Internal heat exchange cycle control method for battery swap station

A technology of cycle control and internal heat exchange, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of easy heat accumulation, easy heating and damage of charging modules, etc., to increase temperature, reduce heat concentration, avoid The effect of reducing the charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

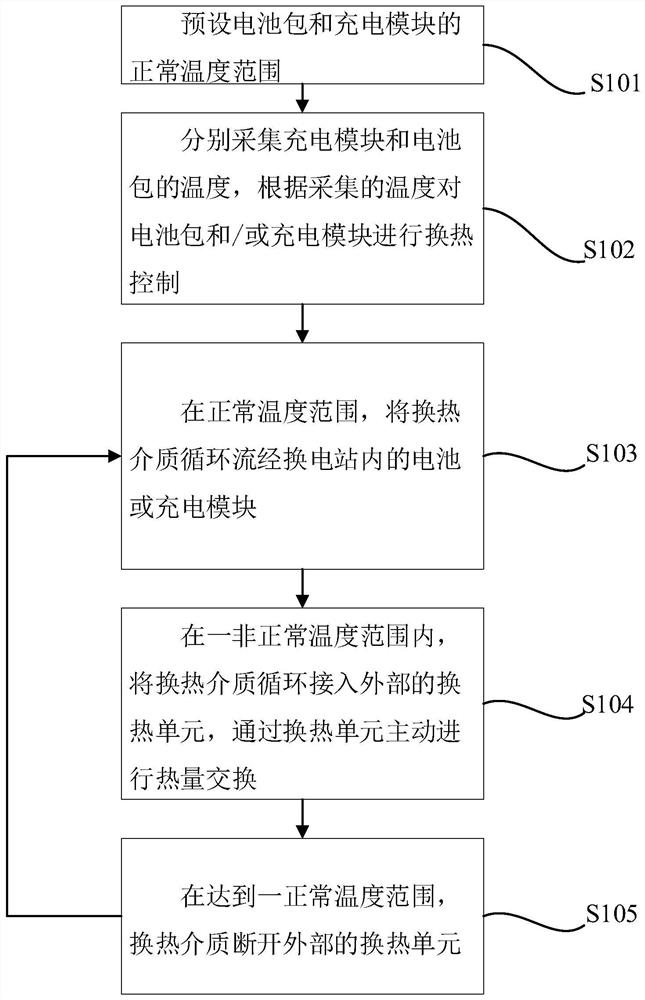

[0029] Such as figure 1 As shown, the present invention discloses a method for controlling the internal heat exchange cycle of a power exchange station, wherein the method for controlling the internal heat exchange cycle of a power exchange station includes the following steps:

[0030] Step S101, preset the normal temperature range of the battery pack and the charging module;

[0031] Step S102, collect the temperature of the charging module and the battery pack respectively, and control the heat exchange of the battery pack and / or the charging module according to the collected temperature;

[0032] Step S103 , in the normal temperature range, circulate the heat exchange medium through the battery or the charging module in the power exchange station.

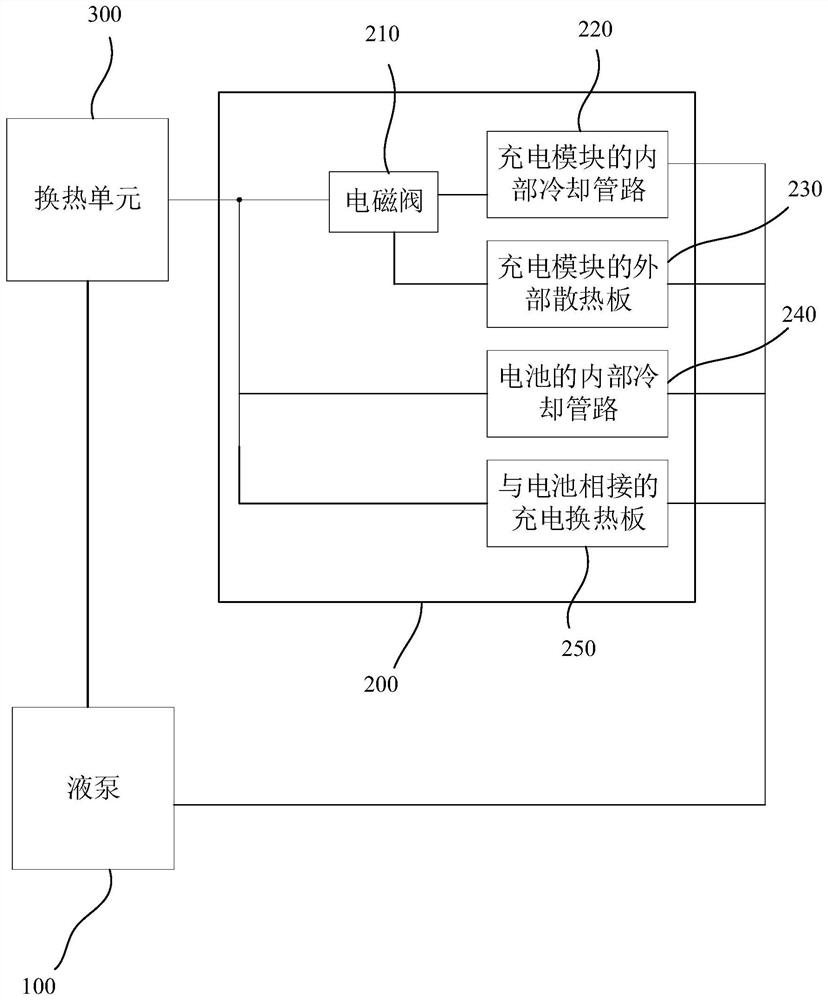

[0033] In the present invention, the charging module is arranged separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com