A new type of tower-type solar heat absorber heating surface module

A technology for solar heat absorbers and heating surfaces, which is applied to solar heat collectors, components of solar heat collectors, solar thermal energy, etc., and can solve the problem of cracking and failure of heat absorber tube panels and affecting tower-type solar thermal power generation systems Safe operation and other issues to achieve the effect of increasing the safety margin, reducing the difference in heating, relieving severe deformation and bearing excessive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

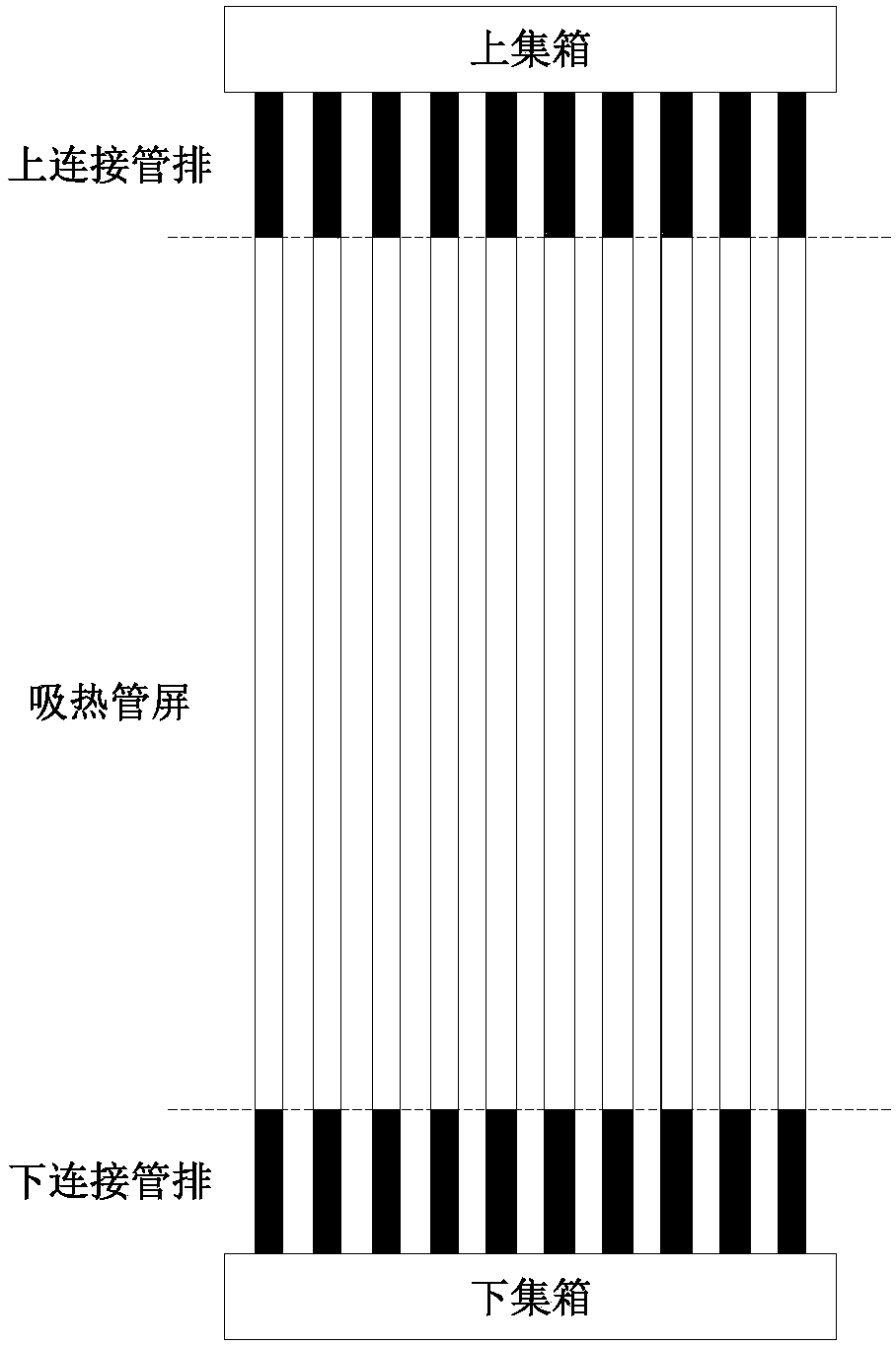

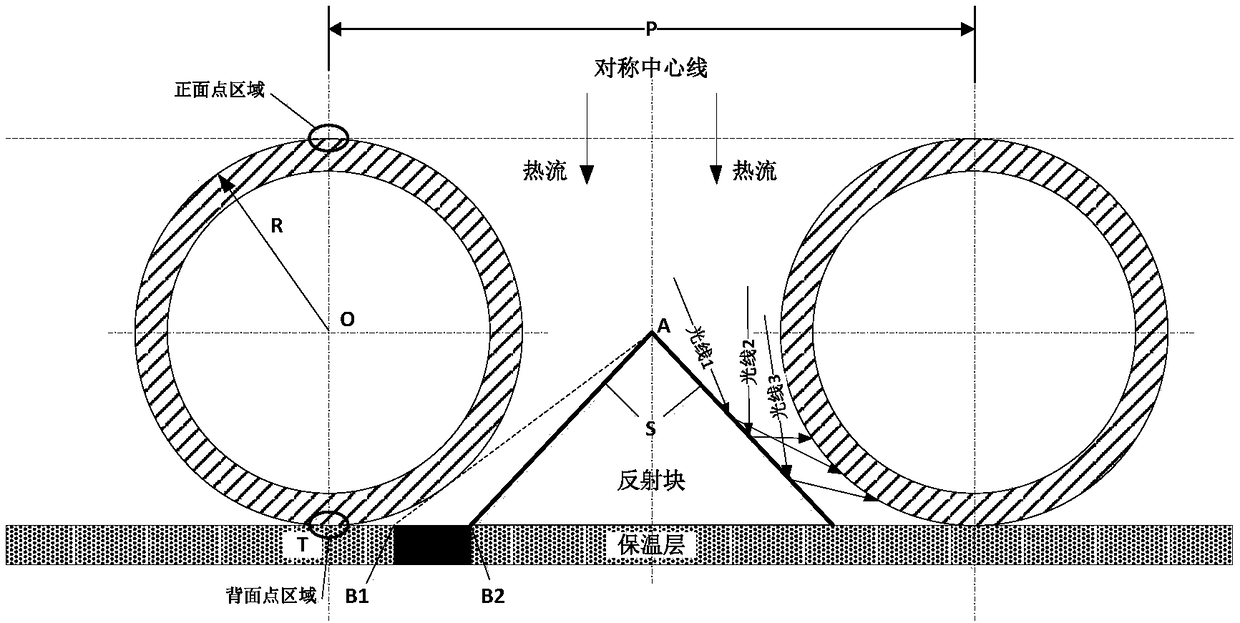

[0030] A kind of tower type solar heat absorber evaporates heating surface module, comprises lower header, lower connecting pipe row, upper connecting pipe row, upper header, and heat-absorbing tube panel (such as figure 1 shown). The lower end of the heat-absorbing tube panel is connected to the lower header through the lower connecting tube row. The upper end of the heat-absorbing tube panel is connected to the upper header through the upper connecting tube row. The distance between the centerlines of adjacent tubes of the heat receiving tube panels of the heat absorber is 3.2R (R is the outer radius of the tubes). The cross-sectional schematic diagram of the heat-absorbing tube panel structure is as follows figure 2 shown. The back of the heat-absorbing tube panel is provided with an insulating layer, and the outer boundary of the insulating layer is tangent to the vertex T of the backlight surface of each tube of the heat-absorbing tube panel. A wedge-shaped convex re...

Embodiment 2

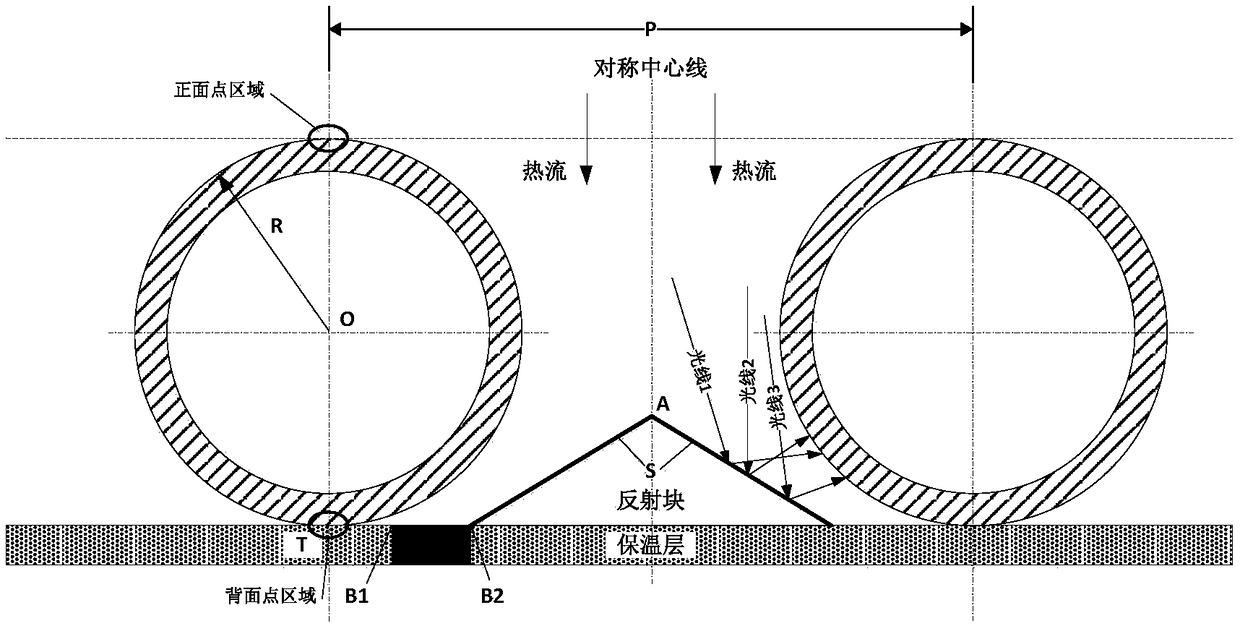

[0040] Compared with Embodiment 1, this embodiment is the same as Embodiment 1 except that the distance from the apex A of the reflective block to the heat preservation layer is 0.25R. Similar effects can also be obtained in this embodiment. The cross-sectional schematic diagram of this embodiment is as image 3 shown.

Embodiment 3

[0042] Compared with Embodiment 1, this embodiment is the same as Embodiment 1 except that the distance from the apex A of the reflective block to the heat preservation layer is 0.6R. Similar effects can also be obtained in this embodiment. The cross-sectional schematic diagram of this embodiment is as Figure 4 shown.

[0043] Since the sunlight received by the heat receiving tube panel of the solar heat absorber comes from the reflection of sunlight by mirrors at different angles, at the same time, the sunlight received by the tubes of the heat absorber tube panel and their intervals comes from different angles, Not the original parallel sun light. Therefore, the indication of light in different directions here is appropriate and in line with the actual working conditions of the heat sink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com