Hollow blade pressing device and method

A technology of hollow paddles and paddles, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem of affecting manufacturing quality and work efficiency, worrying about the quality of weld bead appearance, disorder and safety Hidden dangers and other problems, to achieve the effect of reducing safety hazards, reducing safety hazards, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

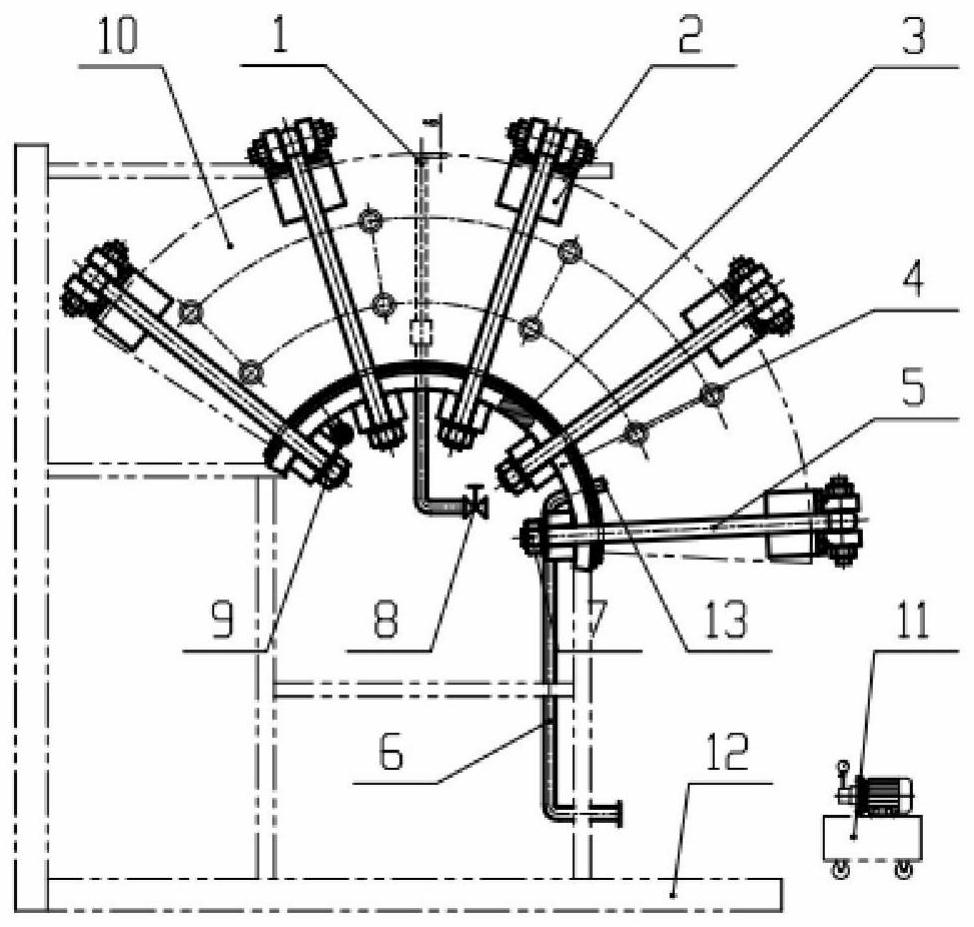

[0022] Embodiment 1: as figure 1 As shown, a hollow blade pressing device, the sealing gasket 3 is connected to the joint bolt 5 through the nut 7, the joint bolt 5 is connected to the blade 10 through the clip 2, the sealing gasket 3 and the blade 10 form a fan surface, and the arc The support plate 4 is connected with the paddle 10, the arc support plate 4 and the exhaust pipe 1 are fixed on the bracket 12, one end of the water injection pipe 6 is connected to the pressure pump 11, and the other end of the water injection pipe 6 is connected to the water inlet on the arc support plate 13. One end of the valve 8 is connected to the exhaust pipe 1, and the pressure gauge pipeline interface 9 is connected to the pressure gauge.

[0023] The arc support plate 4 and the exhaust pipe 1 are fixed on a bracket 12, and the paddle 10 is fastened with 4 or 5 sets of clips 2 composed of joint bolts 5 and nuts 7. When the pressure pump is working, the clear water is injected The water p...

Embodiment 2

[0024] Embodiment 2: as figure 1 As shown, a hollow blade pressing device, the sealing gasket 3 is connected to the joint bolt 5 through the nut 7, the joint bolt 5 is connected to the blade 10 through the clip 2, the sealing gasket 3 and the blade 10 form a fan surface, and the arc The support plate 4 is connected with the blade 10, the arc support plate 4 and the exhaust pipe 1 are fixed on the bracket 12, one end of the water injection pipe 6 is connected to the pressure pump 11, and the other end of the water injection pipe 6 is connected to the water inlet on the arc support plate One end of the valve 8 is connected to the exhaust pipe 1, and the pressure gauge pipeline interface 9 is connected to the pressure gauge.

[0025] The arc supporting plate 4 and the exhaust pipe 1 are fixed on a bracket 12, and the paddle 10 is fastened with 4 or 5 sets of clips 2 composed of joint bolts 5 and nuts 7. Clean water is injected from the water injection pipe 6, and the paddles The...

Embodiment 3

[0027] Embodiment 3: as figure 1 As shown in Fig. 1, a hollow paddle pressing device, on a fixed support structure, the tested paddle is placed on it, and the pressing implementation process is completed. The pressed paddle is installed vertically, and the water inlet pipe and exhaust pipe are located at the bottom. .

[0028] A hollow paddle pressing method. First, the pressed paddle is installed on the bracket, and the fastening work is completed and confirmed; when entering the pressing operation process, the operator must stand on both sides of the fan-shaped plate; after the pressing is completed, dismantle the five groups Clip, remove the paddle that has been pressed, and replace the next set of paddles to be pressed.

[0029] It includes the following steps: install the bracket connecting the water inlet pipeline, exhaust pipeline and pressure gauge pipeline on the support structure, and install it firmly; the pressed paddle is placed on the arc support plate of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com