Method for identifying plastic mechanical parameters of metal material by adopting spherical indentation morphology

A technology of metal materials and plastic mechanics, which is applied in the direction of testing material hardness, preparation of test samples, electrical digital data processing, etc., can solve the problem that iterative calculation does not converge, and it is difficult to use it to judge the uniqueness of identification results. The credible distribution interval of material properties and other problems to achieve the effect of avoiding the numerical iteration process, avoiding the simulation calculation process, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

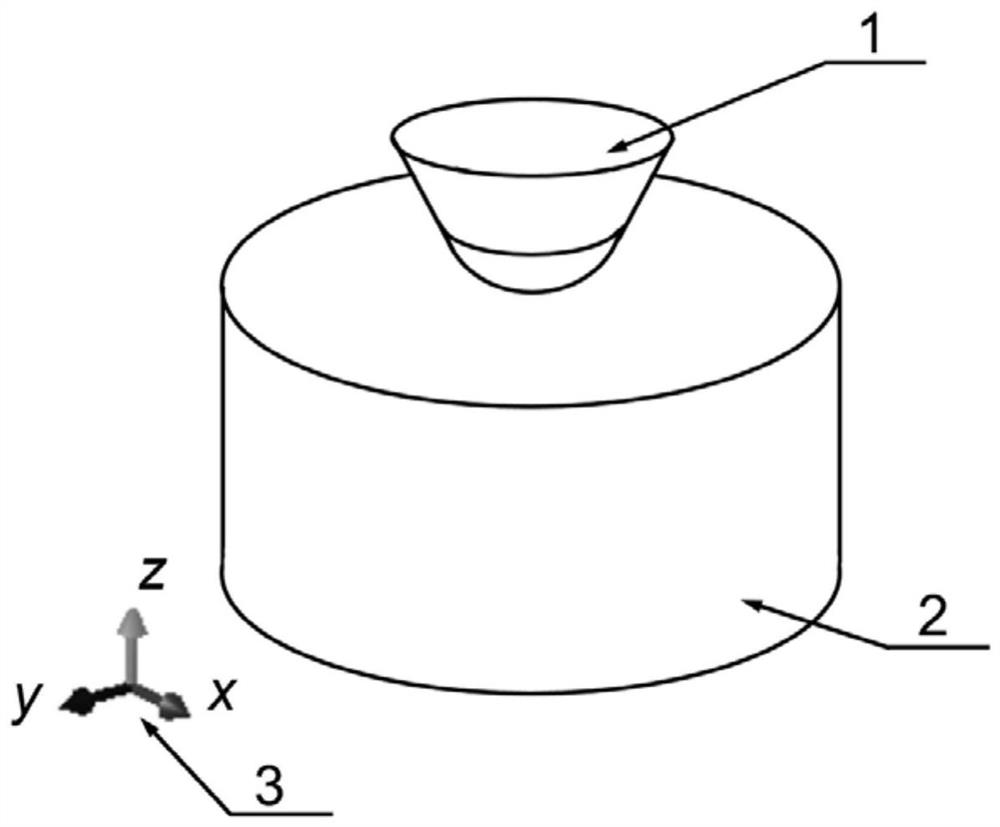

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments applied to 2099-T83 aluminum-lithium alloy materials. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as limitations to the present invention. .

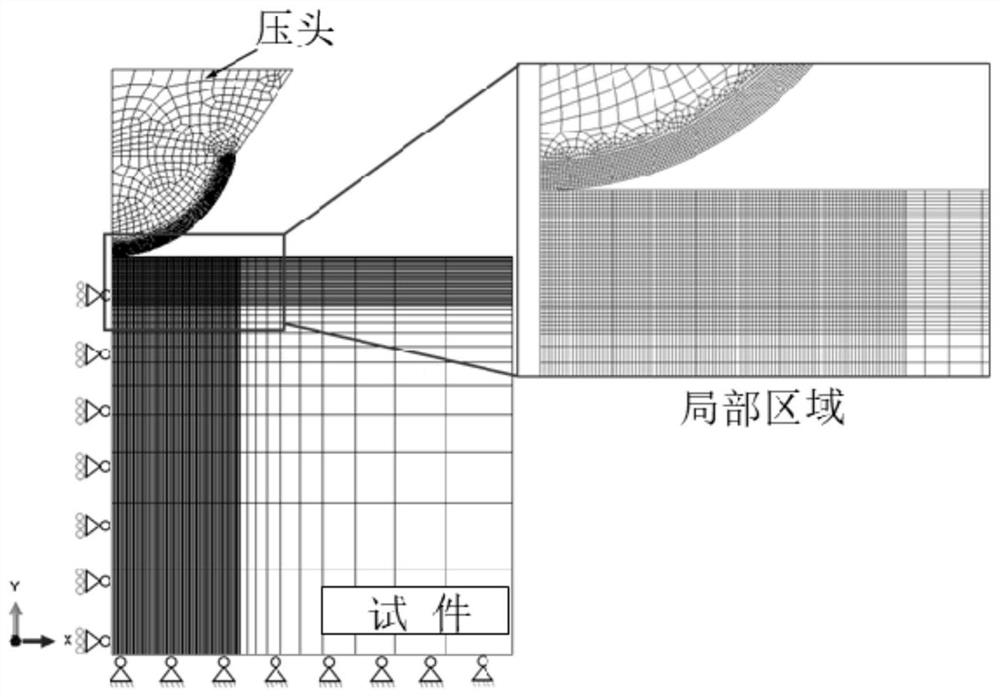

[0042] The present invention adopts the method for identifying the plastic mechanical parameters of metal materials by spherical indentation morphology, comprising:

[0043] Step 1: The surface of the metal sample to be tested is polished, and a spherical indentation test is carried out. The spherical indentation test was carried out under the Brinell hardness tester, and the loading method was load control mode.

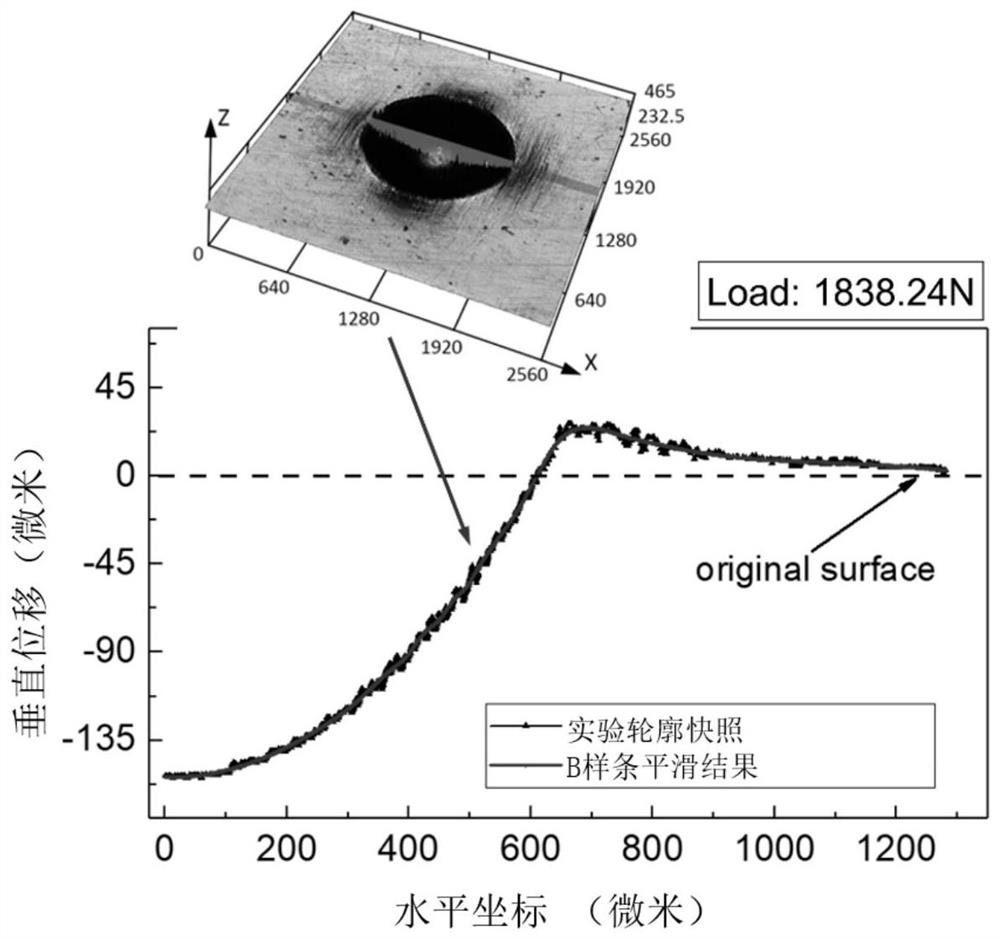

[0044] Step 2: After the indenter is unloaded, the profile of the spherical indentation remaining on the surface of the test piece is used to obtain a snapshot S of the profile of the indentation remaining on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com