Building material production equipment with environmental protection function

A technology for building materials and production equipment, applied in sawing equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of increasing worker fatigue, collecting, scratching people, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

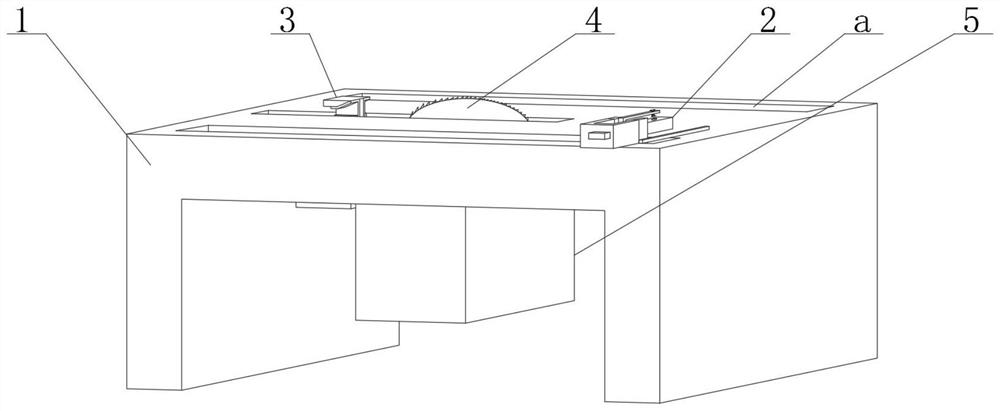

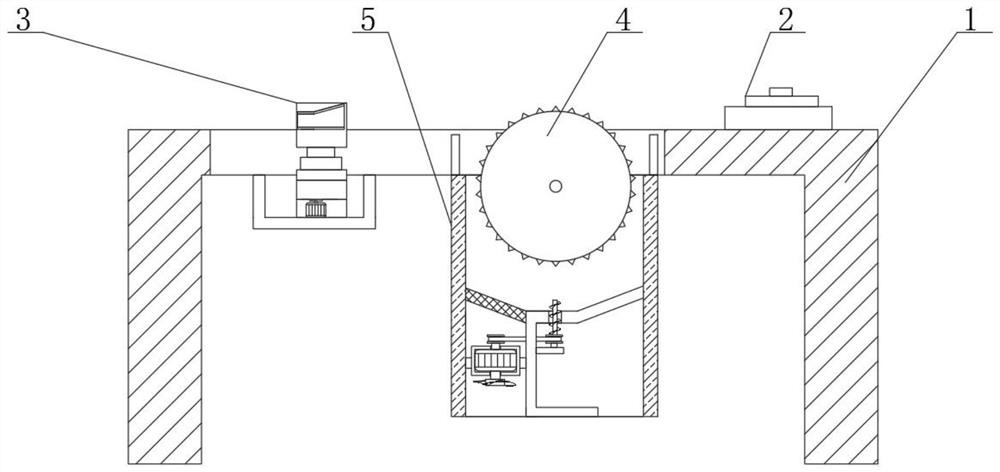

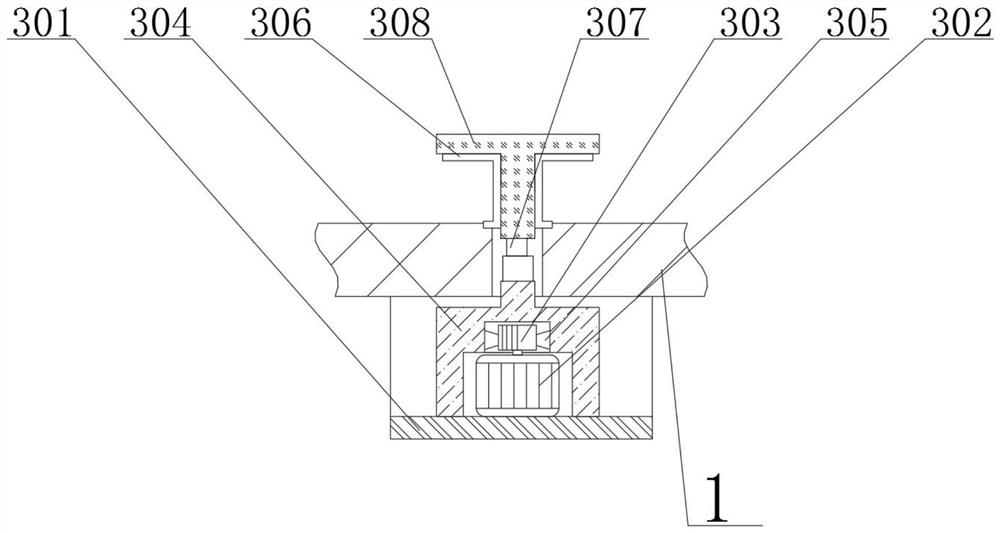

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 and Figure 9 , the present invention provides a technical solution:

[0032]A building material production equipment with environmental protection function, comprising a bracket 1, a positioning device 2, a grinding device 3 and a scrap collection device 5, a chute a is opened on the top surface of the bracket 1, and a positioning device 2 is slidably connected to the inside of the chute a, The positioning device 2 includes a first slider 201, a first fixed frame 202, a second slider 203, a support rod 204, a first handle 205, a first threaded shaft 206, a pressing block 207, a second threaded shaft 208, and a second handle 209 , spring 210 and support block 211, the inside of the front end chute a is slidingly connected with the first slider 201, the right end of the first slider 201 is fixedly connected with the second millimeter scale 6, and the second millimeter scale 6 slides...

Embodiment 2

[0036] see figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 , Figure 8 and Figure 10 , the present invention provides a technical solution:

[0037] A building material production equipment with environmental protection function, comprising a bracket 1, a positioning device 2, a grinding device 3 and a scrap collection device 5, a chute a is opened on the top surface of the bracket 1, and a positioning device 2 is slidably connected to the inside of the chute a, The positioning device 2 includes a third slide block 212, a second fixed frame 213, a fourth slide block 214, a positioning block 215, a third threaded shaft 216, a third handle 217 and a first millimeter scale 218, and the inner side of the chute a is slidingly connected There is a third slider 212, the outer side of the third slider 212 is fixedly connected with the second fixed frame 213, the inner side of the third slider 212 is slidably connected with the fourth slider 214, and the fourth slider 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com