Liquid flow control sliding sleeve

A sliding sleeve and liquid flow technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problem of easily scratching the metal seal of the reversing valve, reducing the service life of the electric pump, increasing operating costs, etc. problems, to achieve the effects of less risk of running liquid erosion, lower operating costs, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

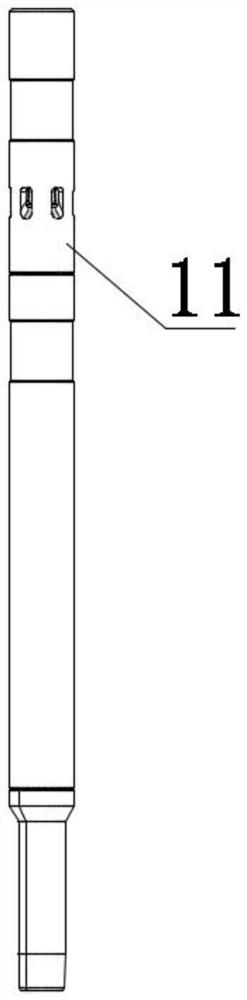

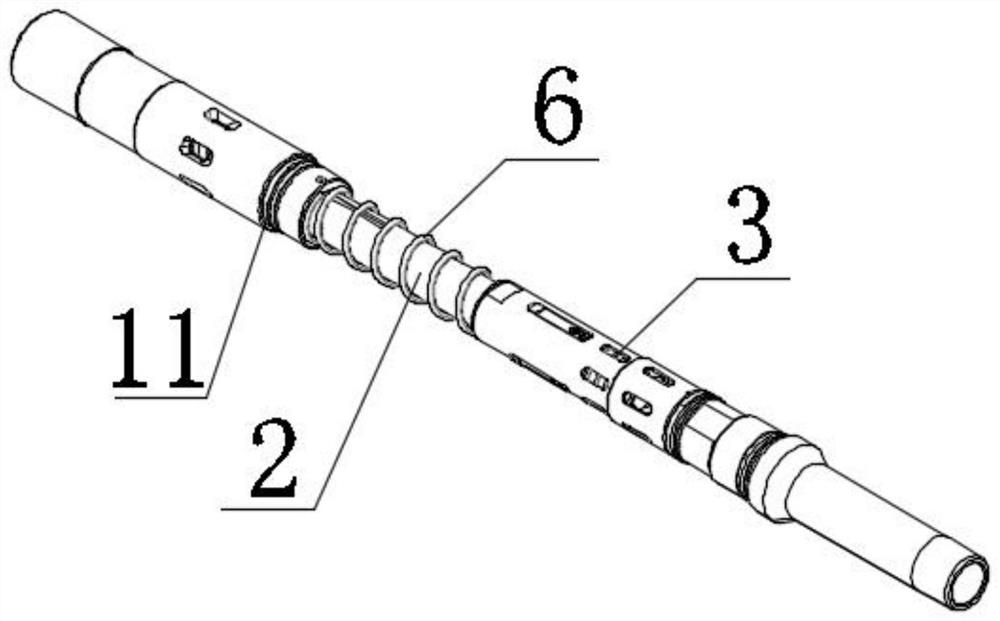

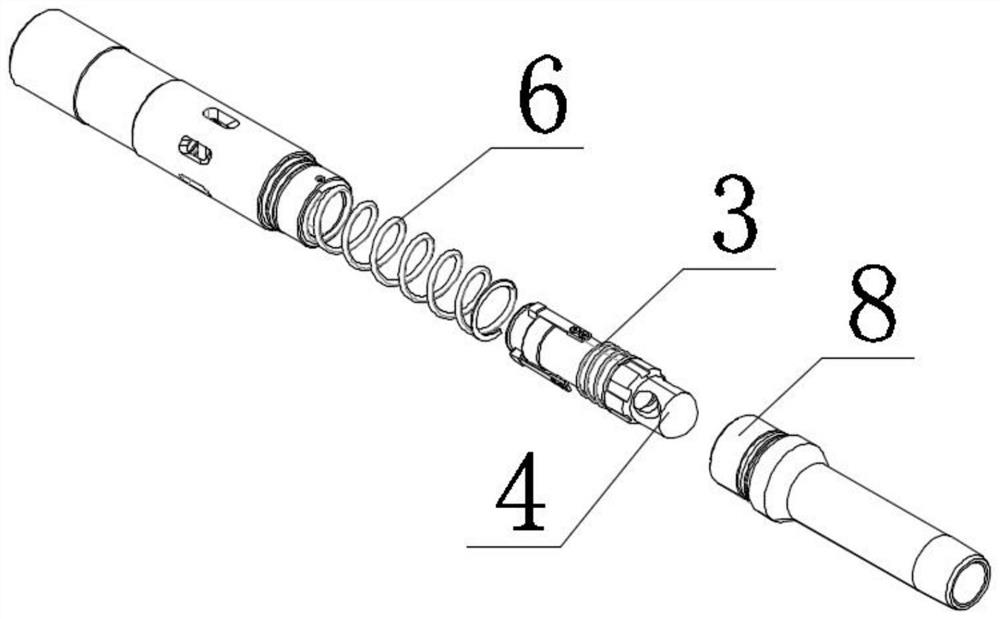

[0032] Such as Figure 1 to Figure 7 As shown, a fluid flow control sliding sleeve provided by a preferred embodiment of the present invention includes a central tube 2, and the upper part of the central tube 2 is slidably connected to an external pipe through a sliding sleeve body 1, and the sliding sleeve body 1 is connected to an external pipeline. The pipes are fixedly connected; the upper part of the central pipe 2 is provided with an annular pipe opening 9, and a sealing member 5 is provided at the connection between the annular pipe opening 9 and the central pipe 2; an oil outlet pipe 10 is set inside the central pipe 2; The outer middle part of the central tube 2 is wound with a second return spring 6, the bottom of the second return spring 6 is fixedly connected with the central tube 2, and the top of the second return spring 6 is fixedly connected with the sliding sleeve body 1; the central tube 2 The bottom of the center tube 2 is fixedly connected with a central ch...

Embodiment 2

[0040] In this embodiment, on the basis of Embodiment 1, the anchoring device 7 is replaced with a control ball, the central pipe 2 is provided with a central check valve control groove at the corresponding position, and the outer casing control tank is provided at the corresponding position on the inner wall of the external pipeline 11. groove.

[0041] At this time, the working principle of the present invention is: before starting the pump, the central check valve 4, the control ball and the center pipe 2 are locked together; The central pipe 2 goes upwards as a whole. After the annular pipe is closed, the control ball rolls into the control groove of the outer casing, and the central check valve 4 is released, and the fluid enters the oil pipe through the central check valve 4. When the pump is stopped, the central check valve 4 is released. The valve 4 is reset under the dual action of the first return spring 3 and the fluid pressure, the middle production channel is clos...

Embodiment 3

[0043] In this embodiment, on the basis of the first embodiment, the fluid flow control sleeve FCD (Flow Control Door) is applied to the electric submersible progressing cavity pump ESPCP (Electric Submersible Progressing Cavity Pum). ) and the electric submersible pump (ESP), the electric submersible screw pump combines the advantages of the electric submersible centrifugal pump and the screw pump, and the surface drive of the screw pump is directly driven by the motor through the reducer, and the sucker rod is removed , which solves the problems of sucker rod tripping, broken rod and eccentric wear; the working principle of this embodiment is similar to that of embodiment 1, but due to the working characteristics of the electric submersible screw pump, it is different from the When the electric submersible pump is reversed, the liquid flow direction is from bottom to top (inlet to outlet). This solution adds a check valve to solve the problem that when the electric submersibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com