Controllable electric supercharging device for engine

A technology of electric supercharger and electric supercharger, which is applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of engine economy decline, efficiency decline, increase intake resistance, etc., and improve low-speed response , to ensure efficiency, to avoid the effect of aerodynamic lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

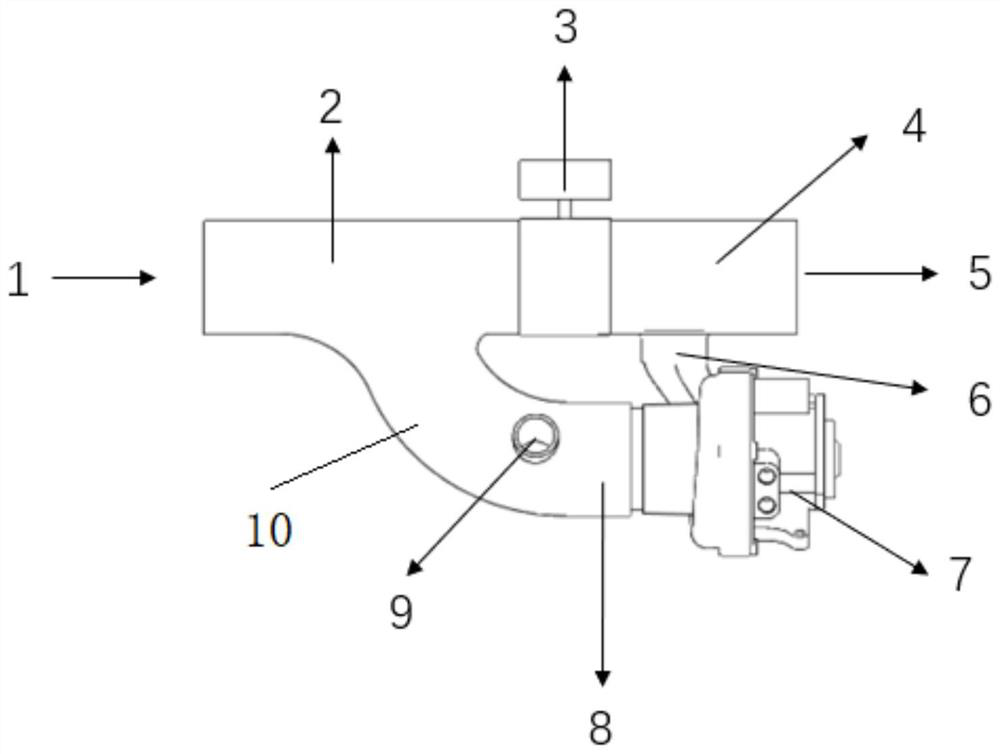

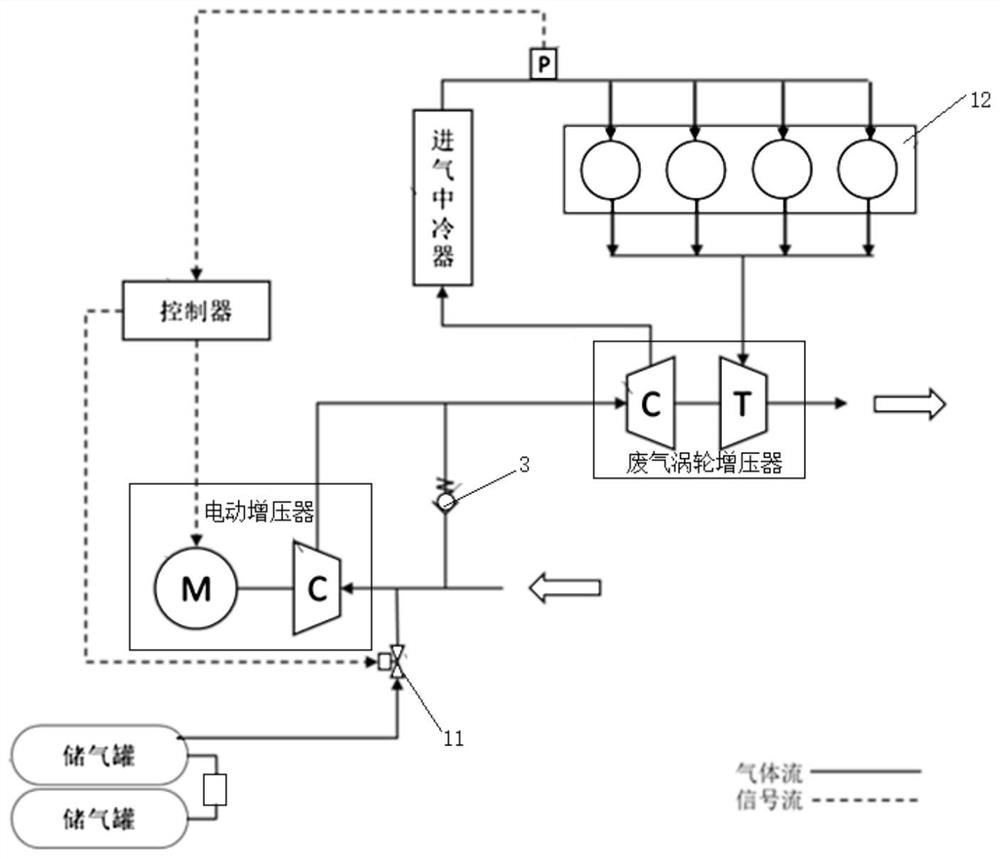

[0025] Such as figure 1 As shown, the present invention provides a controllable electric supercharging device for an engine, which is characterized in that it includes a connecting pipe on which an electric control valve 3 is arranged, and the electric control valve 3 divides the connecting pipe into the first connecting pipe 2 and the second connecting pipe 4; the port of the first connecting pipe 2 is used as the inlet 1 of the electric supercharger, and the port of the second connecting pipe 4 is used as the outlet 5 of the electric supercharging device; the side of the first connecting pipe 2 extends outward A third connecting pipe 10 is formed, and the third connecting pipe 10 communicates with the first connecting pipe 2; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com