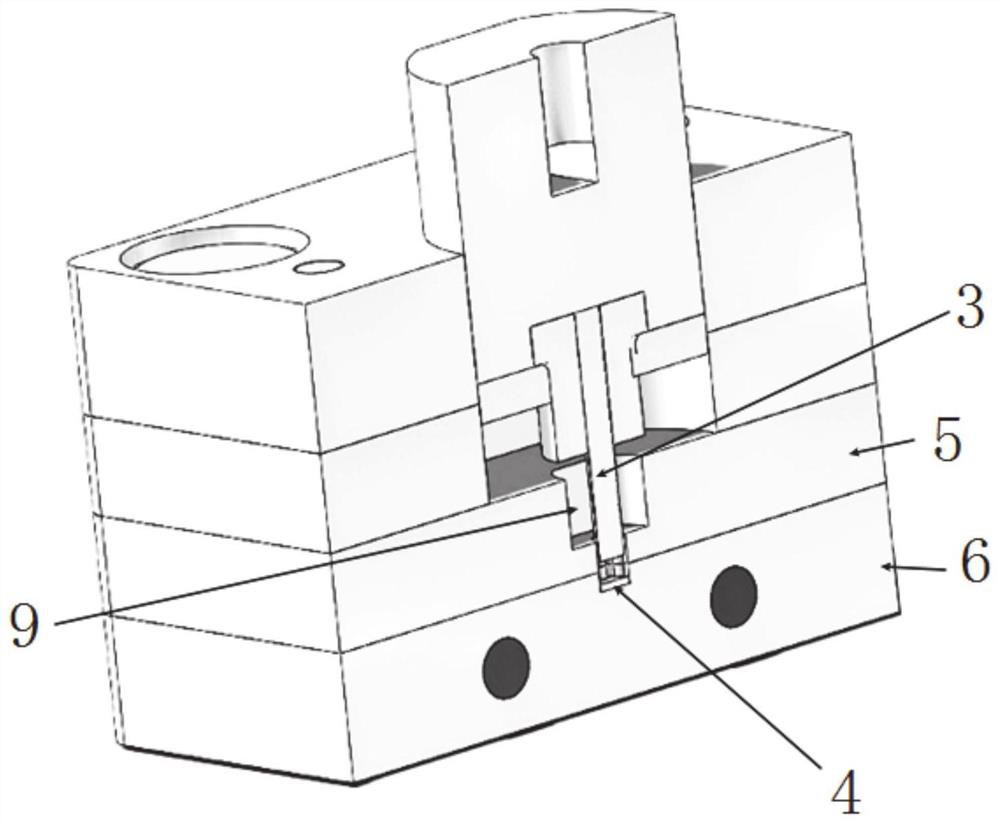

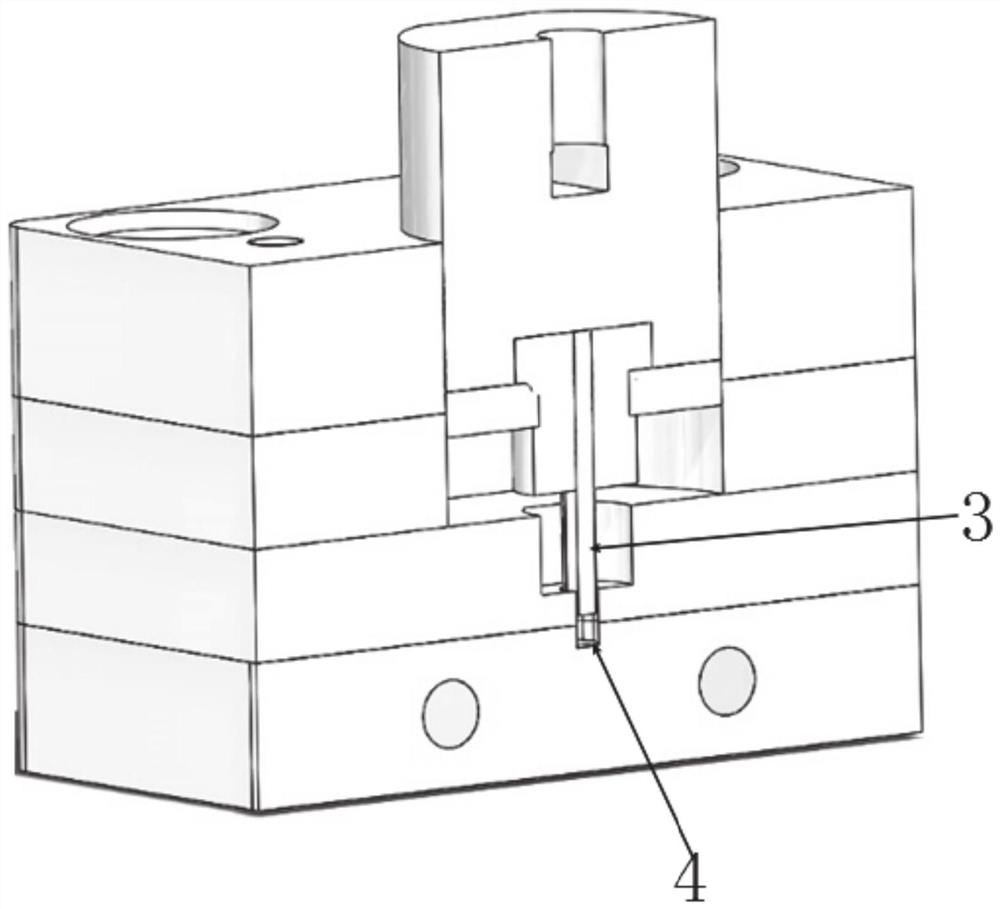

[0052] In a typical implementation of the present disclosure, such as Figure 1-Figure 19 As shown, a multi-step stamping method for reducing parts defects is provided.

[0053] Include the following steps:

[0054] Build forming dies and stamping mechanisms;

[0055] There is a mold cavity inside the forming mold, and the material is put into the mold cavity and formed under the action of the stamping mechanism;

[0056] The stamping mechanism includes a stamping output element and a stamping head. The stamping head moves under the action of the stamping output element, and the end acts on the material to deform it and form it under the constraints of the cavity. The stamping head includes the first punch 1 and the second punch. head 3;

[0057] The first through hole with different radial cross-sectional area is arranged to communicate with the second blind hole to form a stepped hole cavity 9, and the first gasket 2 is placed at the bottom of the second blind hole;

[005...

Embodiment 2

[0084] In another typical implementation of the present disclosure, such as Figure 1-Figure 19 As shown, a multi-step stamping forming method to reduce part defects is proposed.

Embodiment 1

[0085] In conjunction with embodiment 1, specifically comprise the following steps:

[0086] Step 1: First punch the blank with the first round punch with a diameter of φ5 to form a part of the star-shaped outer contour and flange features to form a stepped structure.

[0087] Using a 1.25 mm thick star-shaped first gasket, the first punch displacement is 1.25 mm, and the axial length of the blank located in the second blind hole is 0.75 mm.

[0088] Step Two: Using a second punch with a star profile, a star hole feature is formed.

[0089] At this time, the second star-shaped gasket of 0.75 mm is used, the displacement of the second punch is 1 mm, the axial length of the blank in the second blind hole is 1.25 mm, and the star-shaped hole opened by the second punch is 1 mm deep. mm.

[0090] Step 3: Continue to use the second punch with a star-shaped profile, and replace it with a 0.25 mm star-shaped second gasket. The second punch continues to be displaced by 1 mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com